The Urethane Blog

Everchem Updates

VOLUME XXI

September 14, 2023

Everchem’s exclusive Closers Only Club is reserved for only the highest caliber brass-baller salesmen in the chemical industry. Watch the hype video and be introduced to the top of the league: — read more

July 21, 2022

Dow reports second quarter 2022 results

FINANCIAL HIGHLIGHTS

• GAAP earnings per share (EPS) was $2.26; Operating EPS1 was $2.31, compared to $2.72 in the year-ago

period and $2.34 in the prior quarter. Operating EPS excludes significant items in the quarter, totaling $0.05 per

share, primarily related to digitalization program costs.

• Net sales were $15.7 billion, up 13% versus the year-ago period with gains in all operating segments and

regions. Sequentially, sales were up 3% with gains in all regions except Asia Pacific, which was impacted by

pandemic-related lockdowns in China.

• Local price increased 16% versus the year-ago period, reflecting gains in all operating segments, businesses,

and regions. Currency decreased net sales by 3% year-over-year due to broad-based strength of the U.S.

dollar. Sequentially, local price increased 6% with gains in all operating segments and regions.

• Volume was consistent with the year-ago period, as gains in Packaging & Specialty Plastics were primarily

offset by declines in Industrial Intermediates & Infrastructure. Sequentially, volume declined 2%, driven by

declines primarily in Europe and China.

• Equity earnings were $195 million, down $83 million from the year-ago period, primarily due to impacts from

pandemic-related lockdowns in China. Equity earnings were up $21 million from the prior quarter, driven by

gains at Sadara.

• GAAP Net Income was $1.7 billion. Operating EBIT1 was $2.4 billion, down $453 million versus the year-ago

period. Gains in the Performance Materials & Coatings segment were more than offset by higher raw material

and energy costs across the company as well as lower equity earnings. Sequentially, operating EBIT decreased

2%, as gains in Packaging & Specialty Plastics were more than offset by declines in Industrial Intermediates &

Infrastructure.

• Cash provided by operating activities – continuing operations was $1.9 billion, down $165 million year-overyear

and up $244 million compared to the prior quarter. Free cash flow1 was $1.4 billion.

• The Company’s proactive actions to redeem outstanding notes totaling $750 million have delivered an annual

interest expense reduction of $27 million and no substantive long-term debt maturities are due until 2027.

• Returns to shareholders totaled $1.3 billion in the quarter, comprised of $800 million in share repurchases and

$505 million in dividends.

CEO QUOTE

Jim Fitterling, chairman and chief executive officer, commented on the quarter:

“Team Dow once again delivered net sales growth both year-over-year and sequentially with price increases across

all operating segments and regions. Our competitive advantages and relentless focus on disciplined execution

enabled us to navigate the impacts of pandemic-related lockdowns in China, continued logistics constraints, and

higher energy and raw material costs. As a result, we increased our cash flow and our share buybacks sequentially.

“We continued to progress our strategy to grow our underlying earnings over the economic cycle by investing in

higher-return, faster-payback projects while capitalizing on long-term growth opportunities. As part of these efforts,

today we announced a series of circularity projects that will enable us to achieve approximately two thirds of our

2030 ‘Stop the Waste’ target as we capture growth for the sustainable and circular solutions our customers are

increasingly demanding.”

Polyurethanes & Construction Chemicals business net sales decreased compared to the year-ago period, as local

price gains were more than offset by local currency and lower volume due to planned maintenance turnaround

activity, third-party outages, and inflationary impacts on demand for consumer durables. Sequentially, net sales

declined as lower volumes from planned maintenance turnaround activity and third-party outages were partly offset

by higher local price.

OUTLOOK

“Looking ahead, the long-term fundamentals driving growth across our end markets remain attractive,” said

Fitterling. “While near-term market conditions are dynamic, we will continue to leverage our diverse, global portfolio

and flexible operating model to capitalize on attractive growth opportunities. The actions we’ve taken to enhance

the resiliency of our business position us well to deliver value across a variety of economic environments. Our

disciplined and balanced approach to capital allocation has delivered higher mid-cycle earnings, an improved credit

profile, and cash generation above pre-pandemic levels. Team Dow remains well-positioned to continue advancing

our “decarbonize and grow” strategy while delivering attractive shareholder remuneration.”

