The Urethane Blog

Everchem Updates

VOLUME XXI

September 14, 2023

Everchem’s exclusive Closers Only Club is reserved for only the highest caliber brass-baller salesmen in the chemical industry. Watch the hype video and be introduced to the top of the league: — read more

September 9, 2019

Share this article DOWNERS GROVE, Ill., Aug. 30, 2019 /PRNewswire/ — Univar Inc. (NYSE: UNVR) (“Univar Solutions”), a global chemical and ingredient distributor and provider of value-added services, has been selected as BASF’s exclusive authorized distributor for Lupragen® amine catalysts throughout the United States. As a leader in chemicals and raw materials for coatings, adhesives, sealants, and elastomers (CASE) applications, Univar Solutions is well positioned to represent these specialty products in the polyurethane markets. “We are excited about expanding our specialty portfolio with Lupragen®,” said Joey Gullion, vice president, focused industries in the United States for Univar Solutions. “This broad line of catalysts fits extremely well with our complimentary product mix in the polyurethane space. Leveraging these products, along with our strong distribution network and technical capabilities, will deliver the right solutions to our mutual customers.” BASF has more than 15 polyurethane (PUR) amine catalysts in its product portfolio, making it a world leader in this segment. The company markets high-performance reaction accelerators under the Lupragen® brand, including extremely low-emission PUR catalysts. Such catalysts are usually tertiary amines. They are required to facilitate the reaction of the main components’ isocyanate and polyol. Depending on the catalyst choice, the polyurethane forming process can be controlled to favor the gelling or blowing reaction. This behavior leads to PUR material with the desired properties, depending on whether the final product is to be a rigid, semi-rigid or flexible foam. As one of the world’s leading chemical companies, BASF offers excellent and consistent product quality, high supplier reliability, and worldwide product availability with dedicated production facilities in Europe and North America. About Univar Solutions https://www.prnewswire.com/news-releases/univar-solutions-selected-as-national-us-distributor-for-basfs-lupragen-300909566.htmlUnivar Solutions Selected as National U.S. Distributor for BASF’s Lupragen®

Univar Solutions (NYSE: UNVR) is a leading global chemical and ingredient distributor and provider of value added services to customers across a wide range of industries. With the industry’s largest private transportation fleet and North American sales force, a vast supplier network, deep market and regulatory knowledge, world-class formulation and recipe development, unparalleled logistics know-how, and industry-leading digital tools, Univar Solutions is a committed ally to customers and suppliers, helping them anticipate, navigate, and leverage meaningful growth opportunities. Learn more at univarsolutions.com.

September 6, 2019

FoamPartner: Ether-based PU foams with low emission levels

FoamPartner Hall 10 Stand 504

The Swiss company FoamPartner Fritz Nauer AG has developed a foam product family, which is characterised by very low emission levels for use in automotive headliners with high demands on processability and design. The new ether-based foam technology is said to combine high surface quality with lowest volatile organic compounds (VOC) and fogging (FOG) values. The company will present the new products at Foam Expo Europe 2019 from 10 – 12 September 2019 in Stuttgart, Germany.

Thanks to their homogenous and fine-pore cell structure, OBoSky foams deliver uniform surfaces, ideal in particular for high-quality automotive headliners (Source: Getty Images/algre)

According to the manufacturer, the foams sold under the OBoSky brand name benefit from a patented ether prepolymer technology to combine the advantages of ester-based polyurethane foams with those of ether-based materials. The result is a family of hydrolytically stable, low-emission and low-odour foams with good processability and a very homogenous cell structure. The technology is especially targeted to demanding automotive headliners. However, thanks to their high elongation and good resilience, the foams also have an ideal fit in further automotive interior applications requiring a pleasant soft feel, said the company.

“Vehicles off the shelf are history. Besides looking for an environmentally friendly as possible drive system, consumers today have a keen eye for a stylish interior design using materials that ensure a healthy climate in the passenger compartment,” said Klaus Hellmold, Vice President Global Business Unit Automotive Rolls at FoamPartner. “With our OBoSky foams for headliners, we have set new standards in efficient processing and environmental compatibility.”

