The Urethane Blog

Everchem Updates

VOLUME XXI

September 14, 2023

Everchem’s exclusive Closers Only Club is reserved for only the highest caliber brass-baller salesmen in the chemical industry. Watch the hype video and be introduced to the top of the league: — read more

November 28, 2023

Wanhua Chemical : Converging Passion, Moving Forward Together – A Letter of Gratitude from Chairman to All Wanhua Staff

November 28, 2023 at 10:07 am

Share

Converging Passion, Moving Forward Together – A Letter of Gratitude from Chairman to All Wanhua Staff

TIME :2023-11-28

Dear Colleagues,

As sure as day turns to night, another year has flown by, bringing us back to our annual day of gratitude at Wanhua. On this meaningful day, I want to extend my sincere regards to all our teammates, the families of Wanhua teammates, and our friends from every corner who’ve had our back – a massive thank you! We’re truly grateful for your understanding, support, trust, and belief in us.

The year 2023 holds exceptional significance. We’ve seen the international order was going through some real roller coaster changes. As we came out of the pandemic, the global economy is picking itself up, dusting off, and moving forward amidst challenges and opportunities. In this game-changing time, every one of us at Wanhua has pulled together, bringing our surging momentum, and fueling our drive for high-quality development.

Thank you for your contributions that have brought success to Wanhua. Our front-line production crew has been great like never before, fine-tuning our lean manufacturing process. Your dedication to excellence makes our products the go-to choice for customers. Our marketing team has been nailing it with the “broadening sales channels, cooperating in a win-win relationship” approach, continuously delivering value to our customers with standout products and services, and beefing up Wanhua’s global reach. The procurement team, focusing on business needs, has been sticking to the rules and making progress in securing feedstock supply, supplier diversification, and equipment localization. You all have played a part in Wanhua’s success story, winning rave reviews from customers with our stellar products.

A round of applause for sparking Wanhua’s innovation. With continuous innovation, our R&D folks have brought to reality our seventh-gen MDI manufacturing tech, pushing the boundaries of the polyurethane industry and leading a wave globally. You’re driving us towards greater efficiency, better quality, and lower energy consumption. Seizing the opportunities, you’ve made breakthroughs in advanced materials, helping Wanhua’s high-quality development and standing on the cutting edge with world-class products and technology, with your innovative spirit. In an era of ‘innovation inside the box,’ creating an environment where innovation isn’t just encouraged but a norm. Your collective efforts are the fuel that’s propelling Wanhua forward.

Thanks for mapping out Wanhua’s journey. You’ve been trailblazers, across continents, leaving a mark of Wanhua’s diligence everywhere. Our Penglai low-carbon industrial park is rising with the construction of mega ethylene project phase II, not to mention Fujian TDI, Ningxia MDI, Ningbo HDI phase II, and Meishan NMP started operation. You’re painting a picture of Wanhua’s growth day by day, pushing us towards greater heights.

I feel thankful to every unsung hero at Wanhua, for your tireless work and contributions, as even a bit of effort counts and deserves a salute. The sweat, and tears on this journey, the heroes who’ve stepped up when it is the time, and the incredible achievements we’ve accomplished together, have merged into an unstoppable force, moving us confidently towards an extraordinary future of Wanhua.

While the prospects are bright, the road has twists and turns. We’ve ridden the waves of a momentous journey and are now gearing up for even more remarkable glory! Fellow teammates, let’s carry the spirit of gratitude, our grand mission, and our heartfelt passion, and unite as one for exponential growth. Let’s aim to build a world-class enterprise, a legacy that will last for centuries, and write a dazzling story!

A heartfelt gratitude to every one of Wanhua for your unwavering dedication!

Liao Zengtai

November 23, 2023

November 22, 2023

Wanhua Chemical : Launched NMP Material Solutions

November 22, 2023 at 07:18 am

Wanhua Chemical Launched NMP Material Solutions

TIME :2023-11-22

Recently, methylamine facility of Wanhua started production successfully in one shot. It initials from natural gas, through acetylene, then BDO, GBL, methylamine and finally NMP, with an annual capacity of 80kT which is the single largest line in the world. The establishment of this plant is a firm step of Wanhua’s ambition on battery industry.

High-Quality Product:

N-Mthylpyrrolidone (NMP) is an organic solvent used in a variety of industries and applications. For example, anode paste, conductive paste, photoresist, screen cleaner, and as solvent for a series of polymer synthesis like aramid, polyphenylene sulfide(PPS), polyimide(PI). Besides, it can also be seen in insulation coating and some other pharma and petrochemical applications.

When it comes to battery field, the purity, chroma, and free amine are among the key parameters that customers are concerned about. Through innovation and continuous optimization on process and high precision test, Wanhua established comprehensive quality control system resulted a more than 99.9% purity.

Industrial Chain Advantage:

Leveraging Sichuan production base that is deeply integrated and power by green electricity, plus its natural gas supply advantage, the supply chain is secured with consistency.

