Epoxy

May 17, 2021

Port of LA is Busy

Port Of LA Volumes Are “Off The Charts”

by Tyler DurdenMonday, May 17, 2021 – 06:10 PM

By Kim Link-Wills of Freight Waves,

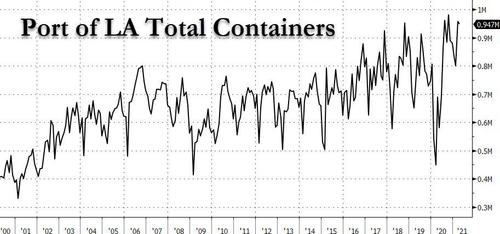

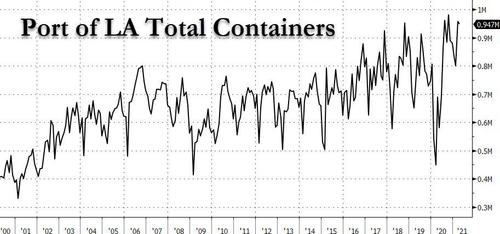

The Port of Los Angeles continued its record-setting streak, posting the busiest April in its 114-year history.

“It’s truly been an unprecedented run here in LA,” Executive Director Gene Seroka said during a media briefing Thursday.

The Port of LA handled 946,966 twenty-foot equivalent units (TEUs) in April. “That’s a 37% spike compared to last year, when global trade dropped with the onset of the pandemic,” Seroka said. “This was by far the busiest April in the port’s 114-year history, outpacing the previous record set just back in 2019 by a hefty 29%.”

He said the port has recorded nine consecutive months of year-over-year volume increases following 11 straight months of declines. “Remarkably, we have continued to average 900,000 TEUs per month dating all the way back to last July.”

The port handled 89 container ships last month, up from 76 in April 2020. And those vessels are being handled efficiently, Seroka said. “We averaged 16 container vessels per day at berth last month. Please remember, before the surge our average was only about 10.”

Port congestion also has eased, according to Seroka.

“We’ve seen as few as 13 container vessels at anchor in the San Pedro Bay over recent days,” he said, noting there were 17 ships at anchor, with eight of them bound for the Port of LA, as of late morning Thursday.

“Another encouraging sign: Fewer ships are going straight to the holding area. We’ve dropped from 90% in February to 65% of vessels heading straight to anchor in the month of April. Average wait time is now 6.7 days after peaking out at 7.9 days in March,” Seroka said.

He noted that nine vessels were at anchor on April 30, representing an additional 132,000 TEUs that will be included in the May numbers.

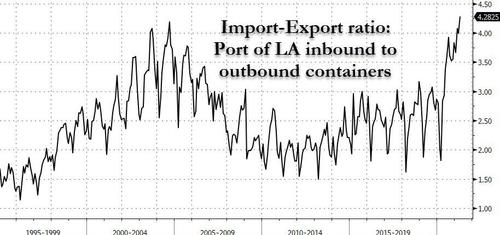

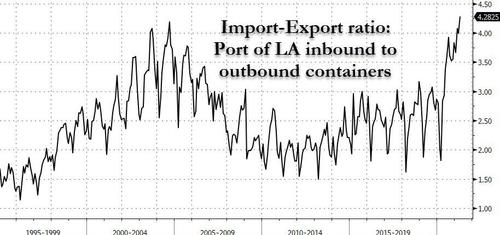

Although congestion has eased, imports haven’t let up, Seroka said, reporting April import volume totaled 490,127 TEUs, a 32.4% year-over-year increase.

“Exports, however, continue to drag, with less than 115,000 TEUs on that side of the ledger, down 12%. Exports have now dropped 27 of the last 30 months here at Los Angeles,” he said.

“April’s import-export ratio was almost 4.3-to-1, which unfortunately is the highest gap we’ve seen yet,” Seroka said. “And the scramble for empties continues, with over 342,000 empty container units repositioned back to Asia in April. That’s just a few thousand TEUs shy of last month’s all-time record” and an 81.6% increase from April 2020.

