The Urethane Blog

Everchem Updates

VOLUME XXI

September 14, 2023

Everchem’s exclusive Closers Only Club is reserved for only the highest caliber brass-baller salesmen in the chemical industry. Watch the hype video and be introduced to the top of the league: — read more

March 21, 2023

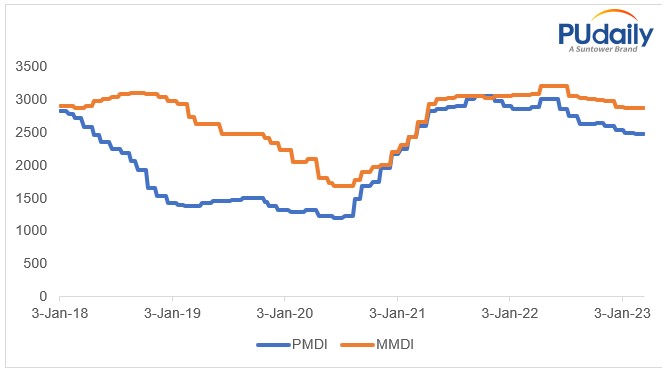

Global MDI Demand Growth Slow Down, MDI Facilities in Europe & USA Idled

PUdaily | Updated: March 17, 2023

On March 2, 2023, Covestro released its 2022 group report: “Fiscal 2022 was impacted by global challenges that had significant and perceptible effects on Covestro’s business performance. In particular, the sharp rise in energy and raw material prices during the year, especially in Europe, put a strain on the company. This was compounded by continuing adverse effects caused by the coronavirus pandemic in China, high inflation and an overall slowdown in global economic growth.” And according to Covestro’s report, the global MDI demand in 2022 was 8,250 k tons, increased by 0.2% year on year. The global MDI demand growth was slow down.

MDI Facilities in Europe & USA Idled, Global MDI Operating Rate Down

On February 21, 2023, Huntsman Corporation disclosed on its fourth quarter 2022 earnings call:

“Our Asian markets, primarily China, did experience modest volume growth in the quarter due to slightly improved demand in insulation and automotive when compared to the fourth quarter a year ago. Europe demand remained subdued…In the short-run, we are idling our smaller MDI line in Rotterdam for an extended period until end market demand improves…In the U.S., we’re seeing similar conditions due to rising interest rates…Our Geismar Louisiana MDI plant, we have closed one of our three lines that represents about 30% of our output.” The company’s spokesperson estimated that the operating rates are presently around 70% globally, which is lower than normal levels.

Huntsman’s MDI capacity in the Netherlands and the United States has reached 470 ktpa and 500 ktpa respectively. It means the idling capacity of Huntsman’s MDI facilities in Rotterdam and in Geismar totals about 300 ktpa.

Due to the declining operating rate of MDI facilities in Europe and the United States, as well as the high cost of upstream energy and raw materials, the PMDI market price in Europe is stable. The contract price is €2,400-2,550 /tonne, and the negotiated price is €2,300 /tonne, showing a weak status between supply and demand.

Construction:

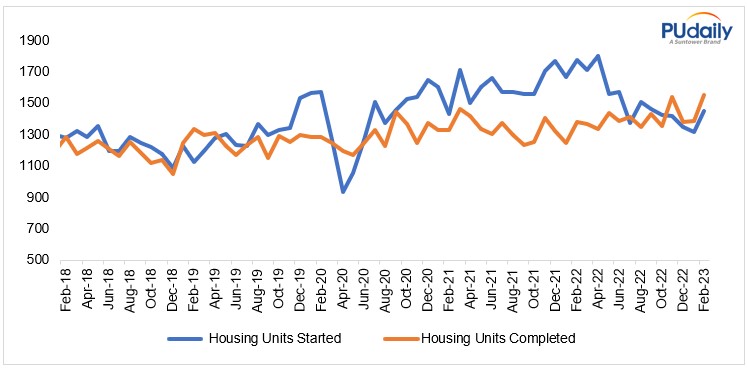

Construction is the most important downstream sector for MDI in Europe and the United States. A major MDI supplier saw that two-thirds of their polyurethane Americas business went into construction-related end markets, approximately half into commercial construction, and half into residential, of which 70% was related to new residential builds.

