The Urethane Blog

Everchem Updates

VOLUME XXI

September 14, 2023

Everchem’s exclusive Closers Only Club is reserved for only the highest caliber brass-baller salesmen in the chemical industry. Watch the hype video and be introduced to the top of the league: — read more

March 5, 2021

MEGlobal restarts Texas MEG unit; TPC expects longer restart timeline

- Author

- Kristen Hays

- Editor

- Kshitiz Goliya

- Commodity

- Petrochemicals

Houston —

Efforts to restart petrochemical plants along the US Gulf Coast that shut down amid sustained sub-freezing temperatures in mid-February continued March 4, with downstream derivatives awaiting resumption of production of upstream feedstocks.

MEGlobal has restarted its 750,000 mt/year monoethylene glycol unit in Freeport, Texas, but more than 3 million mt/year of US MEG capacity remained shut, multiple market sources said March 4.

TPC Group expects to restart production units at its Houston petrochemical site the week of March 14, pending restarts of utilities and additional inspections slated for the week of March 8, spokeswoman Sara Cronin said in an email late March 3.

TPC had expected to restart utilities at the Houston site the week of Feb. 28, but found additional freeze-related issues that delayed that initial timeline, she said.

The freeze that affected much of the country reached the US Gulf Coast on Feb. 14, bringing bitter cold temperatures that lasted for more than 72 hours. The freeze prompted petrochemical shutdowns throughout Texas and in parts of Louisiana. The industrial infrastructure in the region was not built to withstand such sustained sub-freezing temperatures, and inspections have been deliberate to seek out any problems with exposed pipes that must be repaired.

“You need to go slow, to make sure there is no leakage on places which cannot be examined visually,” a market source said.

Here is a rundown of the fallout from the freeze:

FORCE MAJEURES

**Dow Chemical: Declared Feb. 19, on 2-ethylhexanol and butanol products from its Texas City, Texas complex

**Formosa Plastics USA: Declared Feb. 19 on US polyethylene

**BASF: Declared Feb. 19 on dioctyl terephthalate, or DOTP, a plasticizer, at its Pasadena, Texas, site

**Westlake Chemical: Declared Feb. 19 on US caustic soda, chlorine, PVC and vinyl chloride monomer (VCM); company has 2.9 million mt/year of US caustic soda capacity, more than 2 million mt/year of PVC capacity, 2.6 million mt/year of VCM; more than 2.26 million mt/year of chlorine capacity at five affected sites

**Formosa Plastics USA: Declared Feb. 18 on US PVC, 1.3 million mt/year of capacity at Point Comfort, Texas, and Baton Rouge, Louisiana, complexes.

**Dow Chemical: Declared Feb. 18 on multiple intermediate chemicals produced at plants in Deer Park, Freeport, Texas City and Bayport Texas, Hahnville, Louisiana, and Louisville, Kentucky; declaration includes VAM, methyl methacrylate (MMA), glacial methacrylic acid (GMAA), butyl methacrylate (BMA), glycidyl methacrylate (GMA), 2-ethylhexyl Acrylate (2EHA), butyl acrylate (BA), and others; Dow informed South American customers

**Celanese: Declared force majeure Feb. 18 on multiple intermediate chemicals normally sold to customers in the US, Europe and the Middle East, including acetic acid, VAM, ethyl acetate and ethylene vinyl acetate (EVA)

**Total: Declared Feb. 17 on polypropylene produced at its 1.15 million mt/year La Porte, Texas, facility

**Formosa Plastics USA: Declared Feb. 17 on all chlor-alkali products

**LyondellBasell: Declared Feb. 16 on styrene monomer

**Vestolit: Declared Feb. 16 on PVC produced at its Colombia and Mexico plants on lack of upstream vinyl chloride monomer feedstock from US suppliers; plants have a combined 1.8 million mt/year of capacity

**Olin: Declared Feb. 16 on US chlorine, caustic soda, ethylene dichloride, epoxy, hydrochloric acid and other products produced at its Freeport, Texas, complex; on Feb. 18 Olin expanded the declaration in a separate letter to customers to include products made system-wide