The figures for the first four months of 2021 are “off the charts,” he said. “We handled more than 3.5 million TEUs, a 42% increase compared to 2020.”

Seroka noted that total volume from Jan. 1 to April 30 was up 20% compared to the same period in “less-volatile” 2019.

https://www.zerohedge.com/markets/port-la-volumes-are-charts

May 17, 2021

Port of LA is Busy

Port Of LA Volumes Are “Off The Charts”

by Tyler DurdenMonday, May 17, 2021 – 06:10 PM

By Kim Link-Wills of Freight Waves,

The Port of Los Angeles continued its record-setting streak, posting the busiest April in its 114-year history.

“It’s truly been an unprecedented run here in LA,” Executive Director Gene Seroka said during a media briefing Thursday.

The Port of LA handled 946,966 twenty-foot equivalent units (TEUs) in April. “That’s a 37% spike compared to last year, when global trade dropped with the onset of the pandemic,” Seroka said. “This was by far the busiest April in the port’s 114-year history, outpacing the previous record set just back in 2019 by a hefty 29%.”

He said the port has recorded nine consecutive months of year-over-year volume increases following 11 straight months of declines. “Remarkably, we have continued to average 900,000 TEUs per month dating all the way back to last July.”

The port handled 89 container ships last month, up from 76 in April 2020. And those vessels are being handled efficiently, Seroka said. “We averaged 16 container vessels per day at berth last month. Please remember, before the surge our average was only about 10.”

Port congestion also has eased, according to Seroka.

“We’ve seen as few as 13 container vessels at anchor in the San Pedro Bay over recent days,” he said, noting there were 17 ships at anchor, with eight of them bound for the Port of LA, as of late morning Thursday.

“Another encouraging sign: Fewer ships are going straight to the holding area. We’ve dropped from 90% in February to 65% of vessels heading straight to anchor in the month of April. Average wait time is now 6.7 days after peaking out at 7.9 days in March,” Seroka said.

He noted that nine vessels were at anchor on April 30, representing an additional 132,000 TEUs that will be included in the May numbers.

Although congestion has eased, imports haven’t let up, Seroka said, reporting April import volume totaled 490,127 TEUs, a 32.4% year-over-year increase.

“Exports, however, continue to drag, with less than 115,000 TEUs on that side of the ledger, down 12%. Exports have now dropped 27 of the last 30 months here at Los Angeles,” he said.

“April’s import-export ratio was almost 4.3-to-1, which unfortunately is the highest gap we’ve seen yet,” Seroka said. “And the scramble for empties continues, with over 342,000 empty container units repositioned back to Asia in April. That’s just a few thousand TEUs shy of last month’s all-time record” and an 81.6% increase from April 2020.

The figures for the first four months of 2021 are “off the charts,” he said. “We handled more than 3.5 million TEUs, a 42% increase compared to 2020.”

Seroka noted that total volume from Jan. 1 to April 30 was up 20% compared to the same period in “less-volatile” 2019.

https://www.zerohedge.com/markets/port-la-volumes-are-charts

May 17, 2021

Wind Turbine Blade Recycling Project

Home/Environment/New Technology for Full Recyclability of Wind Turbine Blades Environment