July 21, 2022

Dow reports second quarter 2022 results

FINANCIAL HIGHLIGHTS

• GAAP earnings per share (EPS) was $2.26; Operating EPS1 was $2.31, compared to $2.72 in the year-ago

period and $2.34 in the prior quarter. Operating EPS excludes significant items in the quarter, totaling $0.05 per

share, primarily related to digitalization program costs.

• Net sales were $15.7 billion, up 13% versus the year-ago period with gains in all operating segments and

regions. Sequentially, sales were up 3% with gains in all regions except Asia Pacific, which was impacted by

pandemic-related lockdowns in China.

• Local price increased 16% versus the year-ago period, reflecting gains in all operating segments, businesses,

and regions. Currency decreased net sales by 3% year-over-year due to broad-based strength of the U.S.

dollar. Sequentially, local price increased 6% with gains in all operating segments and regions.

• Volume was consistent with the year-ago period, as gains in Packaging & Specialty Plastics were primarily

offset by declines in Industrial Intermediates & Infrastructure. Sequentially, volume declined 2%, driven by

declines primarily in Europe and China.

• Equity earnings were $195 million, down $83 million from the year-ago period, primarily due to impacts from

pandemic-related lockdowns in China. Equity earnings were up $21 million from the prior quarter, driven by

gains at Sadara.

• GAAP Net Income was $1.7 billion. Operating EBIT1 was $2.4 billion, down $453 million versus the year-ago

period. Gains in the Performance Materials & Coatings segment were more than offset by higher raw material

and energy costs across the company as well as lower equity earnings. Sequentially, operating EBIT decreased

2%, as gains in Packaging & Specialty Plastics were more than offset by declines in Industrial Intermediates &

Infrastructure.

• Cash provided by operating activities – continuing operations was $1.9 billion, down $165 million year-overyear

and up $244 million compared to the prior quarter. Free cash flow1 was $1.4 billion.

• The Company’s proactive actions to redeem outstanding notes totaling $750 million have delivered an annual

interest expense reduction of $27 million and no substantive long-term debt maturities are due until 2027.

• Returns to shareholders totaled $1.3 billion in the quarter, comprised of $800 million in share repurchases and

$505 million in dividends.

CEO QUOTE

Jim Fitterling, chairman and chief executive officer, commented on the quarter:

“Team Dow once again delivered net sales growth both year-over-year and sequentially with price increases across

all operating segments and regions. Our competitive advantages and relentless focus on disciplined execution

enabled us to navigate the impacts of pandemic-related lockdowns in China, continued logistics constraints, and

higher energy and raw material costs. As a result, we increased our cash flow and our share buybacks sequentially.

“We continued to progress our strategy to grow our underlying earnings over the economic cycle by investing in

higher-return, faster-payback projects while capitalizing on long-term growth opportunities. As part of these efforts,

today we announced a series of circularity projects that will enable us to achieve approximately two thirds of our

2030 ‘Stop the Waste’ target as we capture growth for the sustainable and circular solutions our customers are

increasingly demanding.”

Polyurethanes & Construction Chemicals business net sales decreased compared to the year-ago period, as local

price gains were more than offset by local currency and lower volume due to planned maintenance turnaround

activity, third-party outages, and inflationary impacts on demand for consumer durables. Sequentially, net sales

declined as lower volumes from planned maintenance turnaround activity and third-party outages were partly offset

by higher local price.

OUTLOOK

“Looking ahead, the long-term fundamentals driving growth across our end markets remain attractive,” said

Fitterling. “While near-term market conditions are dynamic, we will continue to leverage our diverse, global portfolio

and flexible operating model to capitalize on attractive growth opportunities. The actions we’ve taken to enhance

the resiliency of our business position us well to deliver value across a variety of economic environments. Our

disciplined and balanced approach to capital allocation has delivered higher mid-cycle earnings, an improved credit

profile, and cash generation above pre-pandemic levels. Team Dow remains well-positioned to continue advancing

our “decarbonize and grow” strategy while delivering attractive shareholder remuneration.”

