Urethane Blog

Green Polyols from Chimcomplex

May 20, 2024

Chimcomplex Wraps Up €2.43M Project for Making Polyols from Natural Oils

Published on 2024-05-17. Edited By : SpecialChem

TAGS: Sustainability / Natural Solutions

Chimcomplex SA Borzești concludes the project to make the production processes ecofriendly and align the company’s activities with circular economy principles.

The project was implemented at the Rm Vâlcea plant. The total eligible value of the project is €2,431,000, with non-repayable financial assistance amounting to €1,215,000.

Green Polyols from Castor Oil, Soybean Oil, and Palm Oil

Investing in innovative technology for environmentally friendly polyol production was the next necessary step after the inauguration of one of Europe’s most modern polyol plants in 2022.

This €40 million investment increased the company’s production capacity to over 187,000 tons per year. These innovative “green polyols,” produced using the new technology, replace the petrochemical components of conventional polyols with less polluting alternatives or natural oils such as castor oil, soybean oil, and palm oil. Further down the production chain, these “green polyols” are used to create soft foams for pillows, mattresses, and other automotive components.

The impact of this investment is significant:

- The new production line will allow Chimcomplex to increase its existing capacity by an additional 17,000 tons of special polyols annually. After client testing, these new polyols will enter serial production, significantly reducing their environmental impact due to the nature of the technologies and raw materials used in manufacturing.

- Replacing conventional polyols with the new special types will reduce CO2 emissions by up to 3,400 tons annually.

- The company’s competitiveness will improve through portfolio expansion.

- The new facility enhances the company’s adaptability to customized product needs for individual clients. Product design will be done collaboratively with customers, adapting formulas based on their requirements.

- Current and future clients can purchase the new “Made in Rm. Vâlcea” polyols, reducing the carbon footprint of their final products and labeling them as environmentally friendly.

Amalia Ionescu, project manager, stated, “This new investment completed at the Rm. Vâlcea plant reflects the company’s commitment to sustainability, innovation, and development. We thank Innovation Norway for supporting the project. Over the past 5 years, Chimcomplex specialists from the Advanced Polyol Research and Development Center have created new experimental polyol types, which can now be rapidly tested and widely used by our clients. Fine chemicals add value to Romania overall and to consumers in particular. We all desire safer and healthier products for everyday use. You can rely on the expertise of chemists to find solutions for environmental challenges and develop technologies that reduce our planet’s negative impact.”

The project was carried out in partnership with International Development Norway, a Norwegian organization with over 20 years of experience in international projects focused on eco-business best practices.

https://chimcomplex.com/docs/press-releases/

HISTORY

1954

CHIMCOMPLEX was founded in Borzesti, Onesti, Bacau County.

1966-1970

In Râmnicu Vâlcea, was established in 1966 SC OLTCHIM SA under the name of Râmnicu Vâlcea Chemical Plant.

In the two industrial platforms, the needed installations were put into operation for chlorosodium products, oxo alcohols, vinyl chloride, polyvinyl chloride and HCH lindane, all based on foreign licenses.

1971-1980

At Oltchim takes place the development of the production profile from the first stage. New production capacities are put into operation and the product range is diversified with chlorinated solvents, propylene oxide, propylene glycols, polyethers, polyols, phosgene;

1981-1990

At Oltchim, new capacities were put into operation for organic intermediates (amines, chloroformates) and a wide range of pesticides.

1990

Successive investments take place in production at Borzești Chemical Plant: electrolysis, inorganic chlorides, solvents, PVC, alkylamines, and pesticides.

1991

The Borzești Chemical Plant becomes Chimcomplex SA Borzești with registration number at the trade register J04/493/1991. The financial capital was mostly owned by the state.

1991-1999

The products portfolio has been diversified on both platforms, over 40 basic products in over 78 assortments were developed. Thus we have been producing PVC, polyol polyether, plasticizers, pesticide formulas and formulas for processing plastic materials.

In 1997 Oltchim is listed on the capital market in the first category of the Bucharest Stock Exchange.

2000-2003

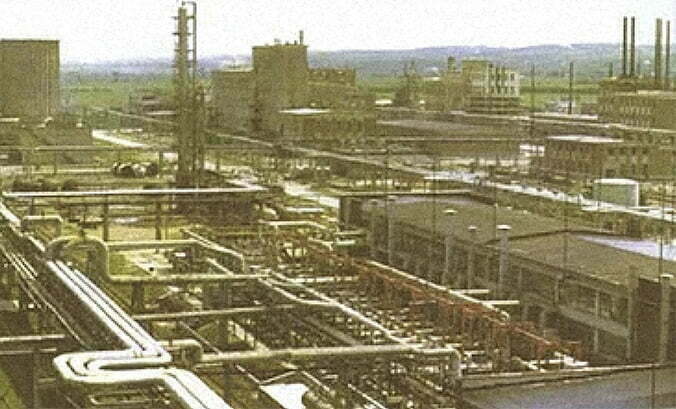

Meant the fulfillment of some strategic objectives for the development of Oltchim: modernizations (oxo-alcohols installation, ion exchange membrane electrolysis), commissioning of new installations (caustic soda flakes and pearls, phthalic anhydride, dioctyl phthalate, water demineralization, waste incineration) ) and capacity expansions to existing facilities (propene oxide, flexible polyols, PVC).

