Current Affairs

June 16, 2022

Railroads, Union Negotiations Update

“Ticking Time Bomb” Begins As Major US Railroads, Union Labor Seek Biden Intervention Amid Rail Shutdown Concerns

by Tyler DurdenThursday, Jun 16, 2022 – 05:45 AM

Negotiations between major railroads and their unions have stalled, setting up for what could be a significant railroad shut down before the midterm elections that could paralyze an already-strained US supply chain.

Railway Age reports the National Mediation Board (NMB) on June 14 began what could be a “ticking time bomb” toward a national railroad shut down within 90 days, following its board of three, two Democratic members agreeing with rail labor and NMB’s only Republican disagreeing that means a voluntary agreement to amend unionized rail worker wages, benefits and work rules won’t be achievable.

Talks between rail labor (12 rail craft unions bargaining in two coalitions on behalf of 115k rail workers) and major railroads, including Union Pacific Corp. and BNSF Railway Co., will enter a 30-day cooling period this Friday. Then the Biden administration may appoint a Presidential Emergency Board (PEB) to resolve the dispute.

“The railroads would consider accepting the proffer, but the union leadership has already indicated that it will not,” the National Carriers’ Conference Committee (NCCC), which represents major railroads, said in a statement. “The railroads expect a PEB will be appointed in this dispute before the end of the 30-day cooling-off period, as has been the case in prior unresolved national rail negotiations,” NCCC continued.

Once the PEB is appointed, a second cooling period with a maximum 30-day clock begins. At the same time, the PEB listens to arguments from rail labor and railroads and issues its non-binding recommendations. The third 30-day period is where things could get problematic, just before the elections, and if both parties don’t agree, either side can declare “self-help,” meaning a strike would materialize.

A rail strike would devastate the economy even more, as approximately 28% of freight movement is transported on complex rail networks across the country. Depending on the strike’s duration, supply chains would be further snarled and unleash unwanted inflation.

Let’s hope rail labor and major railroads can agree on wages, benefits, and work rules immediately following the PEB appointment and unions do not resort to a strike in the third 30-day cooling period right before the midterm elections.

June 16, 2022

Railroads, Union Negotiations Update

“Ticking Time Bomb” Begins As Major US Railroads, Union Labor Seek Biden Intervention Amid Rail Shutdown Concerns

by Tyler DurdenThursday, Jun 16, 2022 – 05:45 AM

Negotiations between major railroads and their unions have stalled, setting up for what could be a significant railroad shut down before the midterm elections that could paralyze an already-strained US supply chain.

Railway Age reports the National Mediation Board (NMB) on June 14 began what could be a “ticking time bomb” toward a national railroad shut down within 90 days, following its board of three, two Democratic members agreeing with rail labor and NMB’s only Republican disagreeing that means a voluntary agreement to amend unionized rail worker wages, benefits and work rules won’t be achievable.

Talks between rail labor (12 rail craft unions bargaining in two coalitions on behalf of 115k rail workers) and major railroads, including Union Pacific Corp. and BNSF Railway Co., will enter a 30-day cooling period this Friday. Then the Biden administration may appoint a Presidential Emergency Board (PEB) to resolve the dispute.

“The railroads would consider accepting the proffer, but the union leadership has already indicated that it will not,” the National Carriers’ Conference Committee (NCCC), which represents major railroads, said in a statement. “The railroads expect a PEB will be appointed in this dispute before the end of the 30-day cooling-off period, as has been the case in prior unresolved national rail negotiations,” NCCC continued.

Once the PEB is appointed, a second cooling period with a maximum 30-day clock begins. At the same time, the PEB listens to arguments from rail labor and railroads and issues its non-binding recommendations. The third 30-day period is where things could get problematic, just before the elections, and if both parties don’t agree, either side can declare “self-help,” meaning a strike would materialize.

A rail strike would devastate the economy even more, as approximately 28% of freight movement is transported on complex rail networks across the country. Depending on the strike’s duration, supply chains would be further snarled and unleash unwanted inflation.

Let’s hope rail labor and major railroads can agree on wages, benefits, and work rules immediately following the PEB appointment and unions do not resort to a strike in the third 30-day cooling period right before the midterm elections.