July 19, 2022

BASF confirms final phase of MDI expansion at Geismar Verbund site

- Annual production capacity to be increased to 600,000 metric tons by the middle of the decade

- Total investment of $780 million for the final expansion phase

FLORHAM PARK, NJ and GEISMAR, LA, July 19, 2022 – BASF is moving forward with the final phase of the expansion project for the methylene diphenyl diisocyanate (MDI) plant at its Verbund site in Geismar, Louisiana. With this third step of its multiphase capacity expansion, BASF will increase production capacity to 600,000 metric tons per year by the middle of the decade and support the ongoing growth of its North American MDI customers. The company kicked off the expansion project in 2018 with a staggered approach consisting of three investment phases. The investment in the final expansion phase from 2022 to 2025 amounts to $780 million.

“This investment underlines our commitment to North America and strengthens BASF’s supply reliability and the competitiveness of our customers’ value chains in the region,” said Michael Heinz, Chairman and Chief Executive Officer, BASF Corporation. “As one of BASF’s Verbund sites, the Geismar location is ideally suited for the expansion of our MDI production thanks to its existing infrastructure, reliable raw material supply, skilled workforce and strong community support.”

Leveraging state-of-the-art technology, the expansion will showcase the highest safety standards combined with advanced digitalization in its operations. BASF is now entering the final phase of the expansion, targeted for completion by the end of 2025.

“BASF is committed to growing and partnering with our North American MDI customers, be it in the construction and appliance, transportation, automotive, footwear or furniture sectors,” said Ramkumar Dhruva, President of BASF’s Monomers division. “With this integrated facility, we will continue to support our North American MDI customers by growing our capacity to meet their needs.”

The first phase of the expansion project involving the construction of a new MDI synthesis unit was put in operation in October of 2020. The second phase, which started operations in 2021, expanded several existing upstream units. With the third and final expansion phase, which includes several new upstream units and a splitter, the new overall MDI output of the Geismar complex will increase to 600,000 metric tons.

July 19, 2022

BASF confirms final phase of MDI expansion at Geismar Verbund site

- Annual production capacity to be increased to 600,000 metric tons by the middle of the decade

- Total investment of $780 million for the final expansion phase

FLORHAM PARK, NJ and GEISMAR, LA, July 19, 2022 – BASF is moving forward with the final phase of the expansion project for the methylene diphenyl diisocyanate (MDI) plant at its Verbund site in Geismar, Louisiana. With this third step of its multiphase capacity expansion, BASF will increase production capacity to 600,000 metric tons per year by the middle of the decade and support the ongoing growth of its North American MDI customers. The company kicked off the expansion project in 2018 with a staggered approach consisting of three investment phases. The investment in the final expansion phase from 2022 to 2025 amounts to $780 million.

“This investment underlines our commitment to North America and strengthens BASF’s supply reliability and the competitiveness of our customers’ value chains in the region,” said Michael Heinz, Chairman and Chief Executive Officer, BASF Corporation. “As one of BASF’s Verbund sites, the Geismar location is ideally suited for the expansion of our MDI production thanks to its existing infrastructure, reliable raw material supply, skilled workforce and strong community support.”

Leveraging state-of-the-art technology, the expansion will showcase the highest safety standards combined with advanced digitalization in its operations. BASF is now entering the final phase of the expansion, targeted for completion by the end of 2025.

“BASF is committed to growing and partnering with our North American MDI customers, be it in the construction and appliance, transportation, automotive, footwear or furniture sectors,” said Ramkumar Dhruva, President of BASF’s Monomers division. “With this integrated facility, we will continue to support our North American MDI customers by growing our capacity to meet their needs.”

The first phase of the expansion project involving the construction of a new MDI synthesis unit was put in operation in October of 2020. The second phase, which started operations in 2021, expanded several existing upstream units. With the third and final expansion phase, which includes several new upstream units and a splitter, the new overall MDI output of the Geismar complex will increase to 600,000 metric tons.