**MEGlobal: Declared Feb. 15 on MEG produced at its Freeport, Texas, site

**LyondellBasell: Declared Feb. 15 on US polyethylene

**Flint Hills Resources: Declared Feb. 15 on polypropylene produced at Longview, Texas

**OxyChem: Declared Feb. 15 on US chlorine, caustic soda, EDC, VCM and PVC.

**LyondellBasell: Declared Feb. 15 on US polypropylene

**INEOS Olefins and Polymers USA: Declared Feb. 15 on polypropylene

**OQ Chemicals: Declared Feb. 15 on US oxo-alcohols, aldehydes, acids and esters produced at its Bat City, Texas, operations

SHUTDOWNS

**Chevron Phillips Chemical: three crackers with a combined capacity of 1.36 million mt/year, Sweeny, Texas

**Westlake Chemical: 331,763 mt/year cracker, 249,475 mt/year chlorine, 274,423 mt/year caustic soda, 680,388 mt/year VCM, 680,388 mt/year PVC, Calvert City, Kentucky

**Eastman Chemical: 730,000 mt/year ethylene capacity, Longview, Texas

**INEOS: 1.89 million mt/year of ethylene capacity, Chocolate Bayou, Texas

**LyondellBasell: 2.29 million mt/year of ethylene capacity in La Porte and Corpus Christi, Texas

**Total: 1.15 million mt/year PP, La Porte, Texas

**Lotte Chemical: 700,000 mt/year MEG, 1 million mt/year joint-venture cracker, Lake Charles, Louisiana

**Braskem: 225,000 mt/year PP, Seadrift, Texas

**ExxonMobil: Cumulative 1.53 million mt/year from three units, HDPE and LLDPE capacity, Mont Belvieu, Texas

**Indorama Ventures: 1 million mt/year ethylene oxide/MEG unit, 238,135 mt/year propylene oxide unit, and 988,000 mt/year of MTBE capacity; Clear Lake, Texas, 435,000 mt/year EO, 358,000 mt/year MEG; Port Neches, Texas

**Olin: Freeport, Texas complex, with 3 million mt/year of caustic soda and 2.73 million mt/year of chlorine capacity; 748,000 mt/year of EDC

**OxyChem: Ingleside, Texas, 544,000 mt/year cracker; 248,000 mt/year chlor-alkali; 680,000 mt/year EDC; Deer Park and Pasadena, Texas, 1.27 million mt in PVC capacity; 1.79 million mt/year of VCM capacity; 580,000 mt/year chlor-alkali

**Shintech: Freeport, Texas: 1.45 million mt/year PVC

**Formosa Plastics USA: Point Comfort, Texas, including three crackers with a cumulative capacity of 2.76 million mt/year; 875,000 mt/year of high density polyethylene; 400,000 mt/year of low density PE; 465,000 mt/year of linear low density PE; 798,000 mt/year of PVC; 1 million mt/year of caustic soda and 910,000 mt/year of chlorine; 753,000 mt/year of VCM; 1.478 million mt/year of EDC; and a cumulative 1.17 million mt/year of MEG operated by sister company Nan Ya Plastics.

**Dow Chemical: Certain units offline within Dow sites along the US Gulf Coast, but the company did not specify. Dow’s Gulf Coast operations include two LDPE units with 552,000 mt/year and 186,000 mt/year HDPE; Dow’s Seadrift, Texas, complex includes 490,000 mt/year LLDPE and 390,000 mt/year HDPE; Dow told South American customers in a letter dated Feb. 16 that the company was assessing impact on PE production capacity “and we know that our ability to supply various products could be affected.”

