The Urethane Blog

Everchem Updates

VOLUME XXI

September 14, 2023

Everchem’s exclusive Closers Only Club is reserved for only the highest caliber brass-baller salesmen in the chemical industry. Watch the hype video and be introduced to the top of the league: — read more

April 18, 2024

Ashley Furniture founder Ron Wanek first Wisconsin Manufacturing Hall of Fame inductee in 50 years

- RACHEL MERGEN

- Apr 5, 2024

RACHEL MERGEN

All his life, Ashley Furniture Industries founder and chairman Ron Wanek wanted to work in manufacturing.

Now, he is on an exclusive list of those who have made a lasting impact on the sector in Wisconsin.

In February, the Arcadia businessman was inducted into the Wisconsin Manufacturers & Commerce’s Manufacturing Hall of Fame. He was the first inductee added to the Hall of Fame since 1970.

“Wisconsin is a manufacturing state. It’s No. 2 in the United States as far as manufacturing jobs per capita,” Wanek said. “So what I’m saying is there’s a lot of manufacturers in Wisconsin, so I’m very honored.”

He said he did not expect to hear the Hall of Fame was set to expand.

“I was even more surprised when I found out I was the winner of it,” Wanek said.

Manufacturing family

Wanek was raised on a farm without indoor plumbing or electric lights near Lewiston, Minnesota.

“Manufacturing was always something that I wanted to do,” Wanek said.

A number of family members worked in manufacturing in Winona, Minnesota, he said. Eventually, he did too, starting with a job at Winona Industries in 1961.

Fast growth

He was able to learn and thrived at Winona Industries until he discovered an opportunity in 1970 to begin manufacturing occasional tables in Arcadia.

From there, he built Ashley Furniture Industries into the world’s largest manufacturer of home furnishings.

“That’s an impressive legacy for a company that only started 54 years ago,” Wisconsin Manufacturers & Commerce CEO Kurt Bauer said.

Bauer said Ashley Furniture has served as a huge employer and major economic engine in the western part of the state, helping other companies thrive through its supply chain.

The company has about 1,200 stores around the world, Wanek said.

Staying ahead

To stay strong, the company has made many changes through the years.

“We’ve had to constantly rebirth our organization,” Wanek said.

He said the company has implemented major changes to the way it operates 19 times. A big driver of those changes is the company’s mission to keep up with new technology.

Wanek said artificial intelligence and robotics currently are a focus for Ashley Furniture, along with making jobs easier for workers and remaining competitive.

Manufacturing in the US

Ashley Furniture also does all it can to keep its workforce in Wisconsin and the United States, Wanek said.

Philanthropy is also a priority for the Wanek family and Ashley Furniture, with over $45 million in donations since 2017 to science, technology, engineering and mathematics programs throughout the country.

Wanek said supporting diabetes and heart research programs has been a focus, along with planting trees throughout the country.

Wanek joins an impressive list of Hall of Fame inductees, including La Crosse native Reuben Trane, who founded Trane with his father, James.

Family-owned Ashley Furniture continues to grow far beyond its area home

Perfect fit for Hall of Fame

Bauer said Wanek matched the criteria for a rebooted Hall of Fame perfectly.

The Hall of Fame originally was started as the Industrial Hall of Fame in 1958 by the organization’s predecessor, the Wisconsin Manufacturers Association.

Wisconsin Manufacturers & Commerce — which was created when the Manufacturers Association and the Wisconsin State Chamber of Commerce merged — wanted to bring back the Hall of Fame to honor Wisconsin as a manufacturing state, Bauer said.

“We just thought it made sense to honor the history of manufacturing and the fact that it continues in the state of Wisconsin,” he said.

The newly restarted Hall of Fame’s criteria, Bauer said, includes a person’s economic impact, leadership, civic engagement, community philanthropy and enduring legacy.

“Mr. Wanek was at the top of the list in every one of those categories,” Bauer said.

April 18, 2024

Will Lihuayi Weiyuan Chemical’s New 300ktpa PO Facility Drive Market Prices Downwards?

PUdaily | Updated: April 18, 2024

Lihuayi Weiyuan Chemical Co., Ltd. has recently commenced production of its 300ktpa PO facility, with products passing inspection and now being sold externally. As a crucial extension of the company’s supply chain, the facility uses propylene and hydrogen produced from its propane dehydrogenation unit as raw materials. It maximizes the mutual supply and utilization of raw materials, products, and energy, representing another step in the company’s target of “building, extending, supplementing, and strengthening supply chain”. By enhancing the integrated utilization of materials and heat energy between units, it enables the extension of the industrial chain, further strengthening the chain’s resilience and enhancing the company’s competitiveness.