Americas: New housing starts in U.S. totalled 18.67 million in 2022, a year-on-year decrease of 3.1%, according to Federal Reserve Economic Data. From 2020 to 2021, the US housing market revived rapidly amid Covid-19 pandemic and evolved into a real estate boom since the subprime mortgage crisis of 2007. The current housing boom arises from a combined effect of short cycle (post-Covid policy stimulus) and long-term cycle (inventory cycle after the subprime mortgage crisis). Since the Fed tightened monetary policy in 2022, the real estate market has borne the brunt, and drops in indicators such as home sales and market prosperity are comparable to those in the crisis of 2007-2008. Looking ahead to 2023, the U.S. housing market is expected to weaken, while the margin may be small.

New Housing Starts & Completions in U.S., 2018-2023

Europe:

Market instability has been exacerbated by the war in Ukraine and high inflations, which has dampened the intention to invest in new construction projects. In December 2022, construction output in the Euro Area fell by 2.5% month-on-month, reaching the largest decline in the past 18 months, according to Eurostat. Euroconstruct forecasts a significant slowdown in the growth rate of residential construction in Europe to 1.3% in 2024. This results from stagnation trends in both new residential construction and renovation (in 2024, growth is 1.5% and 1.2%, respectively).

Automobile:

Automobile is another major downstream industry for MDI in Europe and U.S.

Europe: On January 18, 2023, the European Automobile Manufacturers’ Association released a report showing that in 2022, as a result of component shortages, the European passenger car market contracted by 4.6% to 9.26 million units, the region’s lowest level since 1993, when 9.2 million units were registered. Agence France-Presse claimed that 2022 is the third difficult year for the European automobile industry. Since the Covid outbreak and the ensuing supply shortages, a large number of factories and showrooms were shuttered. The semiconductor shortage had not eased even after the pandemic stabilized. In 2022, Germany was the only country of the European market to have recorded growth in auto sales, with 1.1% increase. Sales in Italy, France and Spain fell by 9.7%, 7.8% and 5.4% respectively.

Americas:

U.S.A: Many automakers slashed production due to soaring feedstock costs and ongoing shortages of semiconductors and other components, according to Cox Automotive. Full-year 2022 U.S. auto sales are expected to be near 13.9 million units, a decrease of nearly 8.0% from 2021 and down 20% from the market peak in 2016.

Brazil: In contrast, the auto industry in Brazil performed better. The components shortage in Brazil’s auto industry had eased markedly in 2022, driving growth in the country’s auto output, according to Brazilian Association of Automotive Vehicle Manufacturers (Anfavea). Moreover, the increase in Brazilian auto exports to Latin American countries also boosted the rise in the country’s auto industry. Anfavea currently expects that Brazil’s 2023 auto output would rise by 2.2% to 2.42 million units.

http://www.pudaily.com/Home/NewsDetails/35233

March 15, 2023

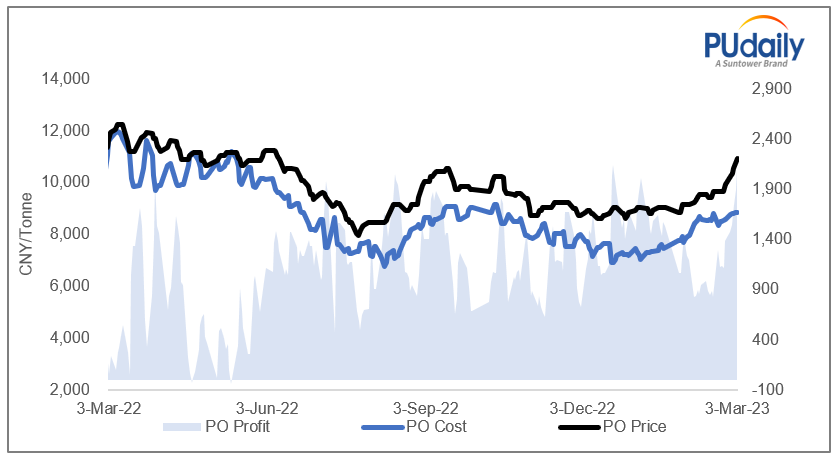

PO Prices Rising in China Dragging Polyol Along for the Ride

Will PO Prices in China Rise to CNY 12,000/tonne in March?