**Dow Chemical: 998,000 mt/year cracker, Freeport, Texas

**TPC Group: Houston site, including 544,310 mt/year butadiene unit, when boilers lost steam

**CP Chem: Pasadena, Texas, 998,000 mt/year HDPE

**CP Chem: 853,000 mt/year cracker, Port Arthur, Texas

**Westlake Chemical: 632,000 mt/year cracker, Lake Charles, Louisiana

RESTARTS

**MEGlobal: 750,000 mt/year MEG plant, Freeport, Texas

**Formosa Plastics USA: restarting PP production at Point Comfort, Texas, complex; has two PP units with combined capacity of 1.7 million mt/year

**Shell: Restarting two crackers with a combined 961,000 mt/year of capacity, Deer Park, Texas

**OxyChem/Orbia: Restarting 550,000 mt/year cracker, Ingleside, Texas

**LyondellBasell: Restarting two crackers with a combined 1.93 million mt/year of capacity, Channelview, Texas

**CP Chem: Restarting two crackers with a combined 1.9 million mt/year of capacity, Cedar Bayou, Texas

**CP Chem: Restarting 853,000 mt/year cracker, Port Arthur, Texas

**Indorama Ventures: Restarting 235,867 mt/year cracker, Port Neches, Texas

**Dow Chemical: Restarting 680,000 mt/year cracker, Freeport, Texas

**Braskem: 360,000 mt/year PP Freeport, Texas; 400,000 mt/year PP, La Porte, Texas

**Motiva Chemicals: Restarted 635,000 mt/year mixed-feed cracker, Port Arthur, Texas

**Shell: Norco, Louisiana, restarted two crackers with a combined 1.4 million mt/year of capacity

**Baystar Polymers: Restarting 408,000 mt/year HDPE unit at Bayport, Texas

**Flint Hills Resources: Restarting 658,000 mt/year PDH unit, Houston

**Dow Chemical: Restarting 750,000 PDH, Freeport, Texas

**Braskem: Restarting 450,000 mt/year PP, La Porte, Texas

**Dow Chemical: Restarted 680,000 mt/year cracker in Orange, Texas

**ExxonMobil: Beaumont, Texas, restart activity begun; 826,000 mt/year cracker operational; 225,000 mt/year HDPE; 240,000 mt/year LDPE; 1.19 million mt/year LLDPE with some HDPE capacity

**ExxonMobil: Baytown, Texas, restart activity begun; three crackers with a combined capacity of 3.8 million mt/year; 800,000 mt/year PP

**Sasol: Restarted 380,000 mt/year EO/MEG, Lake Charles, Louisiana

**Formosa Plastics USA: Restarted 513,000 mt/year PVC, 653,000 mt/year VCM, Baton Rouge, Louisiana

**LyondellBasell: Lake Charles, Louisiana, joint-venture 470,000 mt/year LLDPE; 420,000 mt/year LDPE

PRICES

**March and April US spot ethylene prices held for a third consecutive day at 57 cents/lb FD Mont Belvieu and 52.75 cents/lb FD Mont Belvieu, respectively, as producers continued working to restart crackers. However, March and April FD Choctaw markers each rose a 1 cent/lb on the day to 57.50 cents/lb and 53.25 cents/lb, respectively.

**March spot propylene prices extended declines on the day March 4, falling 11 cents/lb to 55.25 cents/lb FD USG, while April propylene fell 10 cents/lb to 49.50 cents/lb FD USG after two of the three US PDH plants restarted post-freeze.

— Kristen Hays, kristen.hays@spglobal.com

https://www.spglobal.com/platts/en/products-services/electric-power/gas-and-power

March 5, 2021

Stunning Views Of Freight Train Derailment In California Desert

by Tyler DurdenThursday, Mar 04, 2021 – 20:00

On Wednesday evening, a freight train derailment in the Southern California desert sent more than 40 railcars careening off the tracks into a mangled mess of metal.

San Bernardino County Fire (SBCF) tweeted pictures and a drone video of the train derailment. They said the incident occurred on the Burlington Northern Santa Fe Railway Company (BNSF Railway) rail network east of Ludlow, on Old National Trails Highway, or about 150 miles northeast of Los Angeles.

SBCF said, “BNSF cargo railcars, no injuries, no fire, Haz-Mat on scene. No impact to I-40.” Judging by the pictures released by the local police agency, a variety of cars were involved in the incident, including tanker cars, boxcars, and hoppers.

Mixed Freight Derailment

Tanker Cars And Other Cars Derailed

More Scenes Of The Incident

A drone video shows first responders in hazmat suits inspecting a tanker car.

The police drone captured stunning views of the mangled railcars.