New Technology for Full Recyclability of Wind Turbine Blades

Energy Industry Review4 hours agoLast Updated: May 17, 2021 30 4 minutes read

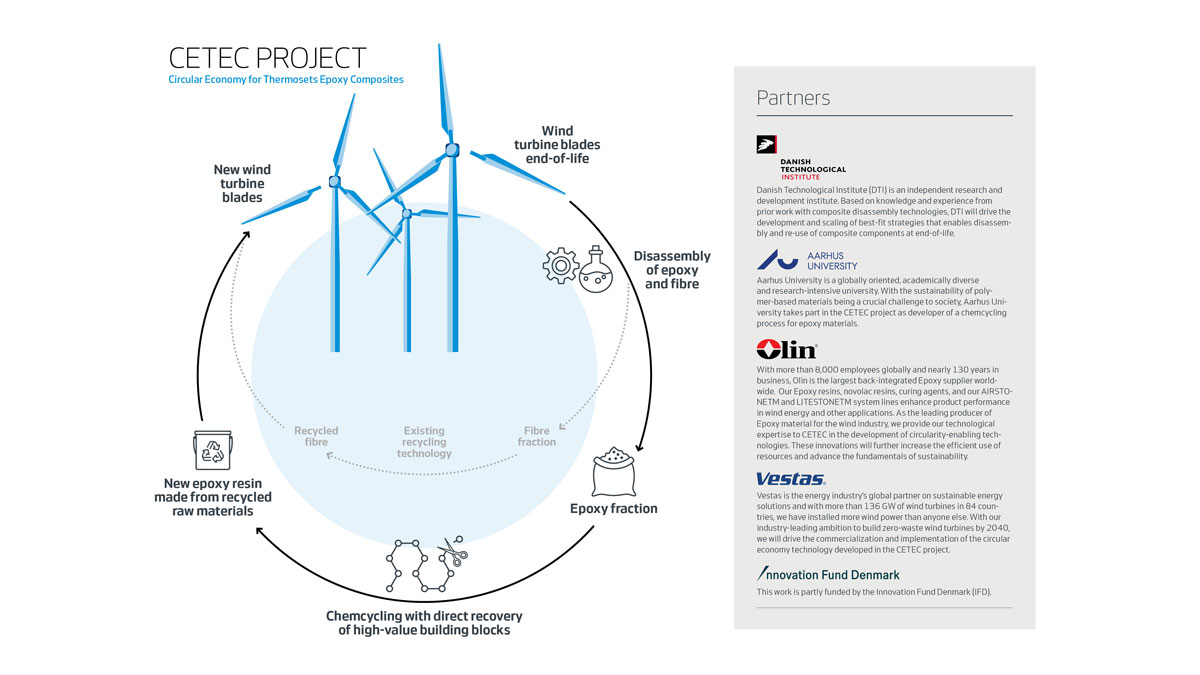

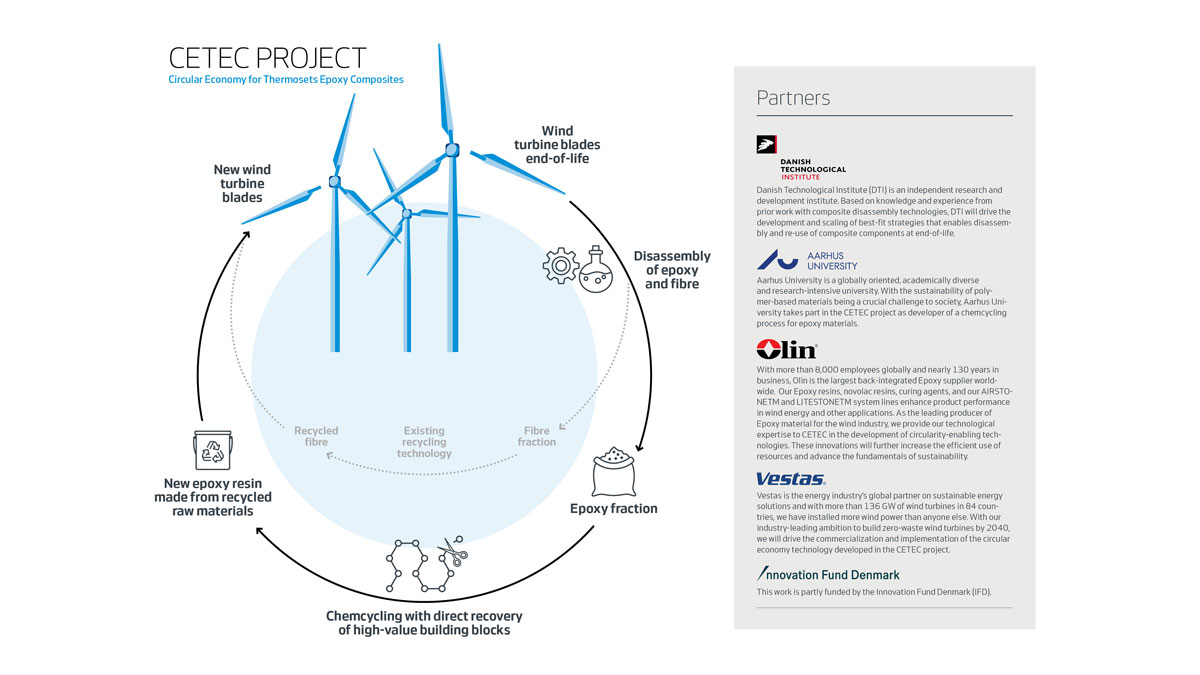

A coalition of industry and academic leaders have developed a new technology to enable circularity for thermoset composites, the material used to make wind turbine blades. The new technology delivers the final technological step on the journey towards a fully recyclable wind turbine value chain. To enable the adoption of this new technology, and to advance a circular economy across the wind industry, a new initiative entitled CETEC (Circular Economy for Thermosets Epoxy Composites) has been established. Within three years, CETEC is aiming to present a fully scoped solution ready for industrial adoption, based on commercialisation of the novel circularity technology.

Partly funded by Innovation Fund Denmark (IFD), CETEC is spearheaded by Vestas, the global leader in sustainable energy solutions, and involves both industrial and academic leaders including Olin, the world leading producer of Epoxy, the Danish Technological Institute (DTI), and Aarhus University.

Developed by DreamWind, an innovation initiative driven by the same partners, the new technology consists of a two-step process. Firstly, thermoset composites are disassembled into fibre and epoxy. Secondly, through a novel chemcycling process, the epoxy is further broken up into base components similar to virgin materials. These materials can then be reintroduced into the manufacturing of new turbine blades, constituting a new circularity pathway for epoxy resin.

Wind turbines are 85-90 percent recyclable, with turbine blades material constituting the remaining percentage that cannot be recycled, due to the nature of thermoset composites. CETEC is aiming to close this recycling gap and enable a significant step forward in the elimination of waste across the wind energy industry.

“As global commitments to a net-zero future increase, it’s absolutely crucial to ensure the wind industry can scale sustainably, which includes Vestas fulfilling our ambition to produce zero-waste turbines by 2040. Leveraging this new technological breakthrough in chemcycling epoxy resin, the CETEC project will be a significant milestone in Vestas’ journey towards achieving this goal, and in enabling a future where landfill is no longer required in blade decommissioning,” said Allan Korsgaard Poulsen, Head of Sustainability and Advanced Materials, Vestas Innovation and Concepts.

