The Urethane Blog

Everchem Updates

VOLUME XXI

September 14, 2023

Everchem’s exclusive Closers Only Club is reserved for only the highest caliber brass-baller salesmen in the chemical industry. Watch the hype video and be introduced to the top of the league: — read more

March 28, 2023

New Home Sales Unexpectedly ‘Rose’ In February, Median Price Rebounds

by Tyler Durden

Thursday, Mar 23, 2023 – 10:09 AM

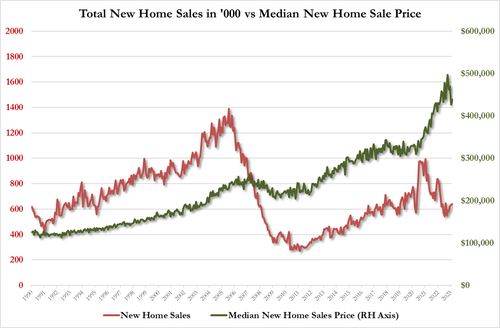

After surging far more than expected in December and January (and beaten expectations in each of the last six months), new home sales were expected to slide in February (despite the unexpected jump in existing home sales as mortgage rates took a pause from their blast off higher). However, like existing home sales, new home sales rose 1.1% MoM (-3.1% exp). This is the seventh beat in a row, but only because January’s +7.2% MoM spike was revised dramatically lower to a mere +1.8% MoM… if that January level had held this would have been a 4.5% MoM drop…

Source: Bloomberg

Year-over-year, new home sales remain down 19%, but on a SAAR basis are back near their highest since last April…

Source: Bloomberg

Sales rose in the West and South, the two largest regions by purchases. The number of homes sold in the Northeast plunged to the lowest since June.

The median home price rose from $426.5K (lowest since Sept Dec 21) to $438.2K…

Supply continues to contract (some might say ‘normalize’). There were 436,000 new homes for sale as of the end of last month, the lowest since April. That represents 8.2 months of supply at the current sales rate. …

Source: Bloomberg

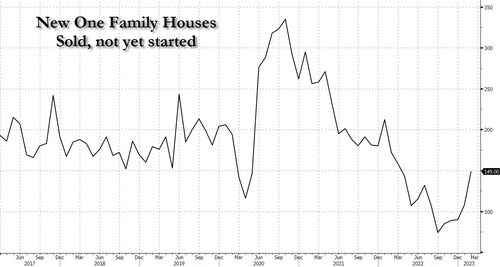

Interestingly, the number of homes sold, but not yet started, continues to rise, surging to 149K, from 108K, the highest since March 2022…

Source: Bloomberg

Of course, the problem is, mortgage rates have resurged back above 7.00% since this data…

Source: Bloomberg

Resurgent home sales (and prices) is not what Powell wants to see – don’t expect mortgage rates to save any homebuyers anytime soon (especially as banks tighten lending standards amid a liquidity/solvency crisis).

March 28, 2023

Mitsui Chemicals : to Optimize TDI Production Capacity

03/28/2023 | 12:48am EDT

2023.03.28

Mitsui Chemicals, Inc.

Mitsui Chemicals, Inc. (Tokyo: 4183; President & CEO: HASHIMOTO Osamu) today announced plans to optimize the production capacity of its Omuta Works’ toluene diisocyanate (TDI) plant in July 2025. TDI is used as a raw material in the production of polyurethane.

1. Objectives and Background

Mitsui Chemicals currently manufactures and sells TDI (Production capacity 120,000 tons per annual) for use as a basic material in the isocyanate chain at the Omuta Works. However, given supply and demand trends in Japan and overseas, Mitsui Chemicals has decided that a reduced output of around 50,000 tons per year will be optimal going forward.

While maintaining a stable supply setup to meet domestic demand for TDI, the Omuta Works will contribute to expansion in growth domains as part of Mitsui Chemicals’ business portfolio transformation by bolstering competitiveness as the company’s principal center for the manufacture of high-performance products, including ophthalmic lens materials and agrochemical products. 【Overview of the TDI plant】

| Manufacturing facility | Mitsui Chemicals Omuta Works (https://jp.mitsuichemicals.com/en/corporate/ds/works.htm) |

| Production capacity | 120,000 tons/year (currently) → around 50,000 tons/year (following optimization) |

| Timing | Planned for July 2025 |

The TDI plant in Omuta Works 2. Future of the Polyurethane Business

As part of its VISION 2030 Long-Term Business Plan, Mitsui Chemicals positioned polyurethane as one of several businesses in the Basic & Green Materials Business Sector that would be subject to restructuring.

In addition to the forthcoming optimization of TDI production capacity, the restructure will encompass the development of high value-added products, including high-performance methylene diphenyl diisocyanate and high-performance polyols such as polypropylene glycol. Pursuing these efforts will allow Mitsui Chemicals to reduce earnings volatility, improve capital investment efficiency and lay the business foundations for generating stable earnings.

Mitsui Chemicals also intends to bring about a circular economy transformation by setting up a chemical recycling scheme for polyurethane foam and considering the use of ISCC PLUS-certified bio-based toluene produced at the Osaka Works to manufacture greener TDI.

March 27, 2023

Newest low-water ship now in operation

23.03.2023

HKG Shipping (Cologne) and materials manufacturer Covestro commissioned a new low-water vessel earlier this month. “Courage” is to supply Covestro’s customers with finished products from its sites in North Rhine-Westphalia with immediate effect.

The identically constructed sister ship “Curiosity” will be delivered in a few weeks’ time. At the beginning of May 2023, HGK Shipping and Covestro plan to celebrate the addition to the fleet with a double christening ceremony.