“Initial reports indicate 44 cars derailed, and one car carrying ethanol alcohol is leaking,” BNSF spokeswoman Lena Kent told NBC Los Angeles.

Investigators are still working the incident area to figure out how the derailment occurred.

March 5, 2021

Stunning Views Of Freight Train Derailment In California Desert

by Tyler DurdenThursday, Mar 04, 2021 – 20:00

On Wednesday evening, a freight train derailment in the Southern California desert sent more than 40 railcars careening off the tracks into a mangled mess of metal.

San Bernardino County Fire (SBCF) tweeted pictures and a drone video of the train derailment. They said the incident occurred on the Burlington Northern Santa Fe Railway Company (BNSF Railway) rail network east of Ludlow, on Old National Trails Highway, or about 150 miles northeast of Los Angeles.

SBCF said, “BNSF cargo railcars, no injuries, no fire, Haz-Mat on scene. No impact to I-40.” Judging by the pictures released by the local police agency, a variety of cars were involved in the incident, including tanker cars, boxcars, and hoppers.

Mixed Freight Derailment

Tanker Cars And Other Cars Derailed

More Scenes Of The Incident

A drone video shows first responders in hazmat suits inspecting a tanker car.

The police drone captured stunning views of the mangled railcars.

“Initial reports indicate 44 cars derailed, and one car carrying ethanol alcohol is leaking,” BNSF spokeswoman Lena Kent told NBC Los Angeles.

Investigators are still working the incident area to figure out how the derailment occurred.

Texas “Deep Freeze” Opens the Door for Appalachian Basin Investment

Tuesday, March 2nd 2021, 8:13 AM ESTS

PENN VALLEY, PA, U.S., March 2, 2021 /EINPresswire.com/ — The physical and mental misery throughout Texas due to the “Big Freeze” plus snow, and the attendant spike in energy prices nationwide is not yet over.

Well-below freezing temperatures and snow did much more than freeze pipelines, ice over wind turbines and cover solar panels.

Much of the U.S. petrochemical industry is centered along the Gulf Coast and, like their refinery cousins, petchem complexes were shut down, froze up, lost power, etc.

While several petchem giants have announced the restart of their facilities, a few factors have converged which could make returning to production impossible.

“The impact of the COVID pandemic, last summer’s very active hurricane season and now the Big Freeze have combined and will lead to a big shock for consumers,” according to Tom Gellrich, founder of TopLine Analytics.

The shock will be due to shortages, Gellrich said, as many of the plastic types we take for granted, used for such everyday things as milk jugs, hydrogen peroxide, even the numerous volume of plastic incorporated in today’s vehicles, could be in short supply.

Gellrich will further explain how the Texas Big Freeze could open the door to increased petchem investment in the Appalachian Basin at the Second Annual Appalachian Basin Real Estate Conference.

Presented by Shale Directories, the one-day program is slated for March 25, at the Oglebay Resort in Wheeling, West Virginia.

“Tom’s presentation will vividly demonstrate the petrochemical opportunity in the Appalachian Basin is now,” commented Joe Barone, President & Founder, Shale Directories.

Gellrich said the need for plastics related to treating COVID for such things as personal protective equipment (PPE), and hurricane-related flooding which shut petchem plants, led to a sharp drawdown in inventory.

“And now, you have the Big Freeze, which further strains inventories,” Gellrich said.

For chemical producers restarting their complexes, Gellrich said the time needed to do a restart is three weeks minimum, as all equipment must be pulled apart and inspected.

“Employees will need to work overtime, and more outside contractors will be needed to do the job,” he said. And keep in mind, many of these workers have their owns problems at home, with broken pipes, no electricity, etc., which also must be addressed.”

If plant components must be replaced, Gellrich said needed components may not be available. “Every part of the supply chain is so connected today that if one piece of equipment must be replaced, there is a ripple effect throughout the entire chain,” according to Gellrich.

“We might be three months out before things are back to normal.”

The hardships caused by COVID, hurricanes and the Texas Big Freeze are forcing numerous companies, analysts and consultants to take a closer look at supply chains, bringing more chain components back to the U.S. from China and other overseas venues.

