Urethane Blog

Chinese Propylene Oxide Production Process Forecast

July 9, 2018

Is the Chlorohydrination Process Declining?

2018-07-09 [Source:PUdaily]

share:

PUdaily, Shanghai– With the deepening of the environmental inspection campaign of revisiting the previously inspected provinces, which was launched in May, the first round of special “revisit” inspection is coming to an end. Plus the introduction of environmental tax at the beginning of the year, 2018 is a milestone year for the chemical industry when environmental rectification is carried out.

Although the inspection has not had significant negative impact on upstream PO production, the new Environmental Protection Comprehensive Directory (2017 Edition) classified PO as high-pollution products (except for PO produced by direct oxidation process). Today, PUdaily would like to talk about the challenges faced by chlorohydrination process and the corresponding possible solutions.

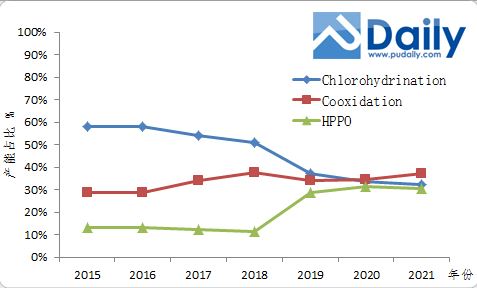

At present, the domestic PO facilities using chlorohydrination process account for 54% of the total PO production capacity. In the next few years, facilities using chlorohydrination process are expected to account for 33-37% of the total capacity (Fig. 1). From 2018 to 2021, more units using cooxidation process and direct oxidation proccess will be built. It is expected that four HPPO facilities and one or two PO/SM facilities will be built in 2019 alone. If all the units are put into production as planned, the additional capacity will amount to more than 1 million tons per year. This will undoubtedly have a great impact on PO producers using the traditional chlorohydrination process.

Fig.1 three PO production processes’ share of the total capacity over the next 3 years

Note: the forecast is based on the data collected by PUdaily

How to improve the process to solve pollution while maintaining the advantage of low cost is a problem faced by all PO producers adopting the chlorohydrination process.

As is known to all, the problem of “three wastes” is the main factor that makes the chlorohydrination process less competitive than the cooxidation process and the direct oxidation process. The large amounts of waste water, waste gas and waste residue make the chlorohydrination process an environmentally unfriendly process. However, thanks to the efforts of many PO manufacturers many new technologies and solutions emerge, providing new approaches to solve the problem.

1) Waste gas

The waste gases produced in the chlorohydrination process mainly include chlorohydrination tail gas and other tail gases (including tail gases produced in saponification, distillation and caustic washing systems). The main components of chlorohydrination tail gas are propane, propylene, oxygen, nitrogen and water. Of which oxygen has an amount of 40vol%, and propane and propylene has a combined amount of 20vol%. In order to avoid the safety hazards such as explosion caused by conventional oxidation treatment, the main treatment method in the industry is to mix the waste gas with a large amount of air and then pump them into the combustion furnace. In the combustion furnace, propylene and propane are combusted as fuels. The tail gases discharged from the furnace are mainly carbon dioxide and nitrogen, which completely meet the environmental standards in the testing.

Tail gases from other apparatus include propylene, propane, epoxy propane, dichloropropane, nitrogen, oxygen and water. All these tail gases will be pumped into the water scrubber after nitrogen blanketting. Propylene oxide and propylene dichloride dissolve in the water. Other water-insoluble gases are recovered for additional chlorohydrination. Propylene oxide dissolved in the water is recovered using the distillation column, thus increasing the output of the chemical. Other wastewater in which organics are dissolved is discharged into the sewage-treatment plant.

2) Waste water

45 tons of high-salinity wastewater are produced when producing 1 ton of propylene oxide. In China, this waste water is generally discharged into the wastewater treatment plant for treatment. However, the problem of high salinity (the content of calcium chloride is 4%) in the waste water has drawn the attention of domestic environmental authorities. For example, Shandong Department of Environmental Protection has proposed a technical specification aiming at restricting the discharge of high-salinity wastewater into inland rivers. In response, some enterprises discharge such waste water into the sea after it is treated to meet the standards. It is reported that desired results are achieved.

3) Waste residue

For 1 ton of propylene oxide produced, 1.2-2.0 m³ of saponification waste residue will be produced. The waste residue, fly ash and attle can be used as raw materials to make standard bricks for building use, whose quality is even better than that of clay bricks. Presently, the production of solid clay bricks has been banned because of its heavy consumption of land resources. It is expected that there is a broad market for the bricks made using waste residue. In addition, the waste residue will probably be widely used in construction, roads building and other fields.

Here, we would like to express our gratitude to all the researchers who are devoted to studying the problem of “three wastes” produced in chlorohydrination process. It is their sustained efforts that have made it possible to improve this process.

At the same time, PUdaily holds that although the more environmental-friendly cooxidation process and direct oxidation proccess are the trend, considering the many limiting factors, the chlorohydrination process will not be eliminated in the short term. Manufacturers adopting this process should not stop their efforts in research and innovation, but actively solve the problems of safety and “three wastes”. But it must be admitted that the additional costs incurred may make the advantage of low price disappear. PUdaily will keep an eye on the developments of PO production processes. Also, we hope the researchers will make further progress in improving the chlorohydrination process, ensuring environmental protection and costs controlling.

http://www.pudaily.com/News/NewsView.aspx?nid=72590

Sign Up for Email Updates

Sign Up for Email Updates

Everchem Updates Archive

Everchem Updates Archive

Recent News

April 24, 2024

April 24, 2024

April 18, 2024

April 18, 2024

April 17, 2024