March 22, 2023

Pearl Polyurethane Systems announces major

new Saudi Arabian production facility in Jeddah

Pearl Polyurethane Systems, the award-winning PU system house, has announced the commissioning

of a major new production facility in Jeddah, Saudi Arabia, further reinforcing the company’s industry-

leading position as the largest supplier of polyurethane formulations in the Middle East and Africa

region. Creating new job opportunities in Jeddah, the dedicated plant and office will accommodate

the company’s growing team while further expanding its presence in the Kingdom. With this new

facility, Pearl is accelerating the implementation of its PearlX2 growth plan set to double the

company’s size over the coming five-year period.

Jeddah was chosen as the site for the new Pearl production plant due to its proximity to the city’s

major international port, access to top talent, and excellent transport connections across the

Kingdom.

The new facility will contribute to strengthening Saudi Arabia’s position as a growing manufacturing

hub, with Pearl’s new plant producing polyurethane formulations and high-performance

polyurethane foams widely used in building insulation products, manufacturing processes, and a

range of other everyday applications. Furthermore, the new production facility will leverage Jeddah’s

strong position as an export hub catering to further demand from across the wider region.

Investment into Pearl’s new Jeddah production plant also marks a significant step for the company in

reaffirming its commitment to its existing Saudi-based clients and their vision for the Kingdom to

become a world-class business and tourism destination. Through its clients, Pearl has been working

on multiple projects in Saudi Arabia over the recent years in various fields, including infrastructure,

retail, hospitality, architecture, and the built environment.

Pearl’s expansion in Saudi Arabia is also closely aligned with Vision 2030 national transformation

program objectives, which aim to diversify the Kingdom’s economy and promote private sector

growth. Considering the superior insulation capabilities of rigid polyurethane foams, Pearl’s local

production plant in Jeddah will strongly support the objectives of becoming CO2-neutral by 2060.

“Our roots in Saudi Arabia run deep. Pearl has been servicing clients in the Kingdom for decades and

we are excited about this new production facility commissioning dedicated to providing our Saudi-

based clients with the very best delivery options possible and industry-leading innovation, while

ensuring supply chain resilience. The new Jeddah facility, coupled with investment and growth in our

other offices and facilities across the MENA region, will enable Pearl to maintain world-class service

delivery standards and respond to evolving customer demands across several product areas,” said

Martin Kruczinna, CEO of Pearl Polyurethane Systems. “We are thrilled to offer our Saudi clients the

benefit of dedicated production and warehousing facilities in the Kingdom as well as the type of

personalised, customer-centric service that our international clients have become accustomed to over

the past 35 years.

“This investment represents another tremendous show of confidence in the growing strength and

significance of the Saudi Arabian economy and our company’s close alignment with Vision 2030 goals.

Focusing on building and infrastructure insulation solutions, as well as consumer goods such as

appliances and footwear together with a range of other products, our new production facility ensures

that we continue to offer best-in-class PU solutions to our current and new Saudi-based clients,

supporting further manufacturing sector growth in the Kingdom,” concluded Kruczinna.

Pearl’s R&D team won the Innovative Insulation Project of the Year 2021 award for the first R&D

initiative of its type launched in the Middle East, and again in 2022 for launching its new, more

sustainable low lambda insulation product as part of its EcoPearl range, achieving an overall

improvement of up to 20 per cent in insulation performance over comparable products.

Operating since 1989, the company has supplied polyurethane insulation foam systems for several

trailblazing projects in the Gulf region, including Palm Jumeirah, Downtown Dubai, Ski Dubai, and,

more recently, the Germany Pavilion at Dubai Expo 2020 Bustanica, the world’s largest vertical farm

for Emirates Airlines flight catering in Dubai, and Noon’s fulfilment center in Saudi Arabia.

Pearl Polyurethane offers a comprehensive range of polyurethane formulations and prepolymers for

the production of high-performance polyurethane foams and elastomers.

March 21, 2023

Wanhua Chemical posts 34% profits drop in 2022

MOSCOW (MRC) — China’s Wanhua Chemical reported a 34.1% decrease in net profits in 2022, as steep increases in raw materials and energy prices significantly squeezed its margin, the company said.

The company has become the world’s biggest methylene diphenyl diisocyanate (MDI) supplier, with a combined capacity of 3.05m tonne/year as of late 2022.

It is also the world’s third largest toluene diisocyanate (TDI) supplier, with a total compacity of 650,000 tonne/year.

Cost for key raw materials rose heavily. For example, prices of benzene, coal and liquified petroleum gas surged by 14%-21% in 2022.

Its 1m tonne/year ethylene project in Yantai operated at 91% in 2022. Its polyurethane plants’ overall utilisation rate stood at 92% in 2022.

Outlooks: Progress on constructions of its Penglai complex, consisting of a 900,000 tonne/year propane dehydrogenation unit and downstream units. 2023 will be its “project year”. All project investments should follow three rules: in line with the company’s strategy and resources access capacity, having comparatively competitive advantages even in the most extreme competition scenario, with comprehensive considerations of global operating environment.

Wanhua Chemical also plans to increase the capacity of its polycarbonate (PC) plant in Yantai in Shandong province by 140,000 tons per year to 340,000 tons per year. The expansion will be carried out by reengineering the existing 200 ktpa PC production project at the site. The company is currently seeking environmental approval for the plan. The timing of the project is not disclosed.

Wanhua Chemical was founded on December 20, 1998, and is the first listed joint-stock enterprise after reorganization in Shandong Province, China. The company mainly produces diphenylmethane diisocyanate (MDI), including pure MDI and polymerized MDI used in the production of polyurethane (PU).

https://www.mrchub.com/news/406750-wanhua-chemical-posts-34-percent-profits-drop-in-2022