The start of this large-scale facility by Lihuayi Weiyuan Chemical undoubtedly breaks the current stalemate in Chinese PO market. On April 16, the prevailing offers of PO in Shandong and North China markets stood around CNY 9,050-9,100/tonne EXW in bulk in cash. Those in East China were CNY 9,400-9,500/tonne DEL in bulk in cash. Lihuayi Weiyuan Chemical is offering an ex-factory price of CNY 9,050/tonne, effective from April 16.

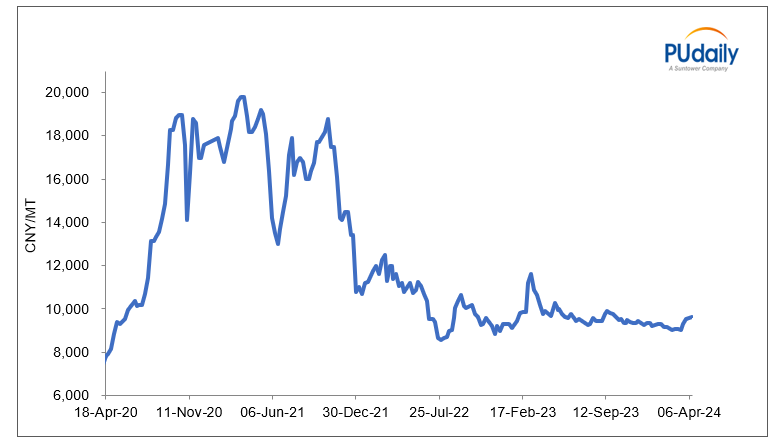

With continuously expanding capacity, China’s PO market is gradually becoming saturated. The additional 300ktpa capacity brought by Lihuayi Weiyuan Chemical further intensifies competition, putting downward pressure on the PO market. Chinese PO prices reached high levels in early 2020, peaking several times at CNY 20,000/tonne. The price increase was largely attributed to China’s growing domestic demand, the expansion of “dual-control” policy and power restrictions, facility maintenance in peripheral countries like Saudi Arabia and Singapore, and force majeure for polyether polyols and PO in the U.S. By the latter half of 2021, China’s downturn in the real estate sector caused PO prices to decline continuously to around CNY 9,000/tonne. The real estate industry, the largest downstream sector for the chemical industry, contributes a significant consumption share. The prosperity or downturn of the real estate sector directly and significantly impacts certain important chemical products. Factors such as the real estate downturn, slower macroeconomic growth, and sluggish industrial activity exert pressure on the PO industry chain.

In 2023, China’s PO capacity reached 6.1mtpa, marking a new high in recent years, according to PUdaily. Lihuayi Weiyuan Chemical’s new 300ktpa PO facility will further aggravate market competition and drive prices downwards.

Figure 2: China PO Price Trend 2022-2024

In general, Lihuayi Weiyuan Chemical’s new 300ktpa PO facility has had a short-term impact on market prices. However, in the long run, it will propel technological advancements and industrial upgrades, injecting new momentum for sustainable industry development. This development serves as a reminder that businesses must innovate continuously and enhance core competencies to secure a strong position in the increasingly competitive market.

April 17, 2024

Market Prospects of TPU in Bicycle Tire Applications

PUdaily | Updated: April 11, 2024

Whether in terms of weight reduction or rolling resistance, inner tubes are one of the most cost-effective upgradable components on a bicycle. In response to the demands for weight and resistance reduction, TPU has been considered as a material for inner tubes. TPU inner tubes represent a new technological advancement in recent years. In 2020, Schwalbe introduced its Aerothan TPU Tubes, becoming one of the pioneering companies to launch TPU inner tubes. It also marks the official entry of this material into the commercial bicycle sphere.

Currently, the mainstream materials for inner tubes are butyl rubber, latex, and TPU.

Butyl inner tubes are the most widely used standard inner tubes in cycling. Made from elastic polymers, butyl inner tubes offer good stretch and rebound properties and are the most affordable option. Latex inner tubes fall in the mid-range in terms of cost, mostly produced from natural rubber. Latex rubber is more porous than butyl, meaning latex tubes lose air much more quickly. The price of latex tubes is typically 2-3 times that of butyl tubes.