“Some companies will look at other locations other than the Gulf Coast to establish petrochemical facilities,” said Gellrich.

The logical region to serve as the U.S.’s Petrochemical Hub No. 2 would be the Appalachian Basin, as it offers inexpensive natural gas for fuel/feedstock and is located within 700 miles of numerous plastic products wholesalers and customers.

Joseph Barone

Shale Directories

+1 610-764-1232

jbarone@shaledirectories.com

First Oil Discoveries

A Pennsylvania oil well in 1859 fueled kerosene lamps. A 1901 gusher in Texas would fuel autos.

The American Oil & Gas Historical Society frequently updates AOGHS.ORG content with new articles as part of its energy education mission. The society maintains a communication network of petroleum museums, teacher workshop programs, county historical societies, and similar organizations.

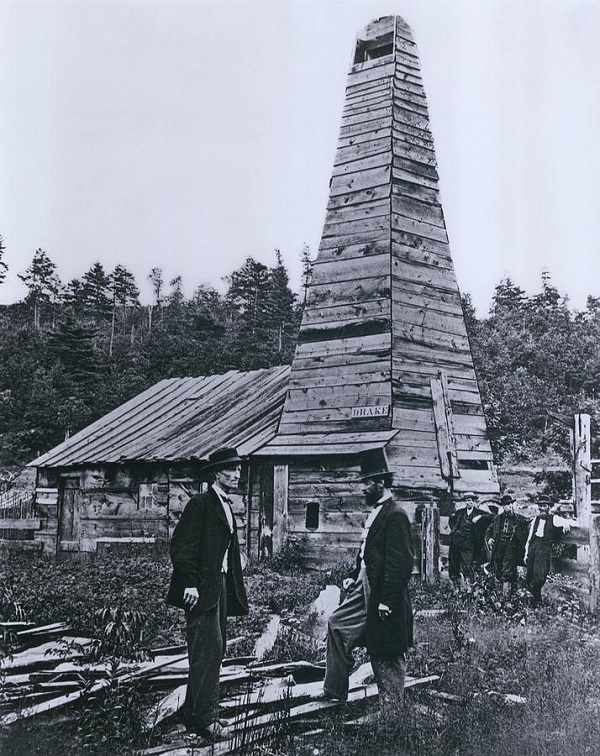

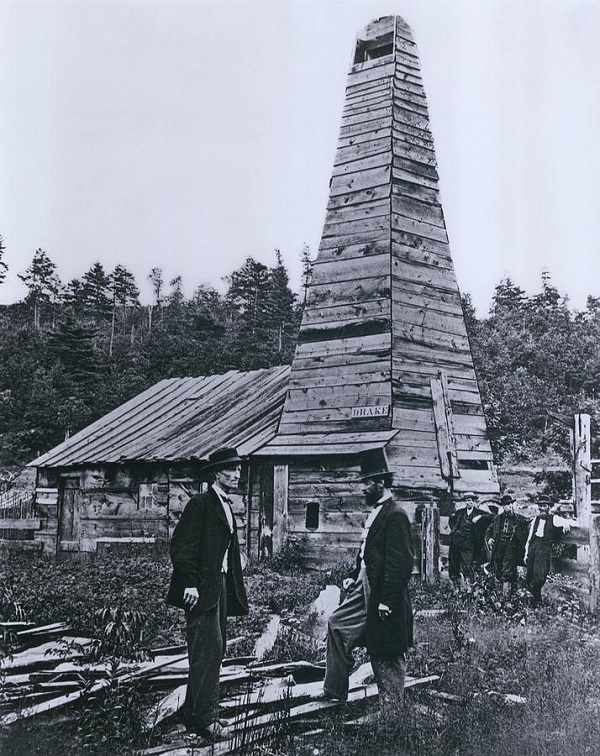

Edwin Drake, right, stands with friend Peter Wilson of Titusville, Pennsylvania, at the drilling site – but not the original cable-tool derrick – of America’s first oil well. Photo courtesy Drake Well Museum.

To help preserve U.S. petroleum history, the society documents exploration, production, and transportation milestones. It also tells the many stories of generations of “oil patch” families. Contact the society with your suggestions for articles, comments – and much-needed financial support.