“The key characteristic of composite materials is their unique combination of low weight and high strength. This is governed by the strong bonding of two different materials – fibre and epoxy. The dilemma is that this strong bond is also the feature that renders these materials difficult to recycle. Therefore, the development of CETEC’s novel technology, enabling disassembly of the composite at end-of-life, is a gamechanger, that will allow us to capture the value represented by each material stream in a new circular value chain”, said Simon Frølich, Team Manager, PhD, Danish Technological Institute.

“Chemcycling of epoxy-based materials would allow deconstructing these highly stable polymer chains into molecular building blocks. These building blocks are easily processable and can be utilised to produce new epoxy, which will have the same quality as the original material. Avoiding the loss of valuable molecular complexity in such a way is a highly desirable concept and an important step to sustainable materials,” said Prof. Dr. Troels Skrydstrup, Aarhus University.

CETEC’s solution will address the lack of available recycling technology for epoxy resins. This would in turn create the possibility to introduce new recycling solutions to the wind industry. This holds significant potential for commercial value capture, particularly in markets where regulation around waste management for manufacturing industries is tightening to serve a broader sustainability agenda. When fully developed, the solution may also have an impact for other industries that rely on thermoset composite in production, such as automotive and aviation.

“As the leading Epoxy producer and global supplier for the wind industry, Olin is proud to provide our technological expertise to this important sustainability project,” said Leif Ole Meyer, TS&D Leader EMEAI at Olin. “To develop technologies which close an existing gap of thermosets by creating a circularity is yet another example of putting our Resource Efficiency sustainability goal into action. This innovation will help the industry to minimize consumption of virgin material sources and increase the reuse and recycling of materials.”

