The Urethane Blog

Everchem Updates

VOLUME XXI

September 14, 2023

Everchem’s exclusive Closers Only Club is reserved for only the highest caliber brass-baller salesmen in the chemical industry. Watch the hype video and be introduced to the top of the league: — read more

When we lose business to a better player, do we take it personally? Don Draper from Mad Men wouldn’t take it personally. He would study hard to find what exactly blew the deal, get blackout drunk on bourbon on a few days’ bender at the public house, and the next week hatch himself a revised plan of conquest and redemption. Let’s bring that energy back.

Subscribe to the Urethane blog for more Everchem Updates here

May 31, 2023

Apollo’s Top Economist Says Supply Chain Roller Coaster Over

by Tyler Durden

Wednesday, May 31, 2023 – 03:45 PM

According to a new report from Apollo’s chief economist Torsten Sløk, the global supply chain crisis appears to be over, as there are indications of normalization in shipping rates, delivery capacity, and retailer inventory.

Sløk presents a chart pack that shows the supply chain roller coaster ride of the last three years is over. He shared several charts showing cheaper shipping costs and fewer bottlenecks, which might support disinflation trends.

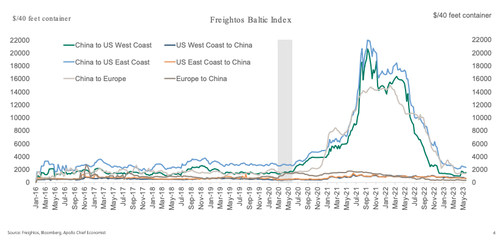

Price of transporting a container from China at pre-pandemic levels

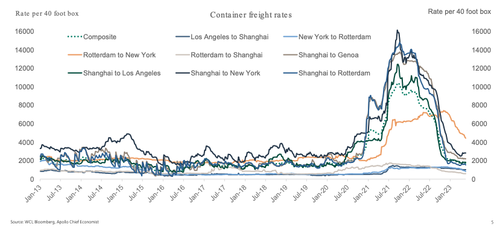

Container freight rates falling: Inflation pressures are easing

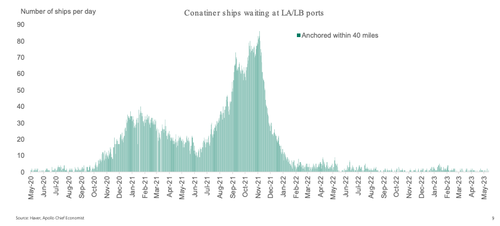

Container ships at America’s largest ports return to pre-pandemic levels

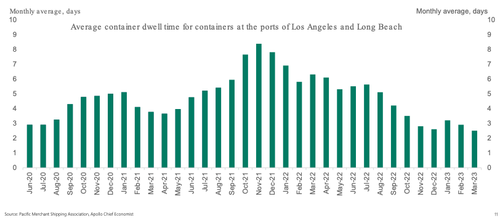

Amount of time a container waits to get picked up at a marine terminal after being unloaded from a vessel

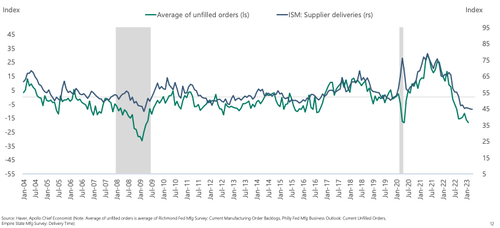

Supply chains have normalized

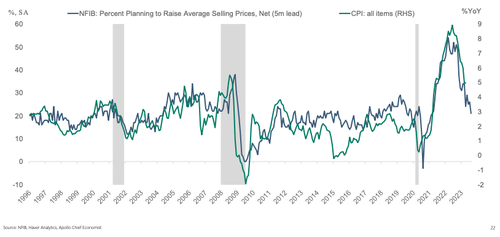

Sløk then argues supply chain normalization has put downward pressure on inflation.