Birth of the U.S. Oil and Natural Gas Industry

The domestic petroleum industry that began in 1859 with a well drilled just 69.5 feet deep forever changed America’s economy, standard of living, and culture. The earliest exploration companies began seeking oil for refining into a newly invented lamp fuel called kerosene. This “rock oil” fuel was cheaper than whale oil, and far safer than the more popular but explosive fuel, camphene.

As more states joined Pennsylvania in becoming “producing states,” the political landscape changed as fast as exploration technologies. Early energy issues included need for an infrastructure for producing, storing, and transporting oil and natural gas. As discoveries grew, the rush for “black gold” resulted in complex economic issues on a national scale, including wasteful over-production, sudden collapses of oil prices, questionable stock promotions, and frequent boom-and-bust cycles.

The industry also faced a major challenge just as the improved science of petroleum geology began finding mid-continent oilfields. Thomas Edison invented the first commercially practical incandescent light in 1879, threatening the oil industry’s principle product, kerosene. Demand would continue for other refined products (see vaseline and axle-grease). Fortunately for exploration and production companies, automobiles powered by an internal combustion engine required what had been a refinery byproduct: gasoline. The first U.S. auto show took place inside New York City’s Madison Square Garden in November 1900. Less than two months later, an oil gusher at Spindletop, Texas, launched the modern U.S. oil industry. The coming century would bring far greater challenges for petroleum and the world.

First American Oil Well

American oil history begins in a woodland valley along a creek in remote northwestern Pennsylvania. Today’s U.S. petroleum exploration and production industry is born on August 27, 1859, near Titusville when a well specifically drilled for oil finds it. A former railroad conductor drilled it for New Haven Connecticut investors. Even more early petroleum history came on the banks of Oil Creek: First Oil Well, First Oil Well Fire.

Spindletop launches Modern Petroleum Industry

The 1901 “Lucas Gusher” in Texas reveals the Spindletop oilfield, which will produce more oil in one day than the rest of the world’s oil fields combined. The Prophet of Spindletop – self-taught geologist Patillo Higgins – had founded the Gladys City Oil, Gas & Manufacturing Company in 1892 near Beaumont, Texas.

Texas “Deep Freeze” Opens the Door for Appalachian Basin Investment

Tuesday, March 2nd 2021, 8:13 AM ESTS

PENN VALLEY, PA, U.S., March 2, 2021 /EINPresswire.com/ — The physical and mental misery throughout Texas due to the “Big Freeze” plus snow, and the attendant spike in energy prices nationwide is not yet over.

Well-below freezing temperatures and snow did much more than freeze pipelines, ice over wind turbines and cover solar panels.

Much of the U.S. petrochemical industry is centered along the Gulf Coast and, like their refinery cousins, petchem complexes were shut down, froze up, lost power, etc.

While several petchem giants have announced the restart of their facilities, a few factors have converged which could make returning to production impossible.

“The impact of the COVID pandemic, last summer’s very active hurricane season and now the Big Freeze have combined and will lead to a big shock for consumers,” according to Tom Gellrich, founder of TopLine Analytics.

The shock will be due to shortages, Gellrich said, as many of the plastic types we take for granted, used for such everyday things as milk jugs, hydrogen peroxide, even the numerous volume of plastic incorporated in today’s vehicles, could be in short supply.

Gellrich will further explain how the Texas Big Freeze could open the door to increased petchem investment in the Appalachian Basin at the Second Annual Appalachian Basin Real Estate Conference.

Presented by Shale Directories, the one-day program is slated for March 25, at the Oglebay Resort in Wheeling, West Virginia.

“Tom’s presentation will vividly demonstrate the petrochemical opportunity in the Appalachian Basin is now,” commented Joe Barone, President & Founder, Shale Directories.

Gellrich said the need for plastics related to treating COVID for such things as personal protective equipment (PPE), and hurricane-related flooding which shut petchem plants, led to a sharp drawdown in inventory.

“And now, you have the Big Freeze, which further strains inventories,” Gellrich said.