About Danish Technological Institute

Danish Technological Institute (DTI) is an independent research and development institute. It takes an innovative approach to improving the competitiveness of business and industry, society and public life. With more than 12,000 customers in 65 countries, they develop new knowledge through research and development activities in close corporation with Danish and international companies and research institutes.

About Aarhus University

Aarhus University is a globally oriented, academically diverse, and research-intensive university. Aarhus University ranks among the top 100 universities in the world on several of the most important international ranking lists, out of over 17,000 universities worldwide. Around 12 per cent of AU’s 40.000 students are international, representing over 120 nationalities. Aarhus University offers state-of-the-art facilities and laboratories having a strong tradition of multidisciplinary research for instance in one of its 42 major research centres. The university’s goal is to contribute towards solving the complex global challenges facing the world. The university therefore strives to combine the high level of academic standards of its researchers with collaboration across disciplinary boundaries to combine research in new ways and solve challenges in close contact with the world around us.

About Olin

With over 8,000 employees globally and almost 130 years in business, Olin Corporation is the world’s chlor-alkali leader, including epoxy products and chlorinated organics. Olin’s regional headquarters for Europe, Middle East, Africa, and India is based in Zug, Switzerland. The company employs over 650 professionals in its European offices, research, and innovation centres, and manufacturing locations in Baltringen, Rheinmunster and Stade, Germany, Pisticci, Italy, and Terneuzen, Netherlands. Olin is committed to exceeding customer expectations through operational and commercial excellence, innovation capabilities and quality people who serve their valued customers.

About Vestas

Vestas is the energy industry’s global partner on sustainable energy solutions. They design, manufacture, install, and service onshore and offshore wind turbines across the globe, and with more than 136 GW of wind turbines in 84 countries, Vestas has installed more wind power than anyone else. Through its industry-leading smart data capabilities and unparalleled more than 117 GW of wind turbines under service, Vestas uses data to interpret, forecast, and exploit wind resources and deliver best-in-class wind power solutions. Together with their customers, Vestas’ more than 29,000 employees are bringing the world sustainable energy solutions to power a bright future.

May 17, 2021

Wind Turbine Blade Recycling Project

Home/Environment/New Technology for Full Recyclability of Wind Turbine Blades Environment

New Technology for Full Recyclability of Wind Turbine Blades

Energy Industry Review4 hours agoLast Updated: May 17, 2021 30 4 minutes read

A coalition of industry and academic leaders have developed a new technology to enable circularity for thermoset composites, the material used to make wind turbine blades. The new technology delivers the final technological step on the journey towards a fully recyclable wind turbine value chain. To enable the adoption of this new technology, and to advance a circular economy across the wind industry, a new initiative entitled CETEC (Circular Economy for Thermosets Epoxy Composites) has been established. Within three years, CETEC is aiming to present a fully scoped solution ready for industrial adoption, based on commercialisation of the novel circularity technology.

Partly funded by Innovation Fund Denmark (IFD), CETEC is spearheaded by Vestas, the global leader in sustainable energy solutions, and involves both industrial and academic leaders including Olin, the world leading producer of Epoxy, the Danish Technological Institute (DTI), and Aarhus University.

Developed by DreamWind, an innovation initiative driven by the same partners, the new technology consists of a two-step process. Firstly, thermoset composites are disassembled into fibre and epoxy. Secondly, through a novel chemcycling process, the epoxy is further broken up into base components similar to virgin materials. These materials can then be reintroduced into the manufacturing of new turbine blades, constituting a new circularity pathway for epoxy resin.

Wind turbines are 85-90 percent recyclable, with turbine blades material constituting the remaining percentage that cannot be recycled, due to the nature of thermoset composites. CETEC is aiming to close this recycling gap and enable a significant step forward in the elimination of waste across the wind energy industry.