June 10, 2022

Trucking Strike in South Korea

S Korea truckers’ strike to hit Ulsan petrochemical output; halts port ops

Nurluqman Suratman

10-Jun-2022Full storyRelated newsRelated contentContact us SHARE THIS

SINGAPORE (ICIS)–The ongoing nationwide strike by unionised truckers in South Korea are forcing several producers in the petrochemical hub of Ulsan to consider production cuts amid logistics disruption.

Synthetic rubber giant Kumho Petrochemical is expected to slash production rates at its acrylonitrile butadiene styrene (ABS) and polystyrene (PS) units from the second half of June due to the strike, according to market sources.

HDC Hyundai Engineering Plastics Co is also expected to slash production at its 160,000 tonne/year PS plant in the complex.

While there have been no immediate reports of polyethylene (PE) production losses due to the strike, facilities in Ulsan and elsewhere in the country could be affected if the strike drags on.

The strike by the Cargo Truckers Solidarity (CTS) union entered its fourth day on Friday.

Some PE producers may face pressure to sell prompt cargoes or further reduce their cracker run rates owing to the ongoing strike by truckers.

If the transportation problem persists, “I expect more PE plants in South Korea will cutback or shut down in the short term,” ICIS senior analyst Amy Yu said.

The strike has slowed down the delivery of PE cargoes, raising concerns that some producers might have to lower their downstream operation, to manage their already high inventory if the logistic issues continue next week.

“South Korea is a major exporter in Asia PE market, which may lead to a decrease in the supply of short-term exports,” Yu said.

“In addition, due to the high naphtha cost, the average operating rate of steam crackers and PE plants in Korea has shown a relatively low level. The strikes may exacerbate this situation,” she added.

For polyethylene terepthalate (PET), export deliveries were able to continue this week as some cargoes had been prepared before the strike started, however domestic deliveries faced challenges with the reduced trucking capabilities.

For propylene, the country’s exports may increase should the strike be prolonged as domestic distribution of derivative products becomes disrupted, market sources said.

A senior truckers union official quoted by newswire agency Reuters on Friday said that the number of vehicles entering the complex in the country’s east has been cut to one-tenth of normal levels.

The union also plans more stringent strike action at other petrochemical complexes across the country, the unnamed official told Reuters.

The general strike by CTS under the wing of the Korean Confederation of Trade Unions, was launched on 7 June.

The truckers were demanding the government to extend a freight rate system, which guarantees basic wages to cope with surging fuel costs. The system was due to expire in December.

South Korea’s Ministry of Land, Infrastructure and Transport had expected some 7,500 members, representing about 35% of the CTS union, to go on strike on Friday,

There have been “local transport obstructions in some ports such as Busan Port and Ulsan Port. Carry-out volume is reduced compared to normal”, the ministry said.

Traffic at the Busan port, which accounts for 80% of container activity in the country, was down to a third of normal levels on Friday, Reuters reported, quoting a government official.

At the port of Ulsan – the industrial hub where much of the strike action has occurred – movement of containers has totally been suspended as of Friday morning due to the strike, according to Reuters.

Around 1,000 truckers were protesting at the main complex of Korea’s biggest automotive manufacturer Hyundai Motor in Ulsan on Friday, Reuters reported.

Hyundai operates the world’s largest integrated automobile manufacturing facility in Ulsan which has an annual production capacity of 1.6m units. The strike has halved Hyundai’s production in Ulsan.

The automotive sector is a major downstream industry for petrochemicals.

Focus article by Nurluqman Suratman

Additional reporting by Trixie Yap, Yeow Pei Lin, Hazel Goh and Julia Tan

June 10, 2022

Trucking Strike in South Korea

S Korea truckers’ strike to hit Ulsan petrochemical output; halts port ops

Nurluqman Suratman

10-Jun-2022Full storyRelated newsRelated contentContact us SHARE THIS

SINGAPORE (ICIS)–The ongoing nationwide strike by unionised truckers in South Korea are forcing several producers in the petrochemical hub of Ulsan to consider production cuts amid logistics disruption.

Synthetic rubber giant Kumho Petrochemical is expected to slash production rates at its acrylonitrile butadiene styrene (ABS) and polystyrene (PS) units from the second half of June due to the strike, according to market sources.