TPU inner tubes are at the cutting edge and also the most expensive. As a flexible plastic, TPU excels in weight reduction. A typical butyl inner tube weighs around 140 grams (actual weight may vary slightly due to size and valve length), while a latex inner tube reduces that weight to approximately 85 grams. As for TPU inner tubes, the weight drops to just 25 grams. This means that the weight difference between two bicycles made of butyl rubber inner tubes and TPU inner tubes can reach up to 230 grams. This is why many professional cyclists opt for TPU inner tubes when competing.

Another obvious difference among different inner tubes is their rolling resistance. It’s found that the rolling resistance of the best butyl inner tubes still consumes about 3 watts more than TPU inner tubes and 4 watts more than latex inner tubes. In long-distance mountain climbing, a bicycle equipped with TPU inner tubes can increase power by 10 watts, equivalent to reducing weight by 2 kilograms.

Another trend nowadays is tubeless tires, which are tires without inner tubes. Compared to traditional clincher tires with inner tubes, tubeless tires have lower rolling resistance and better puncture protection. However, the high maintenance costs, difficulty in component assembly and replacement, and the risk of air leakage or even tire separation still raise concerns.

China’s bicycle output reached around 100 million units in 2023, reflecting a significant growth potential for TPU inner tubes. Furthermore, Aerothan road tires launched by Schwalbe in July 2023, which replace rubber with nylon-coated TPU material in cover tyres, achieve comprehensive upgrade in puncture protection and weight reduction, potentially opening up new applications for TPU in tires.

April 17, 2024

Covestro takeover by oil group Adnoc still up in the air

April 17, 2024 at 01:02 pm

Share

LEVERKUSEN (dpa-AFX) – Talks on a possible takeover of the chemicals group Covestro by Abu Dhabi National Oil (Adnoc) continue to drag on. “We are conducting these talks in a constructive and open-minded manner in accordance with our obligations under stock corporation law – and in the interests of our company, our shareholders and all other stakeholders,” said Covestro CEO Markus Steilemann on Wednesday at the Annual General Meeting of the DAX-listed company from Leverkusen. Key points relating to the talks with the oil company from the United Arab Emirates thus remain open.

Speculation about a deal arose almost a year ago. It was only in September that Covestro announced that it was in talks with Adnoc. After several rumored increases in the offer, an informal offer of just over EUR 60 per share has been in the air for some time. The Bloomberg news agency reported on this sum in February, citing people familiar with the matter. In total, this would be more than 11.3 billion euros.

Covestro shares initially benefited from speculation about interest from the golf group. In June 2023, its price jumped by around a quarter to around 50 euros. The bottom line is that not much has happened since then. Investors are concerned that the share price will fall again significantly if negotiations with the state-owned company fail, despite the recent slight improvement in the outlook for the chemical industry./mis/stw/jha/

April 16, 2024

Korean petrochemical industry on alert as naphtha price soars

0

|

| [Graphics by Song Ji-yoon] |

| <이미지를 클릭하시면 크게 보실 수 있습니다> |

South Korea’s petrochemical industry is closely monitoring the developments in the Middle East as the price of petrochemical raw materials could soar further on intensifying tension.

According to the Ministry of Trade, Industry and Energy on Monday, the price of naphtha stood at $717 per ton as of April 5, up 8.3 percent from February.

Naphtha is a key raw material that accounts for a significant portion of the cost of petrochemical products.

The Korean petrochemical industry uses naphtha generated during the oil refining process to produce basic products such as ethylene and propylene.

For ethylene, about 80 percent of the selling price is used to procure naphtha.

The recent upward trend in oil prices has been blamed for the rise in naphtha prices.

According to the Korea International Trade Association, prices of the country’s benchmark Dubai crude reached $90.48 per barrel, marking the highest level since October 2023.

Prices rose by 11.3 percent from the average price of $81.3 in the first quarter of 2024.

Dubai crude oil prices are projected to rise to more than $100 per barrel if the Israel-Hamas conflict escalates.

The Strait of Hormuz, which Iran could blockade, is also a major export route for Saudi Arabia, which accounted for 31 percent of Korea‘s crude oil imports in 2023.

The petrochemical industry is concerned that rising costs will hurt profitability.

“In a supply-driven market, we can pass on cost increases to selling prices to maintain profitability,” said an industry insider. “But now it is the other way around. We are in a situation of oversupply. Any increase in production costs will immediately lead to a deterioration in profitability.”

China has ramped up its production capacity to become self-sufficient in petrochemical products, contributing to a global oversupply of more than 13 million tons over the past three years.

Global production gained 23.2 million tons from 2021 to 2023 while demand added only 10.21 million tons.

이 기사의 카테고리는 언론사의 분류를 따릅니다.

http://news.zumst.com/articles/90048175