“As global commitments to a net-zero future increase, it’s absolutely crucial to ensure the wind industry can scale sustainably, which includes Vestas fulfilling our ambition to produce zero-waste turbines by 2040. Leveraging this new technological breakthrough in chemcycling epoxy resin, the CETEC project will be a significant milestone in Vestas’ journey towards achieving this goal, and in enabling a future where landfill is no longer required in blade decommissioning,” said Allan Korsgaard Poulsen, Head of Sustainability and Advanced Materials, Vestas Innovation and Concepts.

“The key characteristic of composite materials is their unique combination of low weight and high strength. This is governed by the strong bonding of two different materials – fibre and epoxy. The dilemma is that this strong bond is also the feature that renders these materials difficult to recycle. Therefore, the development of CETEC’s novel technology, enabling disassembly of the composite at end-of-life, is a gamechanger, that will allow us to capture the value represented by each material stream in a new circular value chain”, said Simon Frølich, Team Manager, PhD, Danish Technological Institute.

“Chemcycling of epoxy-based materials would allow deconstructing these highly stable polymer chains into molecular building blocks. These building blocks are easily processable and can be utilised to produce new epoxy, which will have the same quality as the original material. Avoiding the loss of valuable molecular complexity in such a way is a highly desirable concept and an important step to sustainable materials,” said Prof. Dr. Troels Skrydstrup, Aarhus University.

CETEC’s solution will address the lack of available recycling technology for epoxy resins. This would in turn create the possibility to introduce new recycling solutions to the wind industry. This holds significant potential for commercial value capture, particularly in markets where regulation around waste management for manufacturing industries is tightening to serve a broader sustainability agenda. When fully developed, the solution may also have an impact for other industries that rely on thermoset composite in production, such as automotive and aviation.

“As the leading Epoxy producer and global supplier for the wind industry, Olin is proud to provide our technological expertise to this important sustainability project,” said Leif Ole Meyer, TS&D Leader EMEAI at Olin. “To develop technologies which close an existing gap of thermosets by creating a circularity is yet another example of putting our Resource Efficiency sustainability goal into action. This innovation will help the industry to minimize consumption of virgin material sources and increase the reuse and recycling of materials.”

About Danish Technological Institute

Danish Technological Institute (DTI) is an independent research and development institute. It takes an innovative approach to improving the competitiveness of business and industry, society and public life. With more than 12,000 customers in 65 countries, they develop new knowledge through research and development activities in close corporation with Danish and international companies and research institutes.

About Aarhus University

Aarhus University is a globally oriented, academically diverse, and research-intensive university. Aarhus University ranks among the top 100 universities in the world on several of the most important international ranking lists, out of over 17,000 universities worldwide. Around 12 per cent of AU’s 40.000 students are international, representing over 120 nationalities. Aarhus University offers state-of-the-art facilities and laboratories having a strong tradition of multidisciplinary research for instance in one of its 42 major research centres. The university’s goal is to contribute towards solving the complex global challenges facing the world. The university therefore strives to combine the high level of academic standards of its researchers with collaboration across disciplinary boundaries to combine research in new ways and solve challenges in close contact with the world around us.

About Olin

With over 8,000 employees globally and almost 130 years in business, Olin Corporation is the world’s chlor-alkali leader, including epoxy products and chlorinated organics. Olin’s regional headquarters for Europe, Middle East, Africa, and India is based in Zug, Switzerland. The company employs over 650 professionals in its European offices, research, and innovation centres, and manufacturing locations in Baltringen, Rheinmunster and Stade, Germany, Pisticci, Italy, and Terneuzen, Netherlands. Olin is committed to exceeding customer expectations through operational and commercial excellence, innovation capabilities and quality people who serve their valued customers.

About Vestas

Vestas is the energy industry’s global partner on sustainable energy solutions. They design, manufacture, install, and service onshore and offshore wind turbines across the globe, and with more than 136 GW of wind turbines in 84 countries, Vestas has installed more wind power than anyone else. Through its industry-leading smart data capabilities and unparalleled more than 117 GW of wind turbines under service, Vestas uses data to interpret, forecast, and exploit wind resources and deliver best-in-class wind power solutions. Together with their customers, Vestas’ more than 29,000 employees are bringing the world sustainable energy solutions to power a bright future.