For chemical producers restarting their complexes, Gellrich said the time needed to do a restart is three weeks minimum, as all equipment must be pulled apart and inspected.

“Employees will need to work overtime, and more outside contractors will be needed to do the job,” he said. And keep in mind, many of these workers have their owns problems at home, with broken pipes, no electricity, etc., which also must be addressed.”

If plant components must be replaced, Gellrich said needed components may not be available. “Every part of the supply chain is so connected today that if one piece of equipment must be replaced, there is a ripple effect throughout the entire chain,” according to Gellrich.

“We might be three months out before things are back to normal.”

The hardships caused by COVID, hurricanes and the Texas Big Freeze are forcing numerous companies, analysts and consultants to take a closer look at supply chains, bringing more chain components back to the U.S. from China and other overseas venues.

“Some companies will look at other locations other than the Gulf Coast to establish petrochemical facilities,” said Gellrich.

The logical region to serve as the U.S.’s Petrochemical Hub No. 2 would be the Appalachian Basin, as it offers inexpensive natural gas for fuel/feedstock and is located within 700 miles of numerous plastic products wholesalers and customers.

Joseph Barone

Shale Directories

+1 610-764-1232

jbarone@shaledirectories.com

First Oil Discoveries

A Pennsylvania oil well in 1859 fueled kerosene lamps. A 1901 gusher in Texas would fuel autos.

The American Oil & Gas Historical Society frequently updates AOGHS.ORG content with new articles as part of its energy education mission. The society maintains a communication network of petroleum museums, teacher workshop programs, county historical societies, and similar organizations.

Edwin Drake, right, stands with friend Peter Wilson of Titusville, Pennsylvania, at the drilling site – but not the original cable-tool derrick – of America’s first oil well. Photo courtesy Drake Well Museum.

To help preserve U.S. petroleum history, the society documents exploration, production, and transportation milestones. It also tells the many stories of generations of “oil patch” families. Contact the society with your suggestions for articles, comments – and much-needed financial support.

Birth of the U.S. Oil and Natural Gas Industry

The domestic petroleum industry that began in 1859 with a well drilled just 69.5 feet deep forever changed America’s economy, standard of living, and culture. The earliest exploration companies began seeking oil for refining into a newly invented lamp fuel called kerosene. This “rock oil” fuel was cheaper than whale oil, and far safer than the more popular but explosive fuel, camphene.

As more states joined Pennsylvania in becoming “producing states,” the political landscape changed as fast as exploration technologies. Early energy issues included need for an infrastructure for producing, storing, and transporting oil and natural gas. As discoveries grew, the rush for “black gold” resulted in complex economic issues on a national scale, including wasteful over-production, sudden collapses of oil prices, questionable stock promotions, and frequent boom-and-bust cycles.

The industry also faced a major challenge just as the improved science of petroleum geology began finding mid-continent oilfields. Thomas Edison invented the first commercially practical incandescent light in 1879, threatening the oil industry’s principle product, kerosene. Demand would continue for other refined products (see vaseline and axle-grease). Fortunately for exploration and production companies, automobiles powered by an internal combustion engine required what had been a refinery byproduct: gasoline. The first U.S. auto show took place inside New York City’s Madison Square Garden in November 1900. Less than two months later, an oil gusher at Spindletop, Texas, launched the modern U.S. oil industry. The coming century would bring far greater challenges for petroleum and the world.

First American Oil Well

American oil history begins in a woodland valley along a creek in remote northwestern Pennsylvania. Today’s U.S. petroleum exploration and production industry is born on August 27, 1859, near Titusville when a well specifically drilled for oil finds it. A former railroad conductor drilled it for New Haven Connecticut investors. Even more early petroleum history came on the banks of Oil Creek: First Oil Well, First Oil Well Fire.

Spindletop launches Modern Petroleum Industry

The 1901 “Lucas Gusher” in Texas reveals the Spindletop oilfield, which will produce more oil in one day than the rest of the world’s oil fields combined. The Prophet of Spindletop – self-taught geologist Patillo Higgins – had founded the Gladys City Oil, Gas & Manufacturing Company in 1892 near Beaumont, Texas.