The Urethane Blog

Everchem Updates

VOLUME XXI

September 14, 2023

Everchem’s exclusive Closers Only Club is reserved for only the highest caliber brass-baller salesmen in the chemical industry. Watch the hype video and be introduced to the top of the league: — read more

September 3, 2020

Power outages after hurricane lead to FMs on one third of US MEG capacity

Author: Antoinette Smith

2020/09/01

HOUSTON (ICIS)–Following Hurricane Laura, more than one third of US monoethylene glycol (MEG) production capacity is included in force majeure declarations.

Three producers in southwestern Louisiana and southeastern Texas – Lotte, Indorama and Sasol – declared force majeure as a result of the category 4 storm, which hit the area early morning on 27 August.

These three plants represent 35% of US MEG capacity, according to the ICIS Supply and Demand Database.

Power outages remain in the US as a result of Hurricane Laura, preventing some chemical companies from restarting their plants.

US MEG supply was already tight, ahead of a heavy slate of planned maintenance.

Click here to view the US Gulf storms – impacts on chemicals topic page.

MEG is an intermediate in the production of polyester fibres and polyethylene terephthalate (PET) bottle resins, and as an automotive antifreeze.

Major glycol producers in the US include Eastman Chemical, Indorama Ventures, Lotte Chemical, LyondellBasell, MEGlobal, Nan Ya Plastics, Sasol and Shell Chemical.

September 3, 2020

Power outages after hurricane lead to FMs on one third of US MEG capacity

Author: Antoinette Smith

2020/09/01

HOUSTON (ICIS)–Following Hurricane Laura, more than one third of US monoethylene glycol (MEG) production capacity is included in force majeure declarations.

Three producers in southwestern Louisiana and southeastern Texas – Lotte, Indorama and Sasol – declared force majeure as a result of the category 4 storm, which hit the area early morning on 27 August.

These three plants represent 35% of US MEG capacity, according to the ICIS Supply and Demand Database.

Power outages remain in the US as a result of Hurricane Laura, preventing some chemical companies from restarting their plants.

US MEG supply was already tight, ahead of a heavy slate of planned maintenance.

Click here to view the US Gulf storms – impacts on chemicals topic page.

MEG is an intermediate in the production of polyester fibres and polyethylene terephthalate (PET) bottle resins, and as an automotive antifreeze.

Major glycol producers in the US include Eastman Chemical, Indorama Ventures, Lotte Chemical, LyondellBasell, MEGlobal, Nan Ya Plastics, Sasol and Shell Chemical.

September 2, 2020

Power outages remain high, delay chem plant restarts

Author: Al Greenwood

2020/09/02

HOUSTON (ICIS)–Power outages have persisted on Wednesday in Louisiana and Texas, making it harder for petrochemical plants to resume operations.

Many plants remain shut down in part because of power outages, even though they escaped major damage from Hurricane Laura. The storm made landfall early on 27 August in Louisiana, close to the border with Texas.

The number of power outages reported by utilities remains high, as shown in the following table.

| 1-Sep | 2-Sep | |

| Louisiana | 260,770 | 227,430 |

| Texas | 39,008 | 41,330 |

Source: PowerOutage.US

Entergy is the main power distributor in the regions hit hardest by the storm. The company is focusing on restoring power to critical community infrastructure such as fire and police departments, hospitals, water utilities and communications services, it said, adding, “As we restore service to residential, commercial and industrial customers, we must do it in a way that balances the needs of our customers with the ability to support additional load as the system permits.”

Entergy gave no timeline as to when it could restore power to industrial plants.

A synthetic rubber producer said one plant may not get power until mid-September.

PLANT UPDATES

Covestro declared force majeure on toluene diisocyanate (TDI) supplies in North America as of 1 September, according to a company spokesperson.

The company said that the force majeure declaration was necessitated by the recent shutdown of the company’s facility in Baytown, Texas, ahead of the arrival of Hurricane Laura, along with an unforeseen shortage of a key raw material used in production.

Baytown is near Houston, which saw few effects from the storm. Nevertheless, many companies in the region shut down operations as a precaution.

Plants farther away from the landfall site suffered little damage and are resuming operations.

Capacity for some products was clustered around the area hit by Hurricane Laura, which caused a large portion of US production for those products to be shut down.

September 2, 2020

Power outages remain high, delay chem plant restarts

Author: Al Greenwood

2020/09/02

HOUSTON (ICIS)–Power outages have persisted on Wednesday in Louisiana and Texas, making it harder for petrochemical plants to resume operations.

Many plants remain shut down in part because of power outages, even though they escaped major damage from Hurricane Laura. The storm made landfall early on 27 August in Louisiana, close to the border with Texas.

The number of power outages reported by utilities remains high, as shown in the following table.

| 1-Sep | 2-Sep | |

| Louisiana | 260,770 | 227,430 |

| Texas | 39,008 | 41,330 |

Source: PowerOutage.US

Entergy is the main power distributor in the regions hit hardest by the storm. The company is focusing on restoring power to critical community infrastructure such as fire and police departments, hospitals, water utilities and communications services, it said, adding, “As we restore service to residential, commercial and industrial customers, we must do it in a way that balances the needs of our customers with the ability to support additional load as the system permits.”

Entergy gave no timeline as to when it could restore power to industrial plants.

A synthetic rubber producer said one plant may not get power until mid-September.

PLANT UPDATES

Covestro declared force majeure on toluene diisocyanate (TDI) supplies in North America as of 1 September, according to a company spokesperson.

The company said that the force majeure declaration was necessitated by the recent shutdown of the company’s facility in Baytown, Texas, ahead of the arrival of Hurricane Laura, along with an unforeseen shortage of a key raw material used in production.

Baytown is near Houston, which saw few effects from the storm. Nevertheless, many companies in the region shut down operations as a precaution.

Plants farther away from the landfall site suffered little damage and are resuming operations.

Capacity for some products was clustered around the area hit by Hurricane Laura, which caused a large portion of US production for those products to be shut down.

September 1, 2020

US Manufacturing Storms Ahead: ISM Smashes Expectations As New Orders Soar To 16 Year High

by Tyler Durden Tue, 09/01/2020 – 10:14

Following more rebounds in ‘soft’ manufacturing survey data in Europe and Asia (and LatAm – Brazil Manufacturing PMI exploded to a record in July), both ISM and Markit’s measures of US manufacturing sentiment were expected to continue their v-shaped recovery, and they did just that, when first the Markit PMI printed at 53.1, the highest level since January 2019, followed by the ISM Manufacturing, which smashed expectations, printing at 56.0, the highest since November 2018.

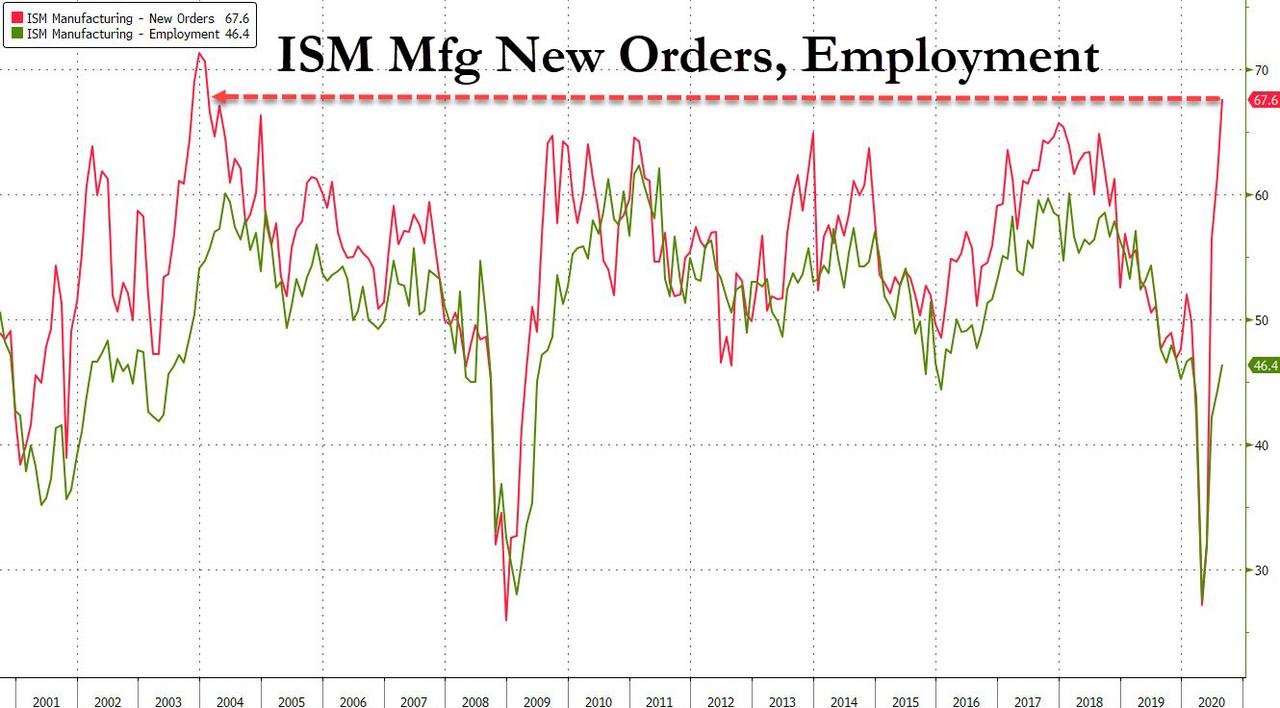

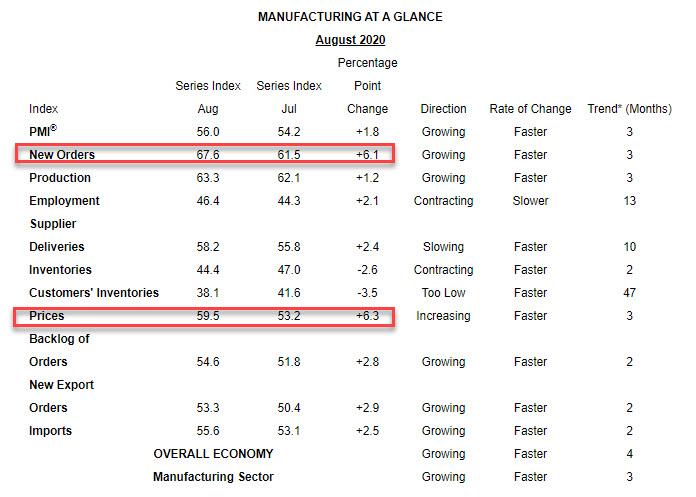

Just like last month, the ISM surge was driven largely by New Orders which spiked from 61.5 to 67.6, the highest level since Jan 2004, and while employment continued to rise, from 44.3 to 46.4, it remains in contraction territory.

Looking across the data, virtually all ISM components improved with the exception of Inventories which dipped for both producers and customers, a sign that destocking is taking place and which is actually bullish for even more future demand.

On ISM, Chair Timothy Fiore said that “The August PMI registered 56 percent, up 1.8 percentage points from the July reading of 54.2 percent. This figure indicates expansion in the overall economy for the fourth month in a row after a contraction in April, which ended a period of 131 consecutive months of growth. The New Orders Index registered 67.6 percent, an increase of 6.1 percentage points from the July reading of 61.5 percent. The Production Index registered 63.3 percent, up 1.2 percentage points compared to the July reading of 62.1 percent. The Backlog of Orders Index registered 54.6 percent, an increase of 2.8 percentage points compared to the July reading of 51.8 percent. The Employment Index registered 46.4 percent, an increase of 2.1 percentage points from the July reading of 44.3 percent. The Supplier Deliveries Index registered 58.2 percent, up 2.4 percentage points from the July figure of 55.8 percent.

Looking ahead, Fiore said : “Don’t see why this can’t continue, maybe not as strong, pretty good shape.”

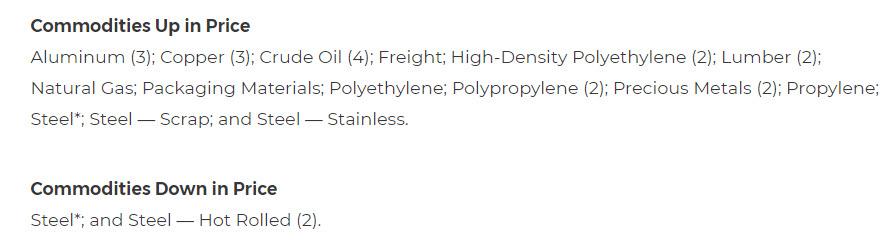

And while the Fed is desperate to average inflation higher, the ISM confirmed that at the commodity level, virtually everything was more expensive:

Meanwhile, unlike last month, when the Markit PMI unexpectedly missed, this time there was convergence between the two series, with Markit noting that the strongest Mfg PMI since Jan 2019 “was underpinned by stronger new order growth as exports rose at the quickest pace for four years.”

The ISM Survey respondents were mixed even as optimism about the future seemed to prevail (except for airlines), although some expressed concerns about the ongoing covid crisis, while others noted that some weakness is starting to emerge:

- “Watching COVID-19 situations in Mexico, Brazil, Philippines [and] Hong Kong. High rates of COVID-19 surging. Currently, lines of supply no longer impacted by COVID-19 related events.” (Computer & Electronic Products)

- “Business is very good. Production cannot keep up with demand. Some upstream supply chains are starting to have issues with raw material and/or transportation availability.” (Chemical Products)

- “Airline industry continues to be under great pressure.” (Transportation Equipment)

- “Current sales to domestic markets are substantially stronger than forecasted. We expected a recession, but it did not turn out that way. Retail and trade customer markets are very strong and driving shortages in raw material suppliers, increasing supplier orders.” (Fabricated Metal Products)

- “Homebuilder business continues to be robust, with month-over-month gains continuing since May. Business remains favorable and will only be held back by supply issues across the entire industry.” (Wood Products)

- “We are seeing solid month-over-month order improvement in all manufacturing sectors such as electrical, auto and industrial goods. Looking to add a few factory operators.” (Plastics & Rubber Products)

- “Rolling production forecasts are increasing each week compared to prior forecast.” (Primary Metals)

- “[Production ramp-up] has been a struggle. We have started and stopped lines numerous times at all 18 of our manufacturing plants due to COVID-19 issues. Surprisingly, our direct suppliers have done an excellent job on shipping ingredients and packaging on time.” (Food, Beverage & Tobacco Products)

- “Strong demand from existing and new customers for our products, stable-to-decreasing input costs for our operations, and record numbers of new business opportunities from prospective customers’ reshoring measures. All trends continuing from the first quarter of fiscal year 2017.” (Electrical Equipment, Appliances & Components)

- “Capital equipment new orders have slowed again. Quoting is active. Many customers waiting for the fourth quarter to make any commitments.” (Machinery)

- “We are starting to see parts of our business rebound in August, while other parts remained weak. Some of our export business has come back for the first time since the start of COVID-19; however, domestic portfolios remain mixed.” (Paper Products)

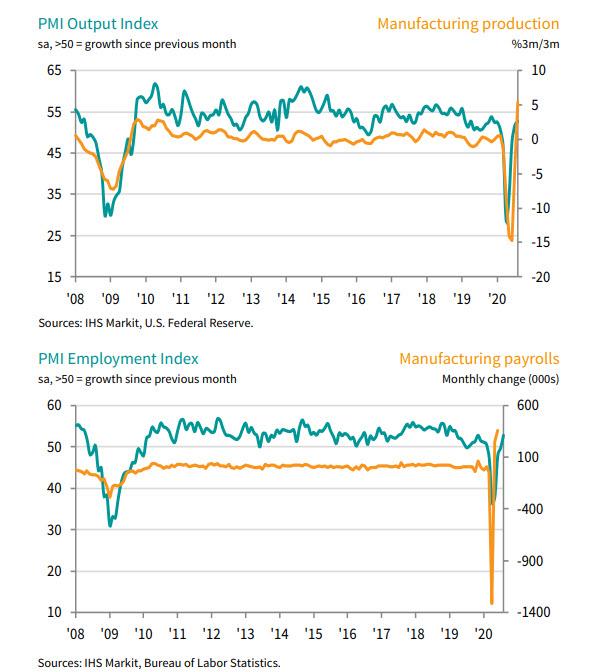

On PMI, Chris Williamson, Chief Business Economist at IHS Markit notes, made an interesting observation: while new export orders surged, “new orders and export sales at smaller manufacturers continued to fall, highlighting an unbalanced recovery in favor of larger firms.“

“The manufacturing upturn gained further ground in August, adding to indications that the third quarter should see a strong rebound in production from the steep decline suffered in the second quarter.

“Encouragingly, new order inflows improved markedly, outpacing production to leave many companies struggling to produce enough goods to meet demand, often due to a lack of operating capacity. Backlogs of uncompleted work consequently rose at the fastest rate since the early months of 2019, encouraging increasing numbers of firms to take on more staff.

“Key to the upturn was a jump in new export orders, which rose at the fastest rate for four years, reflecting improving demand in many foreign markets, and benefitting larger companies in particular. Disappointingly, new orders and export sales at smaller manufacturers continued to fall, highlighting an unbalanced recovery in favor of larger firms.

Overall a strong report for the month of August which may end up being a problem for the broader economy as it eliminates the need for an urgent intervention by Congress to reboot the fiscal spending that expired on July 31.