May 15, 2021

Brenntag Hit By Darkside

Darkside Retreats to the Dark

After announcing that its criminal infrastructure has been taken down due to U.S. law enforcement pressure, the Darkside ransomware gang says it’s retreating. But is it?

| Kim Zetter | 4 hr ago |

The Darkside gang began last Friday with a bang; but they may be ending their operations a week later with a whimper. Or they may be pulling another scam — this time to cheat affiliates out of their share of the ransom take.

After pulling in at least $9 million from two victims — $5 million paid by Colonial Pipeline on May 8 and about $4.4 million paid by the chemical distribution company Brenntag on May 11 — the developers behind the Darkside ransomware went offline.

Their dark web site — previously accessible only through the Tor browser — became unavailable on Thursday, and someone from a rival ransomware gang posted a message to a forum that was purportedly from the developer of the Darkside ransomware code. The message said the Darkside founders had lost access to the site where they hosted and published data stolen from ransomware victims who refused to pay, and they also lost access to the payment server and other infrastructure they need to collect payment and run their operations.

“A few hours ago, we lost access to the public part of our infrastructure, namely : Blog, Payment server, DOS servers,” reads a since-deleted message from a user called Darksupp, according to The Record, a publication of Recorded Future. The service provider that hosted the infrastructure told the Darkside operators that the sites and servers were taken down “at the request of law enfocement [sic] agencies.” Darksupp also said that cryptocurrency had been withdraw from the wallet they used to store payments from ransomware victims.

There’s reason to believe that at least some of this is true. Reuters and Bloomberg reported earlier this week that companies assisting Colonial Pipeline in their response to the incident worked with the FBI to get a hosting provider in New York to shut down a server that was storing data stolen from Colonial Pipeline before the thieves could transfer it to Russia, where the perpetrators are believed to be based.

And on Friday, Elliptic, a blockchain analytics company which also makes compliance tools for cryptocurrency businesses to monitor transactions, reported that it had identified the Bitcoin wallet used by the Darkside gang. The company said that on Thursday, the wallet — which still held $5 million in Bitcoin — was emptied.

Some have suggested this could be a ruse on the part of the Darkside gang to avoid sharing ransom proceeds with their affiliates who carried out the ransomware operation against Colonial Pipeline. Without knowing where the funds went, however, it’s difficult to know if the FBI seized it or if the Darkside gang emptied the wallet themselves.

The wallet, according to Elliptic, became active on March 4th and received 57 payments from 21 other Bitcoin wallets, totalling $17.5 million.

“Some of these payments directly match ransoms known to have been paid to DarkSide by other victims, such as 78.29 BTC (worth $4.4 million) sent by chemical distribution company Brenntag on May 11,” the company noted.

If authorities did seize $5 million in Bitcoin that was still sitting in the Darkside wallet, it’s only a fraction of what the criminal syndicate had already laundered out of the wallet since March.

According to Elliptic, about 18% of the wallet’s contents was sent to a small group of cryptocurrency exchanges, where Bitcoin is traded among buyers and sellers. “This information will provide law enforcement with critical leads to identify the perpetrators of these attacks,” the company noted. “An additional 4% has been sent to Hydra, the world’s largest darknet marketplace, servicing customers in Russia and neighboring countries.”

Hydra allows users to cash out their Bitcoin by converting it to cash or loading sums onto prepaid debit or gift cards.

In addition to Darkside’s retreat, another top ransomware group known as REvil has announced that it plans to stop advertising its ransomware service and instead “go private” by working with only a small group of trusted affiliates, The Record reported.

Some are cautioning that the moves by Darkside and REvil don’t mean their activity will stop; just that the operators plan to become less flashy in order to attract less law enforcement attention.

“I sincerely hope the Infosec community and media don’t lose their minds over thinking DarkSide is actually shutting down when it’s almost certainly a rebranding attempt to avoid the heat,” Robert M. Lee, CEO of the security firm Dragos wrote on Twitter on Friday.