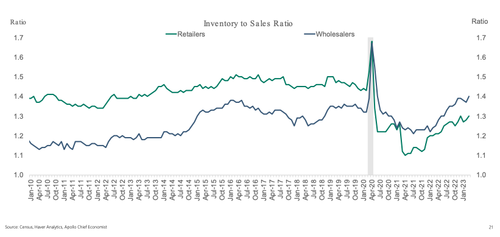

Inventory to sales ratio normalizing

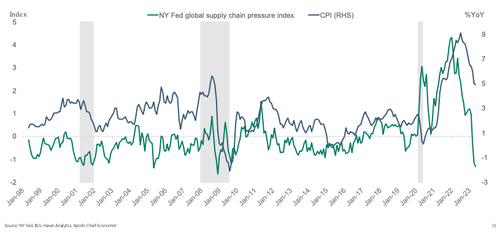

Inflation pressures are gradually easing

More evidence of supply chain normalization puts downward pressure on inflation

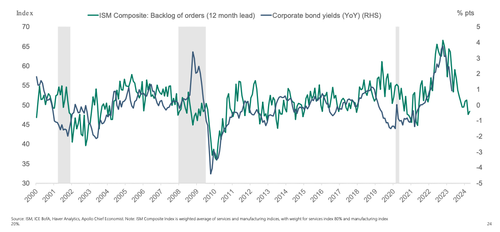

Supply chain bottlenecks correlated with corporate bond yields

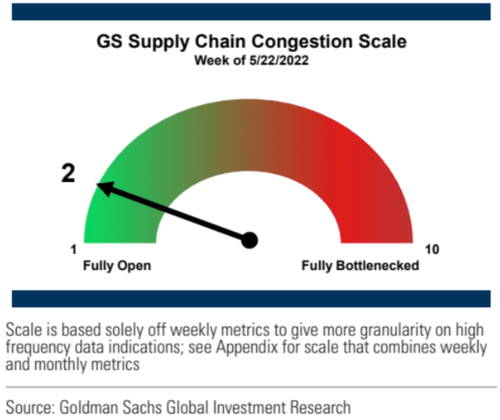

Sløk’s chart pack aligns with Goldman Sachs’ latest data on tracking supply chains showing barely any congestion.

Considering the importance of supply chains, its return to normalcy is more positive news that could help subdue inflation.

In terms of what’s next, A.P. Moller-Maersk A/S, the world’s biggest shipping company, issued a warning several weeks ago about a potential global slowdown.

https://www.zerohedge.com/markets/apollos-top-economist-says-supply-chain-roller-coaster-over

May 30, 2023

$0.385/lb . . .

CertiPUR-US® Program Adds Michigan-Based

Enthalpy Analytical as Approved Laboratory

Enthalpy Analytical in Mount Pleasant, Michigan, becomes fourth laboratory

authorized to test foams to meet CertiPUR-US® program requirements

(Rochester Hills, Mich. – May 30, 2023) The CertiPUR-US® foam certification program has approved its fourth testing laboratory for CertiPUR-US® certification of flexible polyurethane foam for use in upholstered furniture and bedding.

Following a rigorous selection and approval process that has spanned more than two years, Enthalpy Analytical has been approved by the Alliance for Flexible Polyurethane Foam’s CertiPUR-US Board of Directors to conduct the content analysis and emissions testing to determine if submitted foams meet the certification program’s requirements as outlined in the program’s Technical Guidelines.

Few labs have the equipment and capacity to do all the testing required, which is one of the conditions for being an approved lab.

“Enthalpy was thoroughly vetted by our board and our Technical Advisory Group and, in addition to having the required equipment, had to pass round-robin testing with sample foams to show results matched results of other approved labs on identical foams,” explained Michael Crowell, CertiPUR-US executive director.

“We are pleased to join the CertiPUR-US program as an approved laboratory,” said Sarah Mack, business development manager for Enthalpy Analytical. Mack elaborated: “We have seen environmental and sustainability initiatives focus on and continue to promote accountability programs such as this and are proud to actively support this important work. It is an honor to assist organizations with their goal of protecting consumers and is a direct complement to our mission to protect the air we breathe, the water we drink, and the soil that feeds us!”

Only one other lab that is approved for testing compliance with the CertiPUR-US program requirements is located in the U.S. Other labs are located in Denmark and Germany. There are now four approved labs worldwide and listed at www.certipur.us/labs.

“We are very pleased to welcome this highly regarded company with a solid reputation,” said Crowell. “Adding another U.S.-based testing facility provides more choices for the more than 90 foam producers participating in the program and certifying more than 200 foam families on an annual basis.”

Certified flexible polyurethane foam products are analyzed by these independent, accredited testing laboratories and are certified to be made without ozone depleters, made without lead and heavy metals, made without formaldehyde, made without phthalates regulated by the Consumer Product Safety Commission and screened for relevant chemicals (including flame retardants) classified as carcinogenic, mutagenic or reprotoxic (see Technical Guidelines at certipur.us/technicalguidelines for details). Foams are also tested for emissions and must be low VOC (Volatile Organic Compound) emissions for indoor air quality (less than 0.5 parts per million).

In addition to foam producers submitting foams for testing, the CertiPUR-US program itself uses the approved labs to conduct testing of foam samples acquired through random on-site foam production plant checks of participating producers.

Enthalpy Analytical LLC is a wholly owned subsidiary of Montrose Environmental Group Inc., providing environmental laboratory services as part of Montrose’s Measurement and Analysis division. Enthalpy operates a network of accredited laboratories across the U.S. Within the network, Enthalpy has laboratories that specialize in analysis of air, soil, water and sediment.

# # #

May 29, 2023

Will Shutdown of Dow’s PO Plant in U.S. Change Asian Trade Flow?