2003

Chimcomplex SA Borzești was privatized by Mr. Ștefan Vuza, saving it from bankruptcy. In the first three years, Ștefan Vuza made investments of over 25 million euro. Another 285 million euros were invested in the next 10 years. Mr. Vuza’s strategy also aimed at acquiring Oltchim, which will be the core of the Romanian Chemical Company.

2004-2012

At Oltchim, capacity modernizations and extensions were carried out at the existing technological installations: propene oxide, polyol-polyethers, PVC and a new waste incineration plant were put into operation, as well as an industrial lime plant. In 2010 the turnover decreases due to the lack of ethylene – the main raw material used in the production process.

2013

Oltchim goes into insolvency;

2018

In December 2018, Mr. Ștefan Vuza managed, by contracting an international loan of 1 64 million euros, to acquire Oltchim’s Rm. Vâlcea assets. He thus saved this plant from bankruptcy on the last hundred meters. The financial transaction was spectacular, Mr. Vuza managed to convince a consortium of banks to finance it, although Chimcomplex had an annual turnover of 50 million euros, with a normal profit rate in the chemistry of 10% and a profit of 5 million euros per year. By acquiring these assets, Chimcomplex has strengthened its position as a producer and supplier of chemicals in Europe and formed the nucleus of the new chemical plant in Romania, around which 10 companies are currently gravitating.

2019-2020

Chimcomplex achieved all its goals, including financial ones, but the path was very different from how it was planned. The company had taken decisive actions and had shown a lot of resilience during COVID-19. At the same time, we encouraged employees, focusing on customer needs and supporting its communities. Chimcomplex closed the year with a stronger balance sheet, ready to accelerate its strategy and realize bold plans for the future.

2021

Chimcomplex stocks recorded the largest increase in history with 1.200% in 2021. It was the biggest increase on all European stock exchanges. Turnover doubled. Net profit increased by over 510% in 2021 compared to 2020. The financial results obtained as a reaction of the synergies between the two plants in Onești and Rm. Vâlcea provided additional liquidity that Chimcomplex

used to make investments and repay all bank loans in advance.

Chimcomplex acquired part of the assets of CET Govora with the idea of building a production capacity of thermal agents in a cogeneration plant. The Romanian Chemical Company has grown and has been reorganised into 8 divisions, to develop efficiently. Thus we have The Chemical Division, The Energy Division, The Research Division, The International Trade and Business Division, The Maintenance and Support Services Division, The Logistics and Transport Division, The Green Division and The White Division.

We also obtained accreditation for the Chimcomplex Academy – an authorized center for training, improvement, and development of competencies for attracting and maintaining staff.

The refinancing carried out in 2021 led to a 6-fold decrease in financial expenses and Chimcomplex achieved all its business objectives.

2022

Chimcomplex consolidated its service portfolio by acquiring Sistemplast S.A. Râmnicu Vâlcea, a company located on the Oltchim platform, that specialized in providing integrated solutions for mechanics, design, construction, verification and monitoring of industrial works.

After an investment of 40 million euros, Chimcomplex inaugurated a new polyol production plant. Thus, in Romania, almost 9% of the European production of polyols will be produced, which will bring the company to the 6th place among the top producers in Europe.

2023

At Rm. Vâlcea will be put into operation the largest high-efficiency cogeneration plant built in Romania, in the last 11 years. The three cogeneration groups have an annual energy capacity of 49.5 MWh, which is used on the platform. The cogeneration plant produces both electricity and thermal energy in the form of technological steam and hot water, with an overall efficiency of 90.5%. This investment of 40 million euros helps us eliminate our dependence on polluting alternatives, but also to reduce CO2 emissions by more than 88,000 tons/year, thus becoming a more responsible and sustainable company.

Chimcomplex is a consolidated company with growth potential and a market value of between 2 and 2.2 billion euros, considering both multiples of EBITDA in the chemical industry and the value on the stock market. Chimcomplex is today the largest producer of green hydrogen in Eastern Europe, with an annual production of over 6,000 tons. It is the only company in Europe’s 10 SE countries with real potential to use hydrogen as a raw material for green chemicals.

Currently, projects of over 55 million euros are in the final execution phase and projects worth over 125 million euros are being prepared and started.

Sign Up for Email Updates

Sign Up for Email Updates

Everchem Updates Archive

Everchem Updates Archive

Recent News

July 11, 2024

July 9, 2024

July 9, 2024