PUdaily | Updated: March 7, 2023

Supply

In February, multiple PO facilities in China experienced overhauls, technical transformation, or output reduction, including Jishen Chemical, Qixiang Tengda, Yida Chemical, Satellite Chemical, Sinopec Tianjin, Sinopec Zhenhai, etc., involving a total capacity of 1.69 mtpa. The capacity utilization was around 60% in February. Moreover, the synchronous maintenance of overseas facilities resulted in a significant shrinkage of imported goods. Therefore, the overall supply of PO in China was tight.

Demand

China’s February manufacturing PMI rose 6.9 percentage points month-over-month to 56.7%, indicating that China’s production activities are accelerating to pick up after getting rid of the impact of Covid-19 pandemic and the Spring Festival factor. Downstream manufacturers gradually recovered operation and saw sales increases in February. Besides, the costs of PO increased as the profit margin of chlorohydrin process further narrowed. As a result, PO prices in China kept moving up since February. On March 6, the prevailing offers of PO in Shandong and North China markets stood at CNY 11,100-11,200/tonne EXW in bulk in cash.

Forecast

In a promising March, polyurethane downstream industries are pinned on new hopes. The market sentiment has grown markedly. Thanks to successively convened exhibitions and consumption-based incentives, the demand is expected to further rise. With the approach of China’s Two Sessions, many local governments have issued control measures for the production and transportation of hazardous chemicals, so that the supply of polyurethane raw materials will be more or less affected. PO prices in China are projected to move around CNY 12,000/tonne.

http://www.pudaily.com/Home/NewsDetails/34965

March 14, 2023

LyondellBasell Commissions World’s Largest PO/TBA Unit

HOUSTON, March 14, 2023 /PRNewswire/ — LyondellBasell (NYSE: LYB) today announces it has successfully started up the world’s largest propylene oxide (PO) and tertiary butyl alcohol (TBA) unit in Texas. These new assets on the U.S. Gulf Coast have an annual capacity of 470 thousand metric tons of PO and one million metric tons of TBA and its derivatives.

“The world-leading capacity of the new plant positions us to meet the growing demand for products essential for modern life,” said Chris Cain, LyondellBasell senior vice president for Global Manufacturing. “Our company strives to be trailblazers in our industry and make positive contributions through our environmental and sustainability initiatives. This project advances our company’s goals and creates value while meeting customer and society’s needs, and it involved a collaborative effort between multiple project teams at Bayport, Channelview and around the world to deliver a project of this magnitude.”

The PO/TBA project is a split facility design, intended to optimize production and leverage synergies shared by the LyondellBasell Channelview Complex located in Channelview, Texas and the LyondellBasell Bayport Complex located in Pasadena, Texas. The 140-acre PO/TBA plant was built at the Channelview Complex, while the associated 34-acre ethers unit, which will convert TBA to oxyfuels, was built at the Bayport Complex.

The project is part of the company’s multi-billion dollar series of investments along the U.S. Gulf Coast. Based on an analysis by the Greater Houston Partnership, the LyondellBasell PO/TBA project is estimated to generate more than $450 million in tax benefits for the county, school district, community college and other local taxing districts over a 10-year period.

The development of LyondellBasell PO/TBA operations began at the Bayport Complex, with the first PO/TBA unit starting up in 1969. Through 50-plus years of global experience with PO/TBA operations and applying new innovations in yield improvement and PO recovery, the PO/TBA plant at the Channelview Complex is the most energy efficient PO/TBA facility in company history.

Propylene Oxide (PO)

PO goes into making polyurethane foam typically used to create mattresses and car and furniture seat cushions. It is also used to make insulation, which can be used to increase the energy efficiency of homes and businesses.

Other common end uses for these products include liquid detergents, toothpaste, cosmetics, paints and spandex fabrics.

Tertiary Butyl Alcohol (TBA)

TBA is converted to produce two ether-based oxyfuels, methyl tertiary butyl ether (MTBE) and ethyl tertiary butyl ether (ETBE). Both MTBE and ETBE are high-octane fuel additives that help gasoline burn more efficiently, reducing emissions from automobiles.