HDC Hyundai Engineering Plastics Co is also expected to slash production at its 160,000 tonne/year PS plant in the complex.

While there have been no immediate reports of polyethylene (PE) production losses due to the strike, facilities in Ulsan and elsewhere in the country could be affected if the strike drags on.

The strike by the Cargo Truckers Solidarity (CTS) union entered its fourth day on Friday.

Some PE producers may face pressure to sell prompt cargoes or further reduce their cracker run rates owing to the ongoing strike by truckers.

If the transportation problem persists, “I expect more PE plants in South Korea will cutback or shut down in the short term,” ICIS senior analyst Amy Yu said.

The strike has slowed down the delivery of PE cargoes, raising concerns that some producers might have to lower their downstream operation, to manage their already high inventory if the logistic issues continue next week.

“South Korea is a major exporter in Asia PE market, which may lead to a decrease in the supply of short-term exports,” Yu said.

“In addition, due to the high naphtha cost, the average operating rate of steam crackers and PE plants in Korea has shown a relatively low level. The strikes may exacerbate this situation,” she added.

For polyethylene terepthalate (PET), export deliveries were able to continue this week as some cargoes had been prepared before the strike started, however domestic deliveries faced challenges with the reduced trucking capabilities.

For propylene, the country’s exports may increase should the strike be prolonged as domestic distribution of derivative products becomes disrupted, market sources said.

A senior truckers union official quoted by newswire agency Reuters on Friday said that the number of vehicles entering the complex in the country’s east has been cut to one-tenth of normal levels.

The union also plans more stringent strike action at other petrochemical complexes across the country, the unnamed official told Reuters.

The general strike by CTS under the wing of the Korean Confederation of Trade Unions, was launched on 7 June.

The truckers were demanding the government to extend a freight rate system, which guarantees basic wages to cope with surging fuel costs. The system was due to expire in December.

South Korea’s Ministry of Land, Infrastructure and Transport had expected some 7,500 members, representing about 35% of the CTS union, to go on strike on Friday,

There have been “local transport obstructions in some ports such as Busan Port and Ulsan Port. Carry-out volume is reduced compared to normal”, the ministry said.

Traffic at the Busan port, which accounts for 80% of container activity in the country, was down to a third of normal levels on Friday, Reuters reported, quoting a government official.

At the port of Ulsan – the industrial hub where much of the strike action has occurred – movement of containers has totally been suspended as of Friday morning due to the strike, according to Reuters.

Around 1,000 truckers were protesting at the main complex of Korea’s biggest automotive manufacturer Hyundai Motor in Ulsan on Friday, Reuters reported.

Hyundai operates the world’s largest integrated automobile manufacturing facility in Ulsan which has an annual production capacity of 1.6m units. The strike has halved Hyundai’s production in Ulsan.

The automotive sector is a major downstream industry for petrochemicals.

Focus article by Nurluqman Suratman

Additional reporting by Trixie Yap, Yeow Pei Lin, Hazel Goh and Julia Tan

June 10, 2022

Inventories are in the News

“The Demand For Random Crap Suddenly Vanished, Taking Everyone By Surprise”

by Tyler DurdenThursday, Jun 09, 2022 – 07:00 PM

By Rachel Premack of FreightWaves

At the beginning of 2022, things were economically pretty peachy. Too peachy, one could argue: People were buying so much stuff that our ports and terminals could barely handle the massive import volume. Companies were desperate for someone, anyone, to come work for them. And movie theaters, offices, planes and other locales many eschewed during the pandemic were poised to bounce back; the omicron wave appeared mild compared to previous bouts of the coronavirus.

The vibes were good. Now, the vibes are completely terrible.

More and more spooky recession signs are cropping up seemingly every day, ranging from cooling housing starts to meek GDP growth, all amid the Fed tightening rates. Record-setting inflation – particularly for gas – is only adding to the premonitions, as Vox’s Emily Stewart wrote Wednesday in a piece aptly titled “The bad vibes economy.” But even as things feel bad, many still cast doubt that we’re headed for a recession this year, pointing out persistently low unemployment and the fact that certain indicators, while not as strong as the beginning of this year, are still unusually healthy.

No one is shocked that what goes up must go down. What’s shocking us all is how quickly the situation changed.

