The Urethane Blog

Everchem Updates

VOLUME XXI

September 14, 2023

Everchem’s exclusive Closers Only Club is reserved for only the highest caliber brass-baller salesmen in the chemical industry. Watch the hype video and be introduced to the top of the league: — read more

November 23, 2020

Tariffs, delays, construction inflate LyondellBasell PO/TBA costs by 30%

Author: Al Greenwood

2020/10/30

HOUSTON (ICIS)–Because of tariffs, delays and construction, LyondellBasell expects that costs will rise by at least 30% for its new propylene oxide/tertiary butyl alcohol (PO/TBA) project, executives said on Friday.

The $2.4bn PO/TBA project began in August 2018, and it is made up of two parts.

The PO/TBA plant is being built at LyondellBasell’s complex in Channelview, Texas. Once finished, the plant will produce 2.2bn lb/year (1m tonnes/year) of TBA and 1bn lb/year of PO.

The second part – about $640m of the $2.4bn project – will expand the company’s complex in Bayport, Texas. The new capacity will convert TBA into mainly ethyl tertiary butyl ether (ETBE), although it will have the flexibility to produce methyl tertiary butyl ether (MTBE) as well.

Back in March, LyondellBasell said it was slowing down construction at the site to preserve capital and to limit the spread of the coronavirus.

The delay pushed the completion date for the project by about a year to the fourth quarter of 2022, said Michael McMurray, chief financial officer. He made his comments during an earnings conference call.

“Higher costs arising from the delayed project execution, more extensive civil construction and unexpected tariffs on materials are expected to add at least 30% to our original cost estimate of $2.4bn,” he said.

The delay does have a positive side. It could help with the timing of the start-up of the project, so it corresponds with a stronger economy, McMurray said.

Nonetheless, the combined effects of the delay, the tariffs and the construction will lower the returns of the project, said Bob Patel, CEO. He was also on the conference call.

“Certainly returns will be lower. We think probably in the 10% range on returns for PO/TBA,” he said. Still, “I think in the end, we are going to net out the delay of the project”.

The delay gave LyondellBasell a cushion on cash flow in 2020, Patel said. Like McMurray, he noted that the project will start operations when the market is further along in its recovery.

“In the end, balancing near-term needs with long-term market demand, I think this was the right call to make,” Patel said.

November 23, 2020

Tariffs, delays, construction inflate LyondellBasell PO/TBA costs by 30%

Author: Al Greenwood

2020/10/30

HOUSTON (ICIS)–Because of tariffs, delays and construction, LyondellBasell expects that costs will rise by at least 30% for its new propylene oxide/tertiary butyl alcohol (PO/TBA) project, executives said on Friday.

The $2.4bn PO/TBA project began in August 2018, and it is made up of two parts.

The PO/TBA plant is being built at LyondellBasell’s complex in Channelview, Texas. Once finished, the plant will produce 2.2bn lb/year (1m tonnes/year) of TBA and 1bn lb/year of PO.

The second part – about $640m of the $2.4bn project – will expand the company’s complex in Bayport, Texas. The new capacity will convert TBA into mainly ethyl tertiary butyl ether (ETBE), although it will have the flexibility to produce methyl tertiary butyl ether (MTBE) as well.

Back in March, LyondellBasell said it was slowing down construction at the site to preserve capital and to limit the spread of the coronavirus.

The delay pushed the completion date for the project by about a year to the fourth quarter of 2022, said Michael McMurray, chief financial officer. He made his comments during an earnings conference call.

“Higher costs arising from the delayed project execution, more extensive civil construction and unexpected tariffs on materials are expected to add at least 30% to our original cost estimate of $2.4bn,” he said.

The delay does have a positive side. It could help with the timing of the start-up of the project, so it corresponds with a stronger economy, McMurray said.

Nonetheless, the combined effects of the delay, the tariffs and the construction will lower the returns of the project, said Bob Patel, CEO. He was also on the conference call.

“Certainly returns will be lower. We think probably in the 10% range on returns for PO/TBA,” he said. Still, “I think in the end, we are going to net out the delay of the project”.

The delay gave LyondellBasell a cushion on cash flow in 2020, Patel said. Like McMurray, he noted that the project will start operations when the market is further along in its recovery.

“In the end, balancing near-term needs with long-term market demand, I think this was the right call to make,” Patel said.

November 23, 2020

Press Release: November 23, 2020 Richmond, VA.

It is with great sadness that Carpenter Co. announces that

Stanley F. Pauley has passed away at the age of 93. Until

several weeks ago, he had remained engaged in the daily

activities of the company he had led for more than 40 years.

“The term visionary is often over used, but in the case of Stan,

it would be a completely accurate description” said Brad Beauchamp President & C.E.O. “He was one of the true giants in our industry who saw polyurethanes grow from its

infancy into the premier material choice for comfort and insulation applications.”

Stan was hired by E. Rhodes Carpenter in 1954 and moved from Canada to Richmond, Virginia. At that time, Carpenter was making seating cushions out of latex foam. In the early 1960s, with Mr. Carpenter’s blessing, Stan and a small group of executives made the decision to switch to manufacturing urethane foam, which at that time involved making a prepolymer and molding foam. Shortly thereafter, Union Carbide helped Carpenter implement the one-shot process which forms the basis of how most urethane foams are made today. Throughout the ensuing decades, the company embarked on an expansion strategy that initially focused on North America but eventually included acquisitions in Europe. The expansions were largely directed by Mr. Pauley. In addition to increasing the flexible urethane foam production footprint, in 1970 Carpenter Co. broke with convention and opened a greenfield site for the production of polyether polyols. Upon the death of Mr. Carpenter in the early 1980’s, Stan became Chairman & CEO and the majority shareholder. The company continues to be owned by the Pauley family.

Today Carpenter is one of the largest manufacturers of flexible foam in the world and is one of the largest producers of polyether polyols in North America, which not only supplies Carpenter but is a major raw material supplier to other segments of the urethane industry. Carpenter has 17 foam pouring plants as well as 25 other locations and over 4,200 employees.

It is also a leader in rebonded foam for carpet underlay as well as Chemical Systems, Tire Fill, Polyester Fiber and Expanded Polystyrene. In addition to his numerous industry recognitions, he supported a variety of educational and philanthropic institutions including the VCU Health Pauley Heart Center, the VCU School of Engineering, Hampden-Sydney College, the University of Manitoba and the Virginia Museum of Fine Arts.

“It was his vision that Carpenter Co. should remain an independent privately held company because that was the best way to ensure clear decision making and strategic focus. He believed in investing in equipment and training. With his passing, it will fall upon the rest of us to ensure

that the company remains true to that vision. We are fortunate that he had the foresight to structure the company in a way that will help keep that a reality.”

November 23, 2020

Press Release: November 23, 2020 Richmond, VA.

It is with great sadness that Carpenter Co. announces that

Stanley F. Pauley has passed away at the age of 93. Until

several weeks ago, he had remained engaged in the daily

activities of the company he had led for more than 40 years.

“The term visionary is often over used, but in the case of Stan,

it would be a completely accurate description” said Brad Beauchamp President & C.E.O. “He was one of the true giants in our industry who saw polyurethanes grow from its

infancy into the premier material choice for comfort and insulation applications.”

Stan was hired by E. Rhodes Carpenter in 1954 and moved from Canada to Richmond, Virginia. At that time, Carpenter was making seating cushions out of latex foam. In the early 1960s, with Mr. Carpenter’s blessing, Stan and a small group of executives made the decision to switch to manufacturing urethane foam, which at that time involved making a prepolymer and molding foam. Shortly thereafter, Union Carbide helped Carpenter implement the one-shot process which forms the basis of how most urethane foams are made today. Throughout the ensuing decades, the company embarked on an expansion strategy that initially focused on North America but eventually included acquisitions in Europe. The expansions were largely directed by Mr. Pauley. In addition to increasing the flexible urethane foam production footprint, in 1970 Carpenter Co. broke with convention and opened a greenfield site for the production of polyether polyols. Upon the death of Mr. Carpenter in the early 1980’s, Stan became Chairman & CEO and the majority shareholder. The company continues to be owned by the Pauley family.

Today Carpenter is one of the largest manufacturers of flexible foam in the world and is one of the largest producers of polyether polyols in North America, which not only supplies Carpenter but is a major raw material supplier to other segments of the urethane industry. Carpenter has 17 foam pouring plants as well as 25 other locations and over 4,200 employees.

It is also a leader in rebonded foam for carpet underlay as well as Chemical Systems, Tire Fill, Polyester Fiber and Expanded Polystyrene. In addition to his numerous industry recognitions, he supported a variety of educational and philanthropic institutions including the VCU Health Pauley Heart Center, the VCU School of Engineering, Hampden-Sydney College, the University of Manitoba and the Virginia Museum of Fine Arts.

“It was his vision that Carpenter Co. should remain an independent privately held company because that was the best way to ensure clear decision making and strategic focus. He believed in investing in equipment and training. With his passing, it will fall upon the rest of us to ensure

that the company remains true to that vision. We are fortunate that he had the foresight to structure the company in a way that will help keep that a reality.”

November 19, 2020

Existing Home Sales Soar To Highest In 15 Years

by Tyler Durden Thu, 11/19/2020 – 10:07

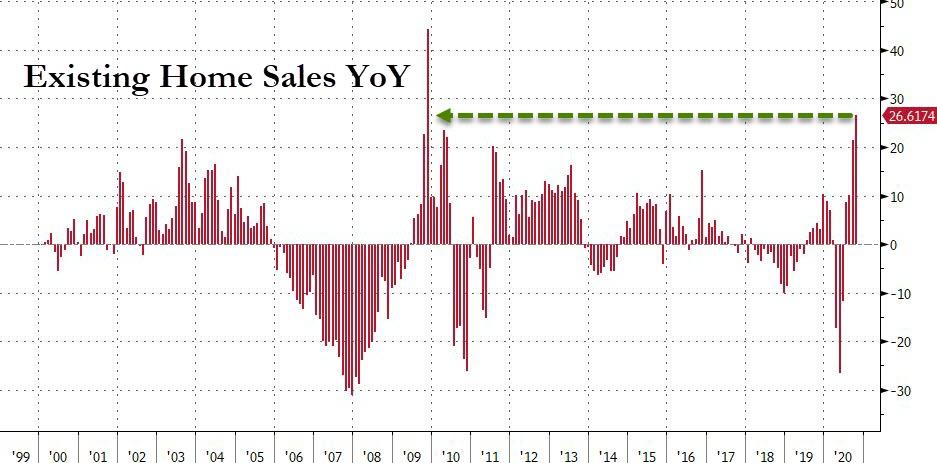

Existing home sales bucked the trend in September (rising to highest since May 2006 as new- and pending-home sales slipped) and analysts expect it too catch down a little in October, but yet again, it surprised to the upside, surging 4.3% MoM (vs a 1.1% MoM expected drop), and September’s jump was revised higher to a 9.9% spike…

This surprise rise has pushed the YoY jump in sales to 26.6% – the biggest spike since Nov 2009

Source: Bloomberg

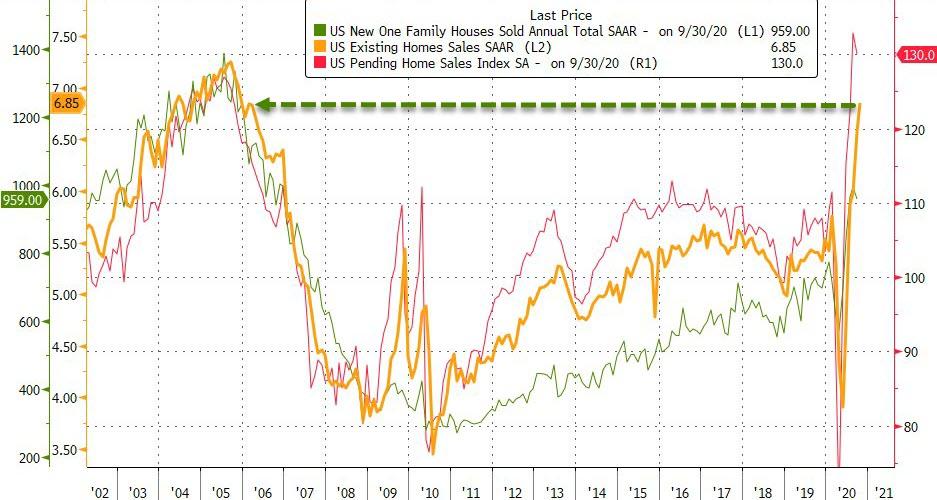

This is the highest existing home sales print since November 2005…

Source: Bloomberg

Christophe Barraud explains why the number was so ‘surprisingly’ good:

- Buyers continued to benefit from favorable market conditions in October with mortgage rates still close to the lowest level on record

- Local/state reports confirm that sales kept rising by more than 20% YoY (non-seasonally adjusted: NSA) in October, which should translate into a bounce on a MoM basis (seasonally adjusted: SA)

- Recent announcements from corporates suggest that home-improvement activity (correlated to existing home sales) is still booming

Median home price rose 15.5% from last year to $313,000, an all-time high, according to NAR.

“It’s quite amazing, and certainly surprising me,” Lawrence Yun, NAR’s chief economist, said on a call with reporters.

“It’s quite remarkable given that we’re still in the midst of the pandemic and the high unemployment rate.”

Finally, we note that while homebuilder sentiment is at record highs (but building permits stumbled?), homebuyer sentiment remains low and has rolled over…

Source: Bloomberg

And don’t expect The Fed to come to the rescue with ‘rate-cuts’ anytime soon.

https://www.zerohedge.com/personal-finance/existing-home-sales-soar-highest-15-years