About LyondellBasell

As a leader in the global chemical industry, LyondellBasell strives every day to be the safest, best operated and most valued company in our industry. The company’s products, materials and technologies are advancing sustainable solutions for food safety, access to clean water, healthcare and fuel efficiency in more than 100 international markets. LyondellBasell places high priority on diversity, equity and inclusion and is Advancing Good with an emphasis on our planet, the communities where we operate and our future workforce. The company takes great pride in its world-class technology and customer focus. LyondellBasell has stepped up its circularity and climate ambitions and actions to address the global challenges of plastic waste and climate change. For more information, please visit www.lyondellbasell.com or follow @LyondellBasell on LinkedIn.

https://lyondellbasell.mediaroom.com/index.php?s=43&item=1440

March 14, 2023

LyondellBasell Launches New Company Strategy

HOUSTON, March 14, 2023 /PRNewswire/ — LyondellBasell hosts its Capital Markets Day today at the New York Stock Exchange and is introducing its new long-term strategy which is aligned with the company’s purpose of creating solutions for everyday sustainable living. The company expects to accelerate growth, expand margins and improve returns through its technology leadership, sustainable solutions, and sharp focus on favorable positions in attractive global markets. LyondellBasell is positioning itself to be the company of choice for financial, environmental, social and governance (ESG) minded investors, customers and brand owners. The company is doing this by shaping its businesses to use plastic waste as a valuable source of carbon and creating products and sustainable solutions using circular and renewable materials to address demand.

The new LyondellBasell strategy focuses on growing sustainable value and encompasses three key elements:

- Growing and upgrading the core: Growth will be focused on businesses where LyondellBasell has leading positions in expanding and well-positioned markets.

- Building a profitable Circular & Low Carbon Solutions (CLCS) business: LyondellBasell expects CLCS to grow to at least $1 billion in incremental EBITDA by 2030 with attractive returns by leveraging the company’s existing strengths of scale, market access and technology leadership.

- Stepping up performance and culture: The company will drive improved results by shifting from a singular focus on cost control to a more comprehensive view of value creation and customer centricity.

The company’s strategy is enabled by a value enhancement program (VEP) that is expected to deliver at least $750 million of recurring annual EBITDA improvement by year-end 2025. The VEP expands capacity through low-cost debottlenecks and improved reliability, reduces costs and emissions by saving energy, and increases margins through improvements in procurement, logistics and customer service.

“Our products are an essential part of a safe, healthy and more sustainable living, and I am confident our new strategy will unlock the true potential of our company,” said Peter Vanacker, LyondellBasell CEO. “Our strategy is differentiated by our ability to effectively execute these three impactful elements all at once, driven by our passionate people and enabled by our technology leadership, our exceptional cash generation and strong balance sheet. We believe our core businesses have lasting advantages, and we will grow our advantage through highly focused and disciplined reinvestment. This will deliver strong profitable growth and deliver compelling returns to our shareholders.”

While the new strategy was announced today, LyondellBasell began taking action on its new strategy in 2022 by:

- acting decisively to exit the refining business and divest its Australian polypropylene business;

- improving customer focus by forming its Customer and Commercial Excellence team;

- establishing the CLCS leadership role and business;

- implementing and expanding its VEP; and

- taking significant steps forward in its journey to reduce greenhouse gas emissions.

While LyondellBasell intends to cease refining operations at its Houston Refinery, the company is evaluating future investments at the site. LyondellBasell is analyzing the potential to retrofit the refinery to build up its CLCS business, which will also keep jobs in the region and align with the company’s strategy to leverage existing assets that are strategically located within the LyondellBasell portfolio.

Today, LyondellBasell also announces the decision to explore strategic options for its U.S. Gulf Coast-based ethylene oxide & derivatives (EO&D) business. While the EO&D business provides positive cash generation, it is not a business where the company seeks a leading long-term position. This decision is another example of how the company’s new strategy has a laser focus on its core businesses.

With this new long-term direction, LyondellBasell aims to unlock value, increase earnings and continue providing strong returns for investors. LyondellBasell seeks to build businesses with enduring competitive advantages, sharpen its focus on leading positions, cement its position as the preferred supplier for customers, and establish the company as a profitable leader in the growing circular and low carbon solutions market.

https://lyondellbasell.mediaroom.com/index.php?s=43&item=1439