Glum transportation indicators confirm the bad vibes

A downturn, if not a full-on recession, is clear in the transportation world. While the rest of the economy debates whether things are that bad, it’s been clear for months to logistics providers that the situation has worsened — and the velocity of that change is still stunning.

The cost to move a container from Asia to a major port in North America or Europe has sunk by 23% since the beginning of this year, according to maritime research firm Drewry. Spot rates have plummeted even faster; marketplace Freightos said rates from China to the West Coast are down 38% month-over-month. FreightWaves forecast this week that ocean shipping volumes will “drop off a cliff” by this summer, based on slumping bookings out of China.

Spot van rates in trucking are down 31% since the beginning of this year, with some truck drivers reporting that rising diesel and plummeting rates have already harmed their business.

Even our mighty railroads are reporting a 3% year-to-date decline in volumes across the board, with only carloads of coal, chemicals and “stone, sand and gravel” (aka, frac sand) increasing.

The pullback in transports has been quicker and swifter than anyone imagined. In the ocean world, carriers have deployed more vessels than ever before, according to research firm Sea-Intelligence. In March, Sea-Intelligence forecast carriers to increase their capacity following Chinese New Year by 20% over 2019 levels. Asia-East Coast services were forecast to grow an eye-popping 40%.

And in trucking, small carriers flooded the market. Since the beginning of the pandemic, the number of trucks available to haul a load is up 10%.

Transporters built up record capacity to move loads that are suddenly shrinking. Even if volumes merely settled to pre-pandemic marks, rather than collapsing to a 2008-like recessionary volume, carriers would still be in trouble.

And this isn’t a trend that’s exclusive to transportation.

Retailers are a little embarrassed right now

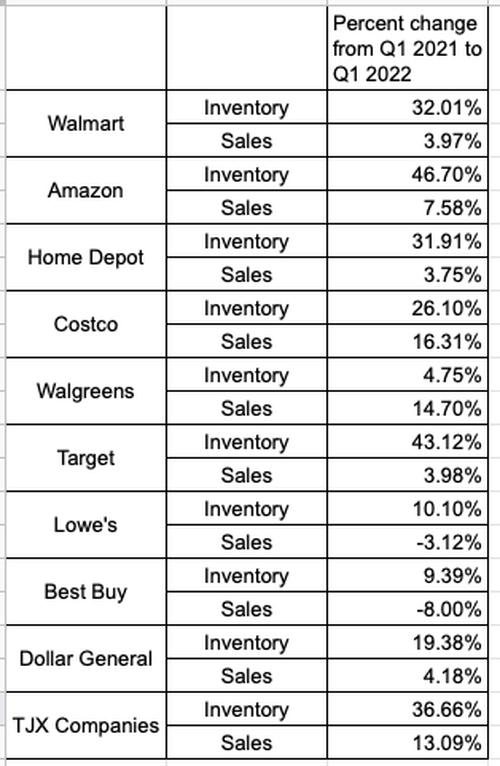

Walmart, Amazon, Home Depot, Best Buy and most every other retailer are having their own mismatch of supply and demand. They stocked up too much this past year. Now they’re struggling with something called “inventory bloat.” It is even more painful than regular bloating, I imagine, if you are a shareholder in a large retail firm.

While we were buying more and more crap, seemingly without any regard for our dwindling savings, our favorite retailers were doing anything to get more product in.

At some point this year, though, the thirst for buying stuff finally quenched. Some of us got spooked by inflation, others got hit by a hefty tax bill and still others decided to spend their apparently boundless cash on trips abroad and fine dining. Or some weird combination of the three.

The retailers weren’t aware that we were all going to stop ravenously buying this quarter, apparently. They quietly kept amassing their own inventories, many of which were still depleted from 2020 and 2021. And concern over another black swan after years of oddities – trade wars, the pandemic and so on – probably drove many transportation managers to keep ordering stuff. Just in case.

Retailers realized this spring that they built up too much. Amazon said in an April call to investors that it had to scale back after doubling its warehouse footprint. Bloomberg reported weeks later that the mega-retailer was quietly trying to end or sublease at least 10 million square feet of warehouse space. It was a stunning about-face for the company that many investors believed had not only endless growth but an unmatchable logistics machine.