PUdaily | Updated: May 29, 2023

The end-users of propylene oxide (PO) include industries such as real estate, automobiles, furniture, refrigerators, and freezers, which are closely related to the development of the national economy. An increase in demand for polyurethane due to the rise in the prosperity of these industries will stimulate polyols suppliers to increase production, thereby increasing the demand for PO and driving up prices.

On May 16, it was reported that Dow Chemical plans to close its PO plant in Freeport, Texas, by the end of 2025.

The decision to close the PO plant arose from the fact that the plant is approaching its end-of-life, and the overall chemical industry is not prosperous due to the slowing global economic growth and various uncontrollable factors. The demand from most end-users is weakening, and polyurethane suppliers are paying more attention to higher value-added segments. Therefore, the decision to close the plant is part of Dow Chemical’s efforts to optimize costs and supply conditions.

Dow’s PO plant in Freeport will continue to operate until the end of 2025, while downstream polyether polyol plants will continue to operate after the PO plant is shut down. After 2025, Dow will use resources from other regions or third-party suppliers to supply PO to its polyol plants. Dow is also investing in logistics capabilities, such as PO tanks, pipelines, and new barges to ensure the normal supply.

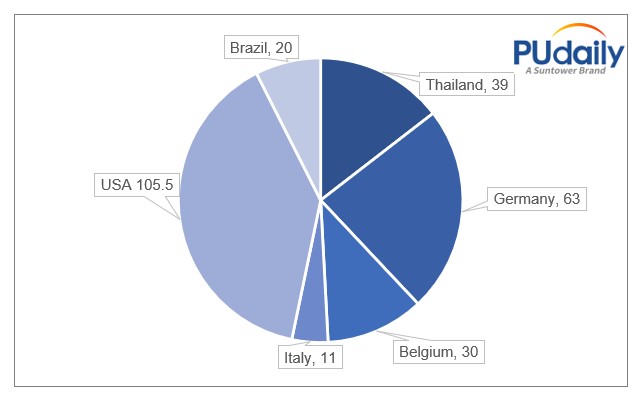

Currently, Dow Chemical is the world’s largest PO producer with an extensive layout of plants in the U.S., Germany, Brazil, Belgium, and Thailand. Its total capacity is 2.685 mtpa, contributing 20.24% of the global PO output.

Dow Chemical’s PO Capacity Layout (10kT)

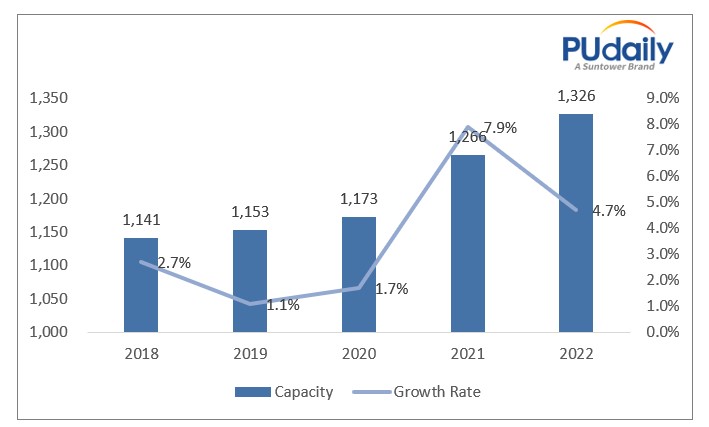

Global PO Capacity & YoY Changes, 2018-2022 (10kT, %)

Dow’s PO production uses the chlorohydrin process technology. The patent owners of the chlorohydrin process are mainly Dow in U.S., Asahi Glass, Mitsui Toatsu and Showa Denko in Japan. The chlorohydrin process was industrialized as early as 1931 and has the advantages of mature technology, short process, low purity requirements for raw materials, and low investment. The key of this technology is the chlorohydrin reactor, and Dow Chemical’s tubular reactor is representative of the chlorohydrin process.

But the chlorohydrin process causes severe environmental pollution, and under the background of increasingly stringent environmental regulations, the use of chlorohydrin technology faces enormous challenges. The US government has already eliminated chlorohydrin technology in 2000, and China has also listed chlorohydrin process as a restricted item in the Guidance Catalogue for Industrial Structure Adjustment (2011), and new facilities cannot adopt this technology.

The shutdown of Dow’s PO plant in the U.S. will cause a supply gap. Part of the gap will be filled by LyondellBasell (In March of this year, LyondellBasell successfully started up the world’s largest PO and TBA plant in Texas. These new assets on the U.S. Gulf Coast have an annual capacity of 470,000 tonnes of PO and 1 million tonnes of TBA and its derivatives). Some PO suppliers in countries such as South Korea, Saudi Arabia, and Thailand will also increase exports to the U.S. China’s PO export is constrained by process requirements and lack of export tax refunds. The tax rebate rate for downstream products of PO, such as polyether polyols, propylene glycol, and propylene glycol methyl ether, has been increased to 13%, further enhancing their export competitiveness.