In the future, Wanhua Chemical will promote the development of li-ion battery industry with the advantages of R&D capability, supply chain competitiveness and industrial park integration. We will participate and build a sustainable battery ecosystem.

November 21, 2023

China’s PU Market Experienced Sluggishness in October

PUdaily | Updated: November 16, 2023

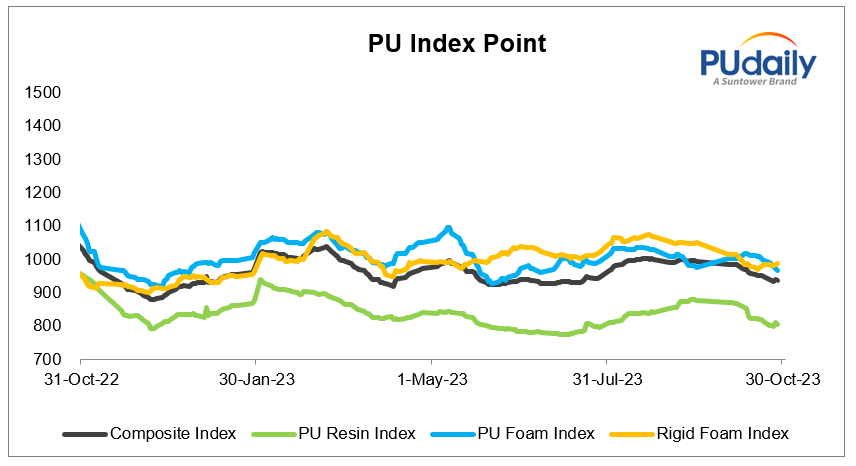

The PU composite index for October fluctuated. September saw a weaker-than-expected PU market. in October, the market became even more sluggish.Amid few inquiries, trading in PU raw materials was thin, resulting in a consolidating PU market.

The flexible PU foam index declined in October Earlier this month, spot TDI supply was tight as Wanhua(Xinjiang), Wanhua(Fujian) and Gansu Yinguang Chemical Industry shut their plants.In addition, some manufacturers needed to fulfill orders placed in September, and Covestro (Shanghai) stopped selling to boost the market. As a result, the TDI market rose significantly. Later, however, as demand became weak and spot supply increased with facilities restarted, manufacturers had to reduce prices to facilitate sale, resulting in a sharp fall in the TDI market. Flexible slabstock polyols manufacturers discussed prices with buyers.

In October, the rigid PU foam index consolidated at a low level. In the month, demand for rigid PU foam was sluggish.Specifically, demand from refrigerator manufacturers continued to rise, thanks to the double-digit year-on-year growth in refrigerator exports; that from insulated pipeline project in North China shrank; and that from the cold chain and OCF sectors remained weak. Late this month, due to tight MDI supply, the market bottomed out. With ample supply and finding it hard to sell, rigid polyols manufacturers discussed prices with buyers.

The resin index remained low in October. In the month, the AA market dipped. The high costs lent some support, but demand was sluggish as buyers made purchases as needed. The BDO market was down. In the month, the prices of feedstocks calcium carbide and methanol fell, lending decreased support to the BDO market. The supply rose significantly as maintenance was completed. However, demand was sluggish. Due to cost pressure, manufacturers were loath to reduce prices and decreased supply. but this provided limited support. traders were keen to sell. The THF market was soft-to-stable in October. The industry operating rate decreased, while operating rates in downstream sectors increased. traders sold goods according to market conditions. The PTMEG market remained stable in October. The operating rates in spandex industry remained stable, but the inventory cycle was extended. In the non-spandex products industry, synthetic leather resin manufacturers kept their operating rates low and made purchases as needed.

November 20, 2023

Hennecke Inc. looks back on a remarkable Open

House event

Hennecke Inc, the U.S. headquarters of the global Hennecke

GROUP, hosted a highly successful Open House event with

more than 100 visitors from across the country in October. The

event focused on innovation and customer-driven solutions in

polyurethane processing as well as a commitment to a

sustainable future. Customers and partners were offered a

unique opportunity to learn first-hand how Hennecke’s diverse

innovations can drive the success of their own businesses.

The successful Open House was a testament to Hennecke’s North American

subsidiary’s customer-centric approach and commitment to helping them

succeed with customized solutions. “We remain focused on our mission to

provide best-in-class solutions and lead the way in innovation and customer

satisfaction,” said Lutz Heidrich, president of Hennecke’s North American

business unit. “Our success and progress would not be possible without the

partnership and trust of our customers. We are committed to help companies

succeed with our solutions,” added Heidrich.

During the Open House, visitors had the opportunity to learn about various

innovative solutions such as the NEXT-GEN high-pressure metering

machines that offer a wide range of applications to increase customer

efficiencies using digitalization and precision. Hennecke Inc. also offers

solutions that are specially adapted for the North American market such as

the new ECOPLUS MK2 which will be available with Allen-Bradley-based

automation in Q1 of 2024. Another highlight was Hennecke’s mixhead

technology of the MT-E and MT-A series. Visitors were able to explore the

mode of operation and specific advantages using AR technology. The NEXT-

GEN lineup was one of the largest development projects in Hennecke’s

history. Attendees were also able to see firsthand the performance scope of

the new HX pump generation.

In the field of systems technology, Hennecke Inc. is an innovation driver in

the field of tank farm solutions and raw material handling. Hennecke’s

specialists presented unique selling points and advantages and discussed

the profitability of large-scale production facilities using sample calculations.

In addition, the revolutionary FOAMWARE control system for slabstock and

molded foam lines was demonstrated. The attendees were informed about

the increasing importance of blowing agents in PU production and the latest

technological developments in this field. Attendees also had the opportunity

to see live demonstrations of innovative production technologies such as

laser cutting and 3-D printing, and virtual glasses used for assisting

customers remotely saving both time and money.

When it comes to absolute focus on the customer, however, the portfolio in

the field of machine and systems engineering is only part of the measures

that Hennecke Inc. combines under one roof. The modern company

headquarters also includes a customer trial laboratory, a mixhead and pump

repair and training area and a state-of-the-art spare parts warehouse which

utilizes a VLM to store over $2.5 million in inventory.

In addition to these innovations, the open house highlighted Hennecke’s

commitment to sustainability and the steps the company has taken to reduce

its own, as well as its customers’, carbon footprint to ensure a more

sustainable future for all. The customer feedback was very positive: “It was

great to meet the welcoming team of Hennecke Inc. at the Open House. The

machines on display and numerous presentations were impressive and very

informative. It was immediately clear to us that the event will prove very

useful for several current projects.” Says Vinnie Bonaddio of Rogers Foam

Cooperation in Somerville (MA).

www.hennecke.com

California reaches mattress recycling milestone

Since the launch of the Bye Bye Mattress campaign in California, the state has recycled 10 million mattresses.

Photo courtesy of the Mattress Recycling Council

Posted by Bob Gaetjens | November 14, 2023

More than 10 million mattresses have been recycled in California since the Mattress Recycling Council (MRC) launched the Bye Bye Mattress program in the state.

The organization, which has operations in several states, reached that milestone nationally in March 2022.

If laid end-to-end, that is enough mattresses to stretch from California’s coastline to the middle of the Indian Ocean. As a result, recyclers have diverted more than 380 million pounds of steel, foam, fiber and wood from landfills and made them available for use in new products such as carpet padding, construction rebar and mulch.

“By reducing the demand to use virgin materials in other products, mattress recycling is contributing to California’s other important environmental goals—saving water, conserving energy and preventing greenhouse gas (GHG) emissions,” MRC Chief Operating Officer Mike O’Donnell says. “We have the data to prove it too. A recent analysis of our California program’s environmental footprint from collection to recycling shows that each mattress recycled saves 500 gallons of water, conserves enough energy to power a house for three days and reduces greenhouse gas emissions equivalent to driving 60 fewer miles.”

MRC’s Bye Bye Mattress is a statewide network of collection sites and events serving urban and rural communities across California that is made possible through collaborations with solid waste providers and nonprofit organizations. A growing number of waste haulers collecting bulky items at the curb are also recycling mattresses through the program.

Mattresses are transported from participating collection locations to regional recyclers, where they are dismantled into their different component parts. Mattress retailers, hotels, dormitories, nursing homes, military bases and other types of businesses also are working with MRC to have their old mattresses collected and recycled by the program.

“We are proud of what we have accomplished in California, but we know there are opportunities for the program to innovate and evolve,” O’Donnell says. “This is why we are supporting the industry’s broader efforts to encourage circular design and sustainability initiatives.”

The MRC undertakes research to improve collection, transportation and recycling processes. This includes providing research firms and educational institutions up to $100,000 in funding for projects aimed at discovering new uses for mattress materials. To date, MRC has awarded funds to more than 30 projects and is seeing some promising outcomes.

“One day, recycled mattress materials may help [electric vehicle] batteries hold longer charges or be used to make shoe soles or clean up oil spills,” O’Donnell says. “We need innovators to create new uses for polyurethane foam, quilt panels, cotton and mixed fibers.”

In addition to Bye Bye Mattress, MRC’s other California activities include offering mattress manufacturing facilities in the state an environmental certification program known as the Sleep Products Sustainability Program (SP2), which encourages conservation and resource efficiency.

“All these accomplishments are possible because MRC has the support of the mattress industry, mattress retailers, the solid waste industry and state agencies that provide oversight and guidance for our programs,” O’Donnell says. “We are also grateful to the international community of mattress recyclers and product stewardship organizations for sharing their best practices, collaborating on research projects and their commitment to sustainability.”

The MRC is an Alexandria, Virginia-based nonprofit organization that operates recycling programs in states that have passed mattress recycling laws, including California, Connecticut and Rhode Island. MRC was founded by the bedding industry and recycles nearly 2 million mattresses each year.

https://www.recyclingtoday.com/news/mattress-recycling-council-bye-bye-california-milestone/