It’s not just warehouse space that Amazon loaded up on – it’s the stuff in the warehouses. According to federal filings concerning the first three months of 2022, the value of Amazon’s total inventories increased 47% compared to the same period last year. But its North America net sales only popped 8%.

Amazon was hardly alone in its uncomfortable first-quarter report. Walmart’s inventory jumped 32% from the previous year, compared to a 4% increase in sales. Best Buy’s inventories increased 9%, while sales declined by 8%.

Target really wants you to buy a bunch of televisions and lawn chairs

America’s top retailers messed up – particularly the ones that focus on durable goods rather than groceries. Most of them released their earnings reports last month, saw shares take a beating and moved on.

Target followed that at first. Its earnings report on May 18 fell short of investor expectations, with an anticipated profit margin of 5.3%. Over-the-top inventories of kitchen appliances and electronics were the top culprit. Its stock sank by 25%.

Then, the mega-retailer did something no one was expecting. On Tuesday, Target told investors it anticipated a profit margin more around 2%. It would slash prices on certain goods and cancel incoming orders. It’s highly unusual for a company to slash its profit expectations within weeks of its earnings report.

Target said in its Tuesday press release that the profit slash comes from a need to “right-size” inventories. People aren’t buying items like televisions, outdoor furniture and kitchen appliances like they were last year. Those are some of the delicate, bulky items Target paid dearly to bring over from Asia in 2021, amid record-high shipping rates.

It’s all leading to what Forbes’ Madeline Halpert called “markdown mania,” and not just at Target. Gap is hawking $60 leggings for just $12. Target is selling televisions for 25% off and patio sets at a 52% markdown. In total, shares in consumer staples stocks have tumbled by about 9% from mid-April highs, while consumer discretionary shares are down by about 20% over the same period.

Few of us in the logistics world were surprised. After all, if trucks and ships are moving less stuff, it’s a sign that consumers aren’t buying as much and that manufacturers have curtailed their output.

Sometimes it can be hard for us who toil in logistics to get the attention of lofty economists and traders. Even though I write about the companies that move everything we eat, wear, drink and most any other verb you could think of, I’m still told that I cover a niche industry. The ongoing downturn in trucking seems like it would only affect truckers – never mind the fact that a trucking recession has preceded nearly every recession since the 1970s, per research from freight brokerage Convoy.

The demand for random crap suddenly vanished, taking everyone by surprise

As my colleague Mark Solomon wrote last month on this “inventory bloat,” it’s challenging to forecast demand – even if you’re one of the biggest retailers in the world. We can return to that key metric of inventories-to-sales ratios, which, conveniently, the federal government tracks.

We generally don’t like an inventories-to-sales ratio that’s too high – it indicates that people don’t have the cash to buy stuff. But if it’s too low, like it was through much of 2020 and 2021, it means that there isn’t any stuff to buy. See: The “everything shortage” that dominated headlines last year.

As you can see, the inventories-to-sales ratio is still very low, even if it is creeping up from the nadir of last year. That gives credence to some who argue that a recession isn’t in the cards for this year and could explain why the National Retail Federation declared on Wednesday that it expected port volume to roughly match the crazy numbers seen in 2021. (FreightWaves’ own research, which JPMorgan analysts lent credence to in a Wednesday note to investors, counters that.)

The ratio is more marked when you look at the major consumer goods, as Solomon reported (emphasis mine):

Furniture, home furnishings and appliances, building materials and garden equipment, and a category known as “other general merchandise,” which includes Walmart and Target, among others, reported higher inventory-to-sales ratios, according to government data analyzed by Michigan State.

For the latter sectors, the change has happened fast, according to Jason Miller, logistics professor at MSU’s Eli Broad College of Business. As of November, inventory-to-sales ratios were at pre-COVID levels, Miller said. They have since exploded upward.

To end, I’d like to emphasize that the vibes are abruptly off and no one really knows what’s happening. My colleagues who went to the Gartner supply chain conference in Florida this week found that executives were confused and not feeling very zesty. Transportation managers canceled orders in early 2020 predicting a recession, then found their hastiness left shelves empty and consumers furious. Now that they’ve built back up, customers aren’t buying anymore and their balance sheets are destroyed.

The whiplash is baffling.

https://www.zerohedge.com/markets/demand-random-crap-suddenly-vanished-taking-everyone-surprise