July 18, 2022

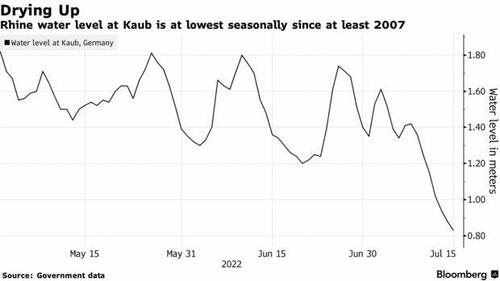

Germany’s Energy Crisis About To Get Even Worse As Rhine Water Levels Plummet

by Tyler DurdenMonday, Jul 18, 2022 – 06:55 AM

What has already been a year from hell for Germany, which is suffering energy hyperinflation as a result of Europe’s sanctions on Russia, and which is “facing the biggest crisis the country has every had” according to the president of the German employers association, is about to get even worse as the declining water level of the Rhine river, which has historically been a key infrastructure transit artery across Germany, continues to fall and as it does, the flow of commodities to inland Europe is starting to buckle threatening to make an already historic crisis even worse.

The alarming lack of water is contributing to oil product supply problems in Switzerland and preventing at least two power plants in Germany from getting all the coal they need, and what’s more, the continent’s sizzling summer temperatures are forecast to climb even higher in the coming week, leading to even lower water levels.

The 800-mile (1,288-kilometer) Rhine river runs from Switzerland all the way to the North Sea and is used to transport tens of millions of tons of commodities through inland Europe. But with water levels at their lowest for the time of year in 15 years, there is a limit how much fuel, coal and other vital cargo that barges can carry up and down the river.

Low water levels on the Rhine River mean that barges hauling middle distillate-type oil products – typically gasoil/diesel – past Kaub in Germany, are limited to loading about 30% of capacity, according to maritime brokerage services firm Riverlake.

A barge loading in the energy hub of Amsterdam-Rotterdam-Antwerp (or ARA), which can haul 2.5k tons when fully laden, is restricted to taking on about 800 tons if sailing to destinations beyond Kaub. As shown below, the water level at Kaub has fallen in recent days and is at its lowest on a seasonal basis since at least 2007. According to Riverlake, further decreases in loading volumes for barges hauling middle distillates from ARA to inland destinations beyond Kaub are expected in coming days.

This – coupled with capacity issues on German railways – has meant that Switzerland is struggling with supplies of oil products, mainly diesel/heating oil, according to Avenergy Suisse, the landlocked country’s organization for fuel importers.

Low Rhine water level combined with capacity problems on German railways are the reasons, managing director Roland Bilang told Bloomberg, adding that supply problems mainly concern diesel/heating oil.

“It has happened from time to time in the past that temporarily not enough mineral oil products could be transported to Switzerland and therefore the compulsory stocks had to be tapped.” Biland recommends private households fill their heating oil tanks early.

Meanwhile, Bloomberg reports that power plants at Mannheim and Karlsruhe in Germany, operated by Grosskraftwerk Mannheim and EnBW, have been struggling to source coal because of the shallow water – just as the country frets that Russia won’t restart flows on a key gas pipeline. The companies said their generation operations aren’t currently affected.

Because of the tight coal market and low Rhine levels making it hard to deliver the fuel, only 65% of Germany’s coal capacity will be available in coming months, according to S&P Global Commodity Insights analyst Sabrina Kernbichler. This is bad news for a country whose biggest energy utilities are starting to drain natgas reserves as a result of the halt in Nord Stream 1 shipments, jeopardising millions of Germans with freezing should the country fail to restock fully ahead of the winter.

Germany also imports oil products up the Rhine, including fuel and heating oil. There’s currently no shortage of gasoline or diesel in the country, according to Herbert Rabl, spokesman for Tankstellen-Interessenverband e.V., which represents fuel station leaseholders and owners in Germany.

Shell – which owns the Wesseling and Godorf refineries along the Rhine – is monitoring the situation, according to a spokesperson.

https://www.zerohedge.com/markets/germanys-crisis-about-get-even-worse-rhine-water-levels-plummet