In tests according to VDA 278 and VDA 270, the new PU foams stay clearly below the VOC and FOG levels specified by Daimler’s DBL 5450 soft foam standard (Source: FoamPartner)

The headliner foam grades are said to feature a very uniform structure with fine pores, providing surfaces that can easily be laminated in flame and adhesion processes while also lending themselves to finishing textiles of low surface weight. The ether-based prepolymer technology of the materials is said to ensure very good hydrolytic resistance and long-term high mechanical properties as well as to lead to significantly lower levels in VOC and FOG vs. merely ester-based foams. In VOC and FOG tests according to VDA 278 and VDA 270, OBoSky is said to show values clearly below the limits specified in DBL 5450, the supply regulation of Daimler AG for flexible foams based on polyurethane.

The products are available in rolls and various net densities as well as with or without flame protecting finish according to FMVSS 302. The manufacturing process enables a block foam length of 120 m, which results in 50 % fewer bonding seams compared to common 60 m blocks in the market. This means customers can save costs in their end-product fabrication, said the company.

https://www.gupta-verlag.com/news/technology/23180/foampartner-ether-based-pu-foams-with-low-emission-levels

September 6, 2019

FoamPartner: Ether-based PU foams with low emission levels

FoamPartner Hall 10 Stand 504

The Swiss company FoamPartner Fritz Nauer AG has developed a foam product family, which is characterised by very low emission levels for use in automotive headliners with high demands on processability and design. The new ether-based foam technology is said to combine high surface quality with lowest volatile organic compounds (VOC) and fogging (FOG) values. The company will present the new products at Foam Expo Europe 2019 from 10 – 12 September 2019 in Stuttgart, Germany.

Thanks to their homogenous and fine-pore cell structure, OBoSky foams deliver uniform surfaces, ideal in particular for high-quality automotive headliners (Source: Getty Images/algre)

According to the manufacturer, the foams sold under the OBoSky brand name benefit from a patented ether prepolymer technology to combine the advantages of ester-based polyurethane foams with those of ether-based materials. The result is a family of hydrolytically stable, low-emission and low-odour foams with good processability and a very homogenous cell structure. The technology is especially targeted to demanding automotive headliners. However, thanks to their high elongation and good resilience, the foams also have an ideal fit in further automotive interior applications requiring a pleasant soft feel, said the company.

“Vehicles off the shelf are history. Besides looking for an environmentally friendly as possible drive system, consumers today have a keen eye for a stylish interior design using materials that ensure a healthy climate in the passenger compartment,” said Klaus Hellmold, Vice President Global Business Unit Automotive Rolls at FoamPartner. “With our OBoSky foams for headliners, we have set new standards in efficient processing and environmental compatibility.”

In tests according to VDA 278 and VDA 270, the new PU foams stay clearly below the VOC and FOG levels specified by Daimler’s DBL 5450 soft foam standard (Source: FoamPartner)

The headliner foam grades are said to feature a very uniform structure with fine pores, providing surfaces that can easily be laminated in flame and adhesion processes while also lending themselves to finishing textiles of low surface weight. The ether-based prepolymer technology of the materials is said to ensure very good hydrolytic resistance and long-term high mechanical properties as well as to lead to significantly lower levels in VOC and FOG vs. merely ester-based foams. In VOC and FOG tests according to VDA 278 and VDA 270, OBoSky is said to show values clearly below the limits specified in DBL 5450, the supply regulation of Daimler AG for flexible foams based on polyurethane.

The products are available in rolls and various net densities as well as with or without flame protecting finish according to FMVSS 302. The manufacturing process enables a block foam length of 120 m, which results in 50 % fewer bonding seams compared to common 60 m blocks in the market. This means customers can save costs in their end-product fabrication, said the company.

https://www.gupta-verlag.com/news/technology/23180/foampartner-ether-based-pu-foams-with-low-emission-levels

September 6, 2019

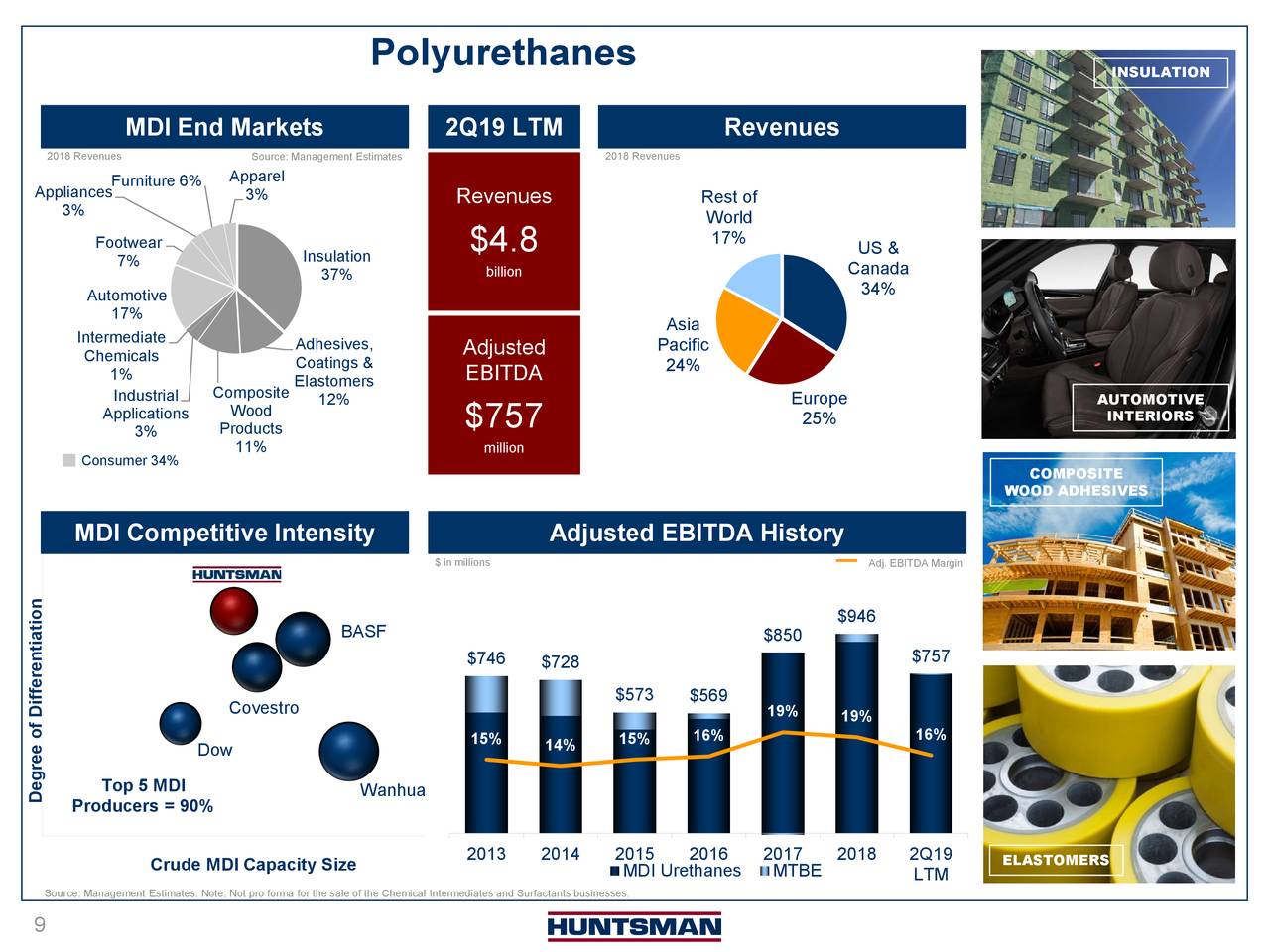

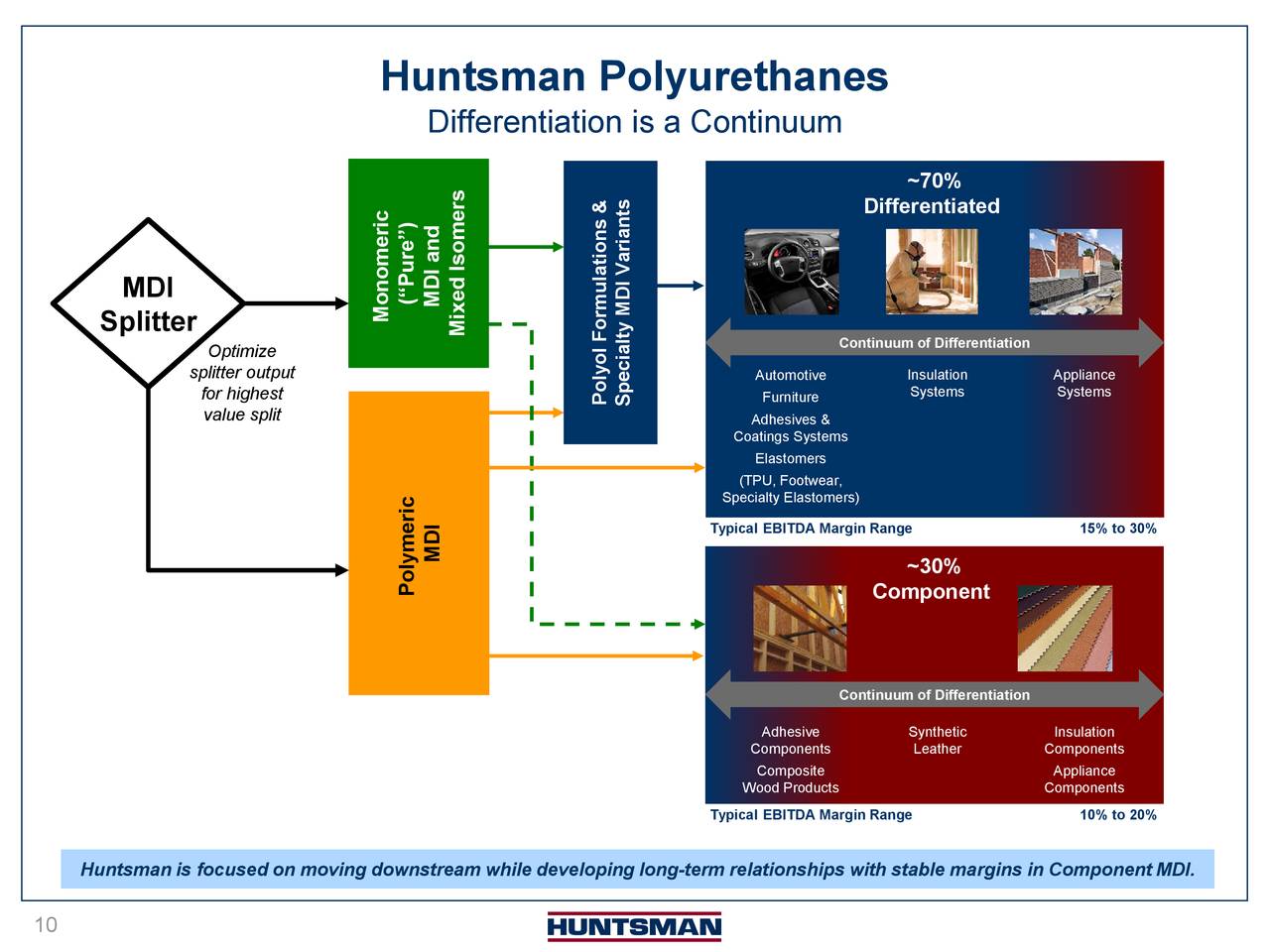

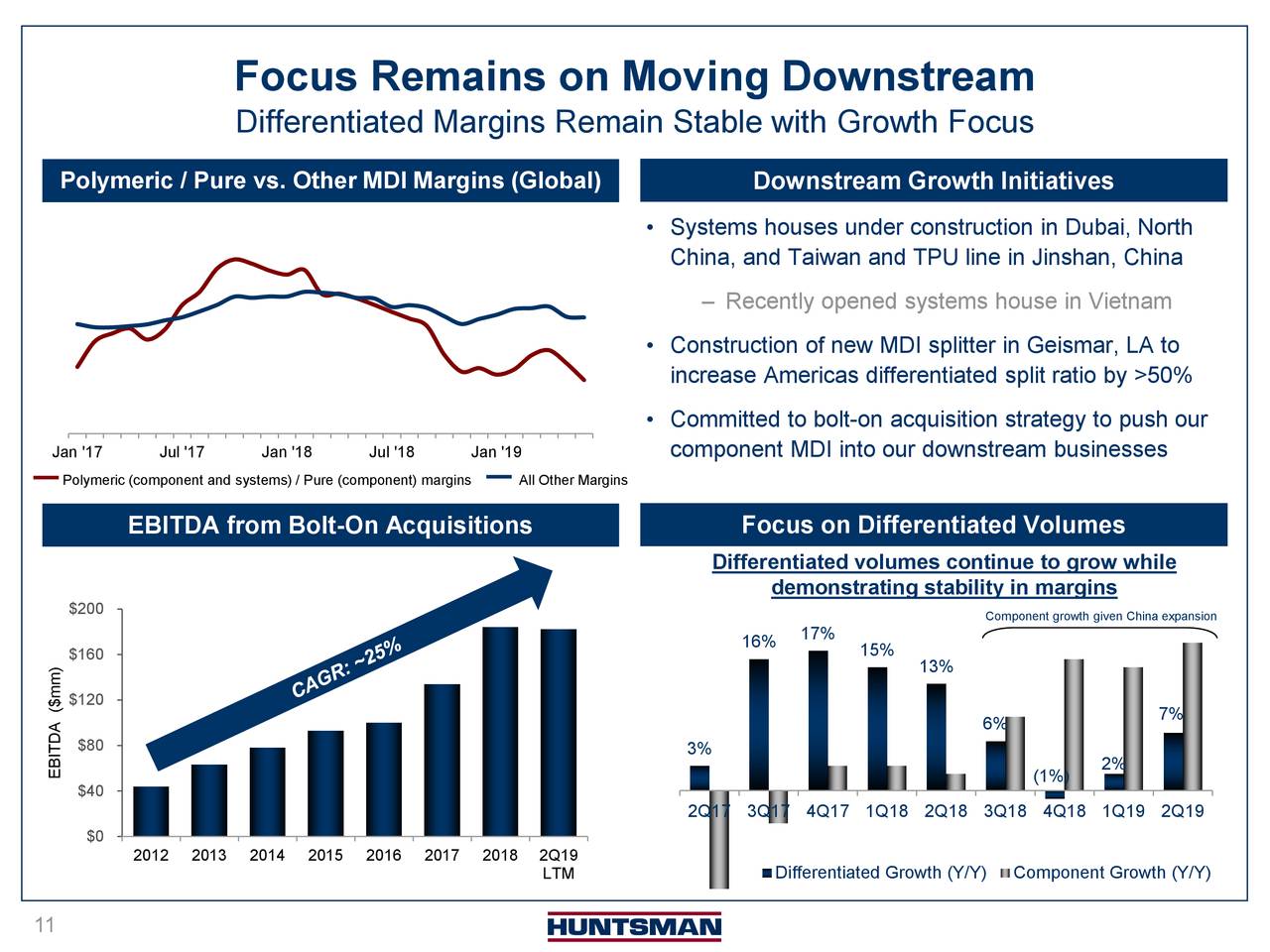

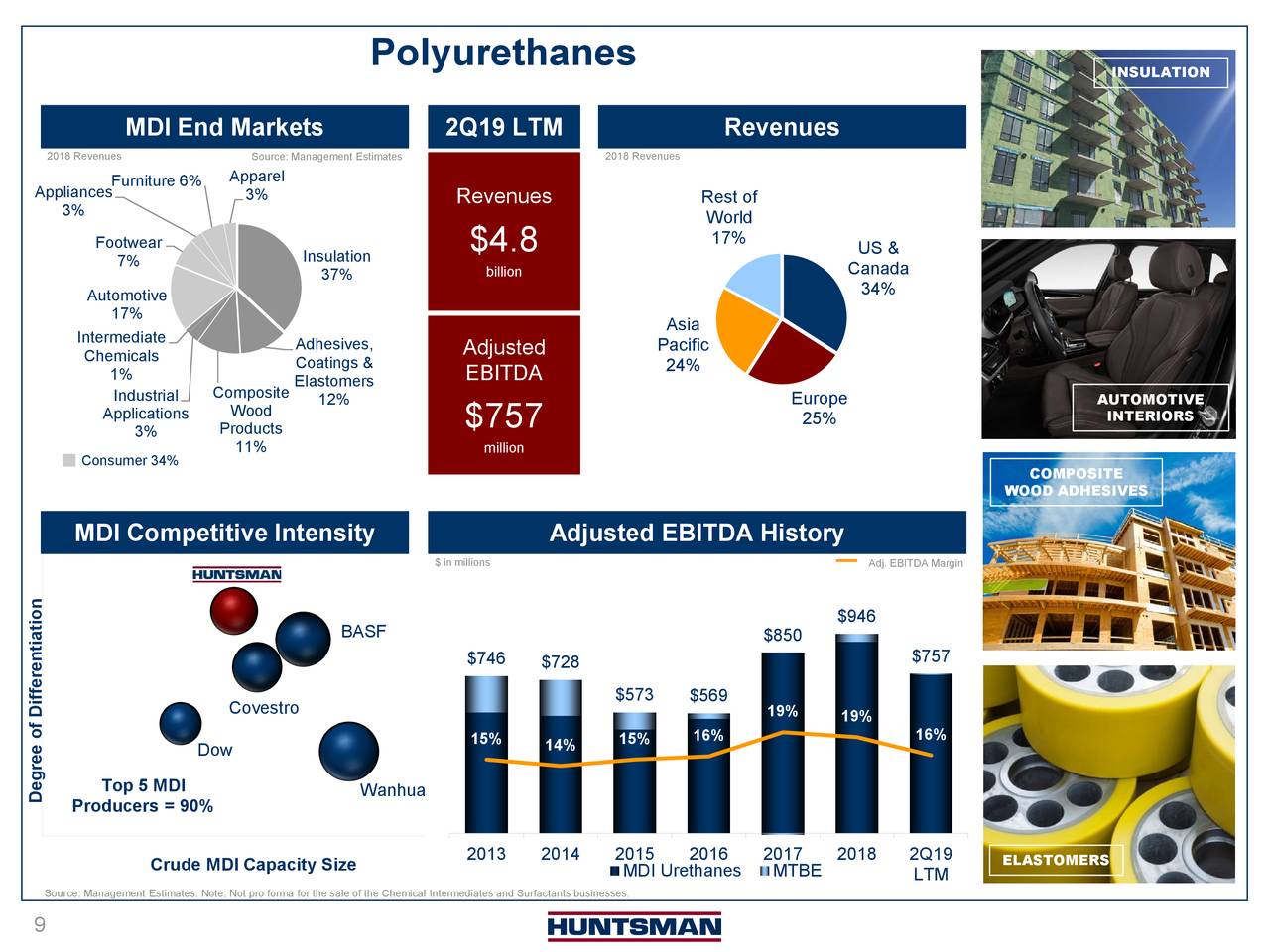

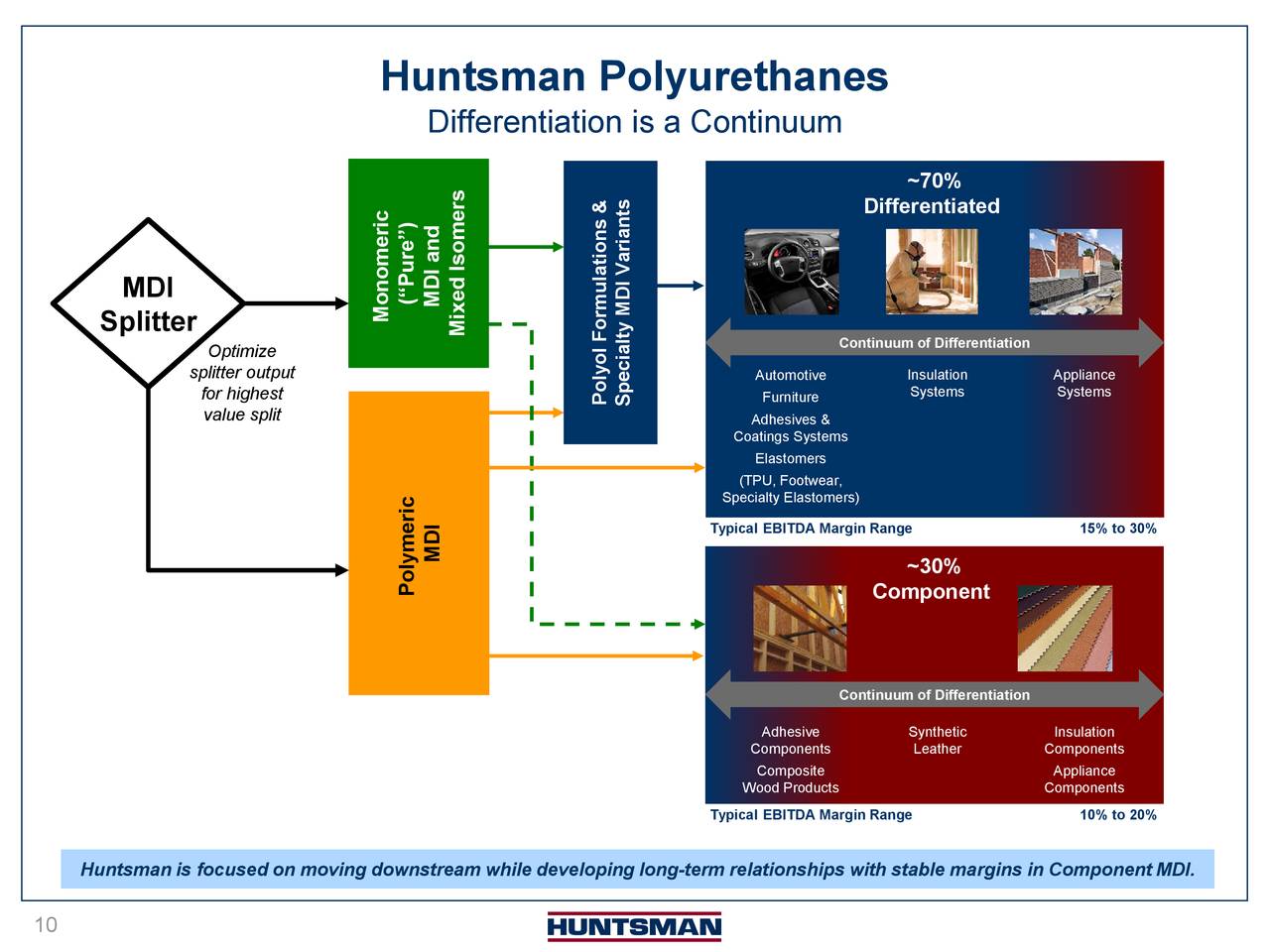

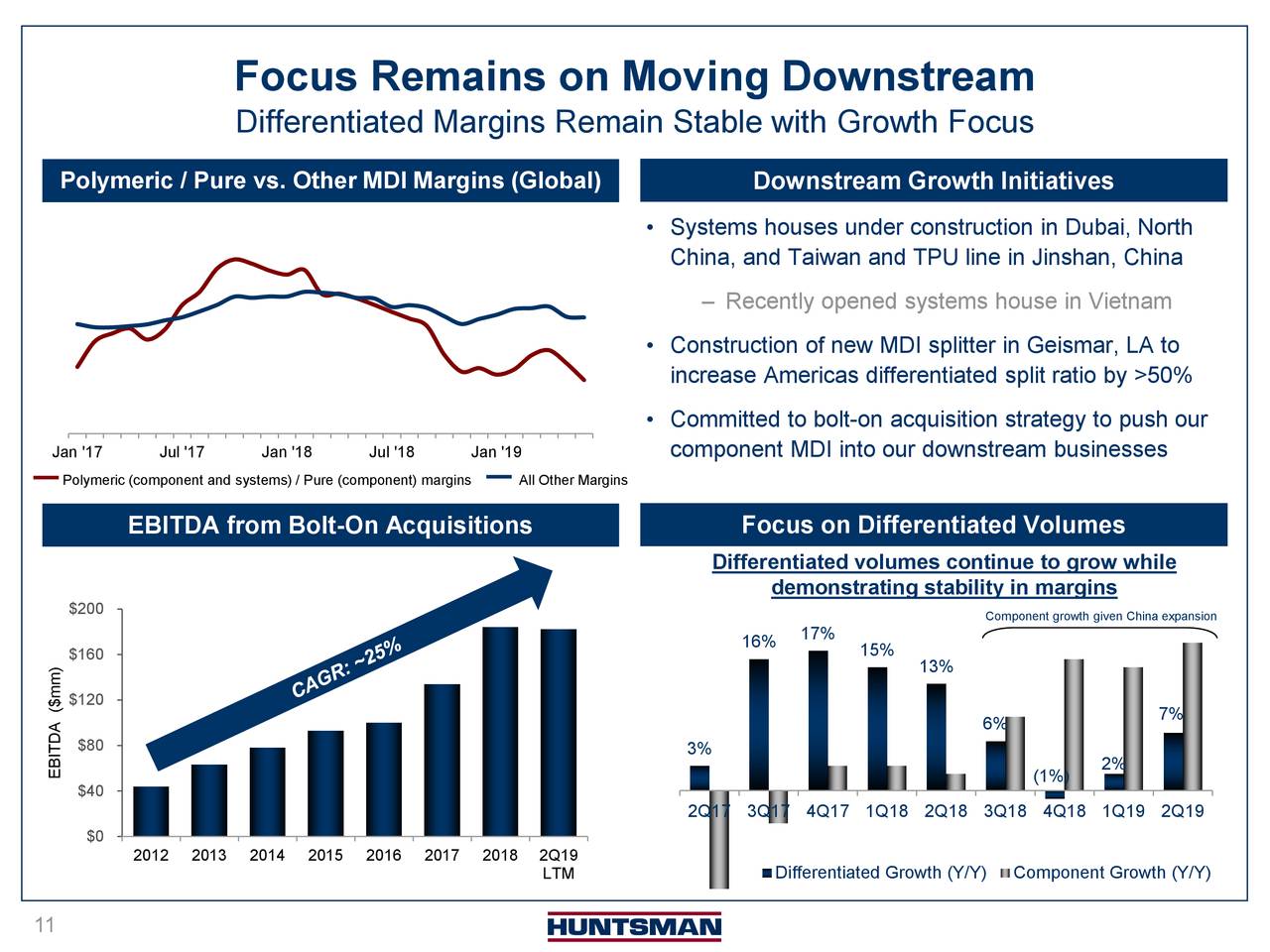

https://seekingalpha.com/article/4289846-huntsman-corporation-hun-presents-ubs-global-chemicals-conference-slideshow

September 6, 2019

https://seekingalpha.com/article/4289846-huntsman-corporation-hun-presents-ubs-global-